(Also check out Warn’s Winch Guide)

Winch Sizes

The first and foremost factor to consider is the winch capacity. When it comes to a winch, higher winch capacity is always better! The heavier the vehicle, the more powerful winch you’ll need. Your winch should be able to pull at least 1.5 times the weight of your vehicle.

You can calculate it by taking the gross vehicle weight and multiply it by 1.5. This is the minimum rating, but certain factors can make your winch capacity be exceeded.

GVWR = Base Weight + Passengers / Cargo

Best winch Size >= GVWR x 1.5

So, if your vehicle weighs 1.8 metric tons (4000 lbs) then choose a winch having at least 2.7 metric tons (6000 lbs) capacity.

The 1.5X rule is the industry standard. But for a better safety, you should pick one that has the capacity more than that.

On a 1983-2011 Ford Ranger, we recommend you use at least an 8,000 lb winch. On the 2019 and newer Ford Ranger, we would recommend a 9,500 lb or larger winch.

Winch Types

The main difference between a hydraulic and an electric winch is the power source. Hydraulic winches are powered by the vehicle power steering pump. Electric winches are linked to the vehicle battery and electrical system.

The electric winch is the most common and widely used winch type. They’re quite durable and often less expensive than the hydraulic winch – but if you use them for a longer time, they can overheat. So, if you have to use the winch all day long, then you may face the problem with your vehicle’s electrical system. In this case choose a hydraulic one, otherwise, electric winches are a better option.

If you plan to use a winch frequently, then the hydraulic winches are the best choice. They don’t have problems of overheating, but they have some downsides too. This type of winch isn’t available everywhere – only a few manufacturers produce hydraulic winches. While using this winch, the engine must be running because they’re operated with the power steering pump.

Cable / Rope Options

There are lots of debate when it comes to choosing between synthetic rope or steel cable.

Steel Cable

Steel cable has been the industry standard for decades and is known for its ruggedness and lower initial cost. This type of cable is affordable, durable and very easy to maintain. A downside is that steel cable weighs a lot more than synthetic rope. Steel cable is ideal to use in highly abrasive terrains. If you often drive through sand, mud and rocks, then steel rope is the good choice for you. While handling the rope, you should wear heavy gloves to protect your hands.

Durability: It is highly resistant to abrasion from rocks and rough terrain, and unaffected by UV light, making it a “set it and forget it” option in some conditions.

Cost: Steel cable is generally more affordable upfront than synthetic rope.

Handling & Safety: It is heavy and can develop dangerous, sharp metal burrs (called “fishhooks”) over time, requiring the constant use of heavy gloves. It also stores a significant amount of potential energy when under tension, which is a major safety risk if it snaps.

Maintenance: Steel can rust and kink if not maintained with a light coating of oil and spooled properly, which can decrease its strength. A winch damper should always be used with steel cable for safety.

Synthetic Rope

Synthetic rope is a modern choice that prioritizes safety and user experience. It’s made from high-modulus polyethylene (HMPE) and is a great product for most vehicle recovery situations.

Safety: The primary advantage. If the rope breaks under load, it has less stored kinetic energy and will typically fall harmlessly to the ground, rather than whipping back dangerously like a steel cable.

Weight: It is significantly lighter than steel, making it much easier to handle and reducing the overall weight on the front of your vehicle.

Handling: Synthetic rope is flexible, won’t develop sharp burrs (which can cut hands even through gloves), and is easier to spool onto the winch drum.

Maintenance & Durability: It is resistant to rust and corrosion, and it floats on water. However, it is susceptible to damage from abrasion against sharp rocks, heat buildup in the winch brake drum, UV exposure, and chemicals, requiring regular cleaning and inspection, as well as the use of an abrasion sleeve.

(Synthetic Winch Rope)

Winch Motor Type Explained

Winches come with two types of DC motors: Permanent Magnet Motors (PM) and Series-Wound Motors (WM).

All DC winch motors have a set of coils inside them which is called the armature. Inside this armature, there is either another set of field coils or a set of permanent magnets which is called stator.

The stator creates a magnetic field which causes the armature (or rotor) to rotate when an electric current flows through it.

The higher the horsepower rating, the more power and torque the motor will have. The motor’s horsepower has a direct effect on both pulling power and line speed.

Permanent Magnet Motors

The stator of permanent motor uses permanent magnets and there are no field coils. They cause very little strain on the battery than series-wound motors and typically cost less. They offer good pulling power and performance.

Permanent magnet motors are better suited for light to medium duty winching jobs. As permanent magnet motors are less tolerant to heats, winching time and load should be taken carefully. This type of motor can lose power in extremely cold conditions.

Series Wound Motors

When it comes to the series-wound motor, the field coils are connected in series with armature coil. They are very powerful and generate the most torque for a given current. SW motor uses more current over a PM motor because they use field coils to generate the magnetic field.

Series wound winches are heavier duty winches which will help you to overcome the most difficult recovery situations. They usually cost more and sometimes require upgrading the alternator, battery or other components for reliable performance. The series-wound is a better option for cold weather or heavy-duty use.

Winch Gear Types Explained

Winches mainly come in three different types of gear systems. They are: Planetary gears, Worm gears, Spun gears.

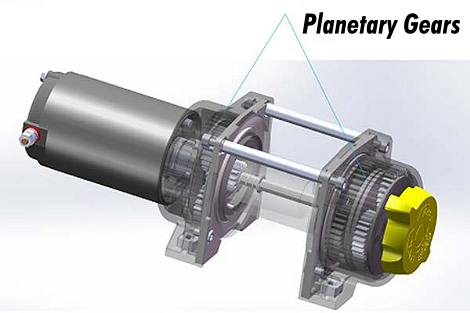

Planetary Gear

(Planetary Gear)

Planetary gears are the most common and most popular for automatic transmissions. They are named planetary gear because they look like the sun with some revolving planets. It’s actually a gear set inside or on a large gear.

Nowadays most electric winches use the planetary gear. They are typically more compact which allows for less cost and weight. They offer strength and smooth operation with good resistance to torque loads. The planetary gear systems have a power transfer efficiency of 65%.

One of the negative points of planetary gear is heat accumulation on the brake unit.

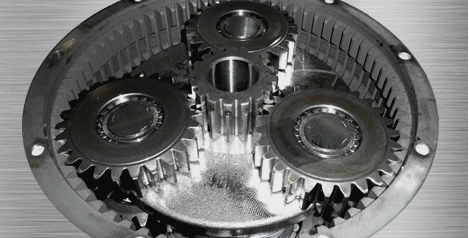

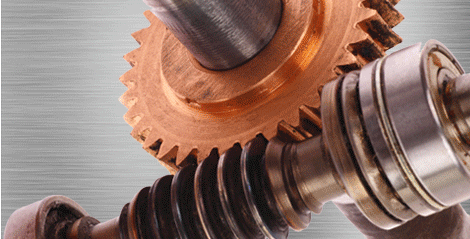

Worm Gear

(Worm Gear)

Winches with worm gear are ideally suited for workman or industrial applications. They’re not generally used on off-road winches. Their special features are lowering and load holding. That’s why they’re a popular choice for tow trucks.

The worm gear has a power transfer efficiency of 35 to 40%. They provide very high reliability, reduction, and built-in braking mechanism. They’re simpler and stronger than other gear systems.

Their downside is that they pull far slower than electric winches.

Spur Gear

Spur gear has a power efficiency of 75 percent. They consist of one small wheel-shaped gears and one large wheel-shaped gears. The smaller gear connected to the motor and makes the larger one to run. They’re not expensive but still perform well.

Spur gear winches have fairly low amperage draw. But they are fast. Only the legendary WARN M8274, which is one of the top winch manufacturers, has a spun gear still on the market.

Mounting Options

This is one of the most important considerations. There are three popular options that you can mount your winch.

Bumper mount: This is the simplest option mounting option. They offer the most versatility. They’re super easy to install.

Multi-mount: This is a little more complex than the first one. A Multi-Mounted winch is not very durable because of the mounting point. The multi-mounted winch is perfect for you if you’re one of them who want the security a winch provides without mounting it to your vehicle permanently.

Winch bumper: This mounting option is becoming popular day by day as they look like really part of your vehicle. They also provide protection to your vehicles front side.

Winch Recommendations

Warn Winch

The WARN VR EVO 10 10,000 lb. winch is the cheapest Warn winch you’re going to find to winch your Ford Ranger / Bronco II and comes with a $600-$650 price tag. If you want a legendary Warn winch and not break the bank, this is the winch to get.

Smittybilt Winch

The SmittyBilt XRC-9.5K Winch (SB97495) has found its way onto a lot of off-road vehicles. I have it on both of my Ranger’s and even had one on my car trailer. You can normally buy these for less than $400. If you’re willing to spend $500-$600, the SmittyBilt XRC GEN 3 9500 SYNTHETIC (SB98695) will get you a 9,500 lb. winch with a synthetic rope.

X-Bull Winch

X-Bull winches have been gaining popularity and offer a 10,000 and 13,500 winch. The X-Bull 13500 XRS Series 13.5K winch shown below with synthetic rope can be had for under $500 making it the hottest winch deal on the market.

Winch Recovery Kit

If you buy a winch, make sure you get a winch recovery kit. A well-equipped recovery kit provides the necessary tools to manage different recovery scenarios safely. The following items are considered essential by TheRangerStation.com and other off-roading experts:

Tree Trunk Protector/Anchor Strap: This is a wide, non-elastic strap used to wrap around a tree or other solid anchor point. It protects the tree from damage and provides a secure attachment point for your winch line or shackles. A minimum width of 3 inches is recommended for tree protection.

Shackles (D-rings or Soft Shackles): These are used to connect different components of your recovery system (e.g., connecting a strap to an anchor point or to your vehicle’s recovery points). Soft shackles are lightweight and safe, while heavy-duty metal D-ring shackles are also a common, reliable choice. Ensure they have a clearly stated working load limit that is at least 1.5 to 2 times your vehicle’s Gross Vehicle Weight Rating (GVWR).

Snatch Block (Pulley Block): A snatch block is a pulley system that allows you to change the direction of your pull or double the pulling power of your winch by creating a mechanical advantage. The rating of the snatch block should be at least double your winch’s capacity.

Winching Gloves: A good pair of heavy-duty gloves is critical for hand protection from burrs on steel cable or general environmental hazards during the rigging process.

Winch Line Dampener: This safety device, which can be a purpose-built bag or a heavy blanket, is placed over the center of the winch line. In the event of a cable or rope failure, the added weight helps direct the line to the ground, preventing it from whipping back violently.

Recovery/Tow Strap: Is a high-strength, non-elastic strap designed to pull a free-rolling vehicle behind another. Unlike kinetic recovery ropes, they are made to be rigid for steady, controlled towing on flat surfaces like roads. It is recommended to choose a strap with a breaking strength at least 3 times the weight of the vehicle being towed.

Kinetic Recovery Rope: The rope functions similarly to a heavy-duty rubber band. As a recovery vehicle drives forward with some slack in the line, the rope stretches—typically up to 20% to 30% of its original length. This stretching process:

- Stores Energy: Momentum from the recovery vehicle is converted into potential energy within the rope’s fibers.

- Reduces Shock: The elasticity absorbs the initial jolt, protecting the chassis and recovery points of both vehicles from sudden, damaging impacts.

- Multiplies Pulling Force: When the rope reaches its maximum stretch, it recoils, releasing the stored energy to provide a powerful, gradual tug that helps dislodge the stuck vehicle.

Manufacturers recommend choosing a rope with a Minimum Breaking Strength (MBS) that is roughly 3 times the gross weight of the vehicle being recovered.

Recovery Points

Does your Ranger have proper recovery points on the front AND rear of the truck? A safe and effective vehicle recovery point is specifically engineered to handle the massive, often dynamic forces of extracting a bogged vehicle.

A good recovery point consists of the following essential elements:

1. Rated Load Capacity

- Verified Rating: The point must be “rated,” meaning it has been physically tested or modeled to withstand specific load limits, often stamped directly on the component.

- Safety Factor: High-quality points, like those from ARB, are often designed to work with a specific “recovery train,” such as a 4.75-ton rated shackle and 17,600 lb snatch strap.

2. Chassis-Mounted Construction

- Direct Frame Attachment: Safe points are bolted directly to the vehicle’s chassis rails using high-tensile bolts (typically Grade 10.9 or M14).

- Multiple Bolt Points: Unlike flimsy tie-downs held by one or two small bolts, rated recovery points often use multiple bolts—sometimes up to six—to spread the load across the frame.

- No Bumper Mounting: Recovery points should never be attached only to a standard factory bumper, which can easily tear off.

3. Purpose-Built Design

- Closed Loop or Secure Hook: They usually feature a thick steel loop designed to accommodate a bow shackle or soft shackle.

- High Visibility: Many are powder-coated in bright colors like red or blue so they are easy to find when covered in mud or in low-light conditions.

- Angled Pull Capability: Engineered points are designed to handle forces from multiple angles (longitudinal and latitudinal), whereas standard hooks may fail if pulled sideways.

4. Safe Location

- Balanced Distribution: Ideally, a vehicle should have two points at the front and two at the rear.

- Bridle Compatibility: Using two points allows for a bridle (equalization) strap, which halves the load on each individual point and prevents chassis twisting.

Critical Safety Warnings - NEVER Use a Tow Ball: Trailer balls are designed for towing, not recovery. They can shear off under the “snatch” force of a recovery, becoming a deadly “spherical missile”.

- Hitch Receivers: A 2-inch receiver can be a very strong point, but only if you use a Rated Hitch Shackle Block instead of the tow ball.

JDMSPEED Tow Hook Heavy Duty D-Ring Set

Dyno Racing Front Tow Hook Shackle Mount Kit

Links

Related Articles

What Most People Don’t Know About Winching

Last Updated:

About The Author

Jim Oaks is the founder of TheRangerStation.com, the longest-running Ford Ranger resource online since 1999. With over 25 years of hands-on experience building and modifying Ford Rangers — including magazine-featured builds like Project Transformer — Jim has become one of the most trusted authorities in the Ford Ranger off-road and enthusiast space.

Since launching TheRangerStation.com, Jim has documented thousands of real-world Ranger builds, technical repairs, drivetrain swaps, suspension modifications, and off-road adventures contributed by owners worldwide. TheRangerStation.com has been referenced in print, video and online by enthusiasts, mechanics, and off-road builders looking for practical, and experience-based information.