PetroleumJunkie412

Official TRS EV Taunter

Supporting Member

TRS 20th Anniversary

TRS Event Participant

- Joined

- Oct 31, 2018

- Messages

- 7,826

- Reaction score

- 6,565

- Points

- 113

- Location

- Dirtman's Basement

- Vehicle Year

- 1988

- Make / Model

- Ranger

- Engine Size

- 2.9l Trinity

- Transmission

- Manual

- 2WD / 4WD

- 4WD

- My credo

- Give 'yer balls a tug. Fight me.

@Jim Oaks, trying to set this up as a info page on 2.9 area of tech section. Want to get some feedback here first.

Now that we've let the 2.9 heads jokes run their course, I am moving on into figuring out how to port these things as part of my build. If I'm going to push the envelope on this engine, I want to do as much as possible now so as to not regret it later.

Snoranger has been a great help so far (you suck Bobby ) on helping me look at these things.

) on helping me look at these things.

There's almost nothing out there on it. Pruett gives one sh*tty paragraph and diagram on the intake side only,and as far as exhaust, his only comment:

"get rid of the egr bumpand it's all sh*t and let's not discuss it further other than 220 grit and don't think about it."

(pretty sure that's a valve cover bolt boss there Sven, but uh, sure, you gave the world Hemi so we'll play along)

Well sven. I disagree. Strongly.

Theres ponies to be had in them ports.

Pruett was probably correct for n/a and carbureted with his comments.

My engine is being built to handle 21psi at 7000 rpm on sequential efi. His advice doesn't apply here.

So. This is what I think I know about porting. I'm probably wrong. I'm not a mechanic. I'm a computer nerd that f*cks with old engines. Please chime in..

From my understanding, when running tbi/carb n/a, the goal is to rely on what oem gave you and cause airflow to scavenge itself. With A perfect job on intake runner shape and path and other necessary modifications, a volumetric efficiency of >100 is possible, and is evidence of a perfect intake design for a given rpm range. Air will develop minute levels of boost when entering the combustion chamber if the combination of displacement, rpms, intake runner shape, intake runner length, valve selection, crank throws, etc are tuned perfectly. This is why variable length intake runners work. When you can adjust runner shape and length on the flu, you can keep optimal volumetric efficiency.

I now see the beauty in the massive carbureted engines of the Golden age of drag racing. The lifetimes that have gone into perfecting that is awe inspiring. I am humbled.

With fuel injection, same principal, sorta.

Efi goal seems to be to force your fuel to become atomized as quickly as possible when entering the combustion chamber. Tbi/carburetor has an advantage of higher atomization. Mfi wins out due to precision of control. Intake runners are tuned around the injectors to atomizer fuel as fast as possible. Multi hole injectors help this, so does coarse textures around your intake ports so you can get a wall wetting effect. Off gassing fuel droplets means atomization. Atomization means better burn.

This is how I ****Ed up the first lower I ported. I hogged ports and trimmed down injector bosses. Which led to carbon. I learned my lesson.

Injector bosses provide turbulence. Tighter turns and twisting ports creates turbulence. Blend to just shy of gasket surface. Blend within 1/4 inch, not 3 inches. scuff with 80-150-180 and send it. Like don't waste time in the runners. Bust up the droplets. That's the goal. The bare coarse aluminum will do that once you break the casting skin. That's all it needs.

Side note:

I see why gdi is so cool now. It's insane how perfect you can get them. You can form different types of combustion in the chambers depending on your piston tops and injector programming. The level of complexity is beautiful. And I still ****ing hate it.

So. I read somewhere that if you're dealing with a terrible runner design head, like the 460, take silicone castings first, then if in doubt then look, for photos of a cut up head.

Pruett didn't talk about this. I could find no forum posts, so I took some silicone castings.

Guess what??

Yeah they look obscene. It's the f*cking apocalypse, all they had was purple, cut me some slack

Easy AF to do. Silicone molding kit from Amazon. Mask with compatible tape (read f*cking instructions). I used powder coat masking tape, worked. Brush ports down with carnuba wax, follow silicone instructions, pop out when cured.

There. Tech section article. Send it.

Anyway.... They look like sh*t!

So then they suggested to find photos of a cut up head when in doubt.

And then I couldn't find photos of a cut up head. And that's a whole Lotta doubt in those purple ports...

Oh. And another thing.

For all these head cracking rumors, I see very few photos... Hell, photos of my set of blown ones posted here has come up in my searches.

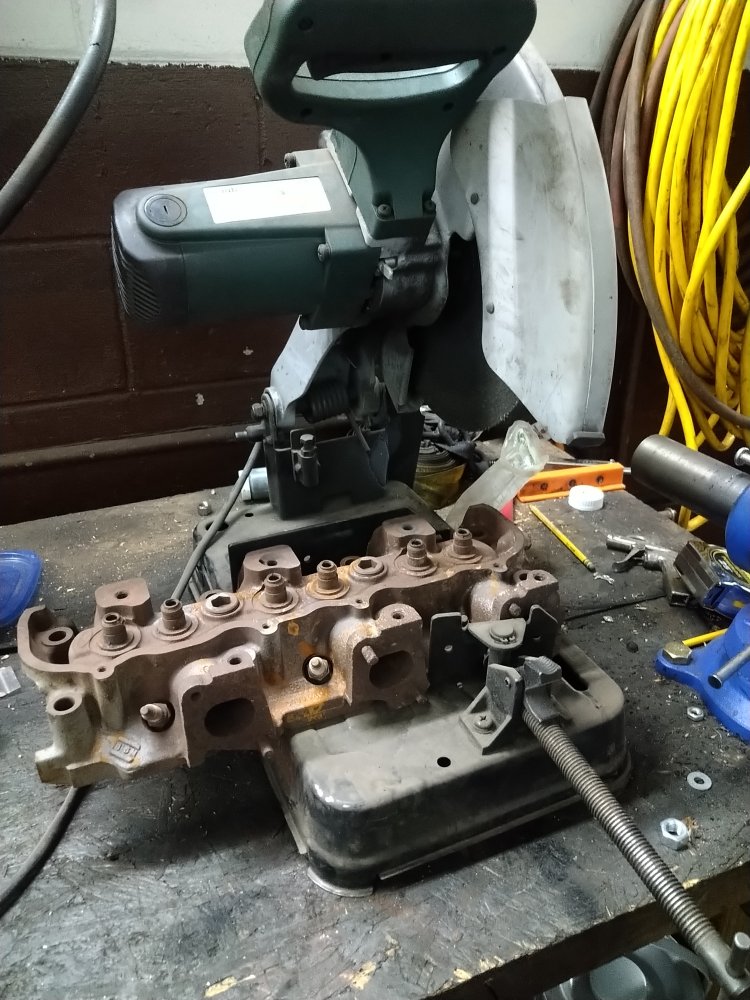

Here's the head perched on the saw, head courtesy of @lil_Blue_Ford.

See how it cracked on the back half, but not on the decks? That's a non stress relieved or machined surface with the mother of all coolant pouches in it. If it's half full and builds up steam.... Boom.

It was half full. It built up steam.

Because casting residue and a horrible head gasket didn't allow coolant to flow.

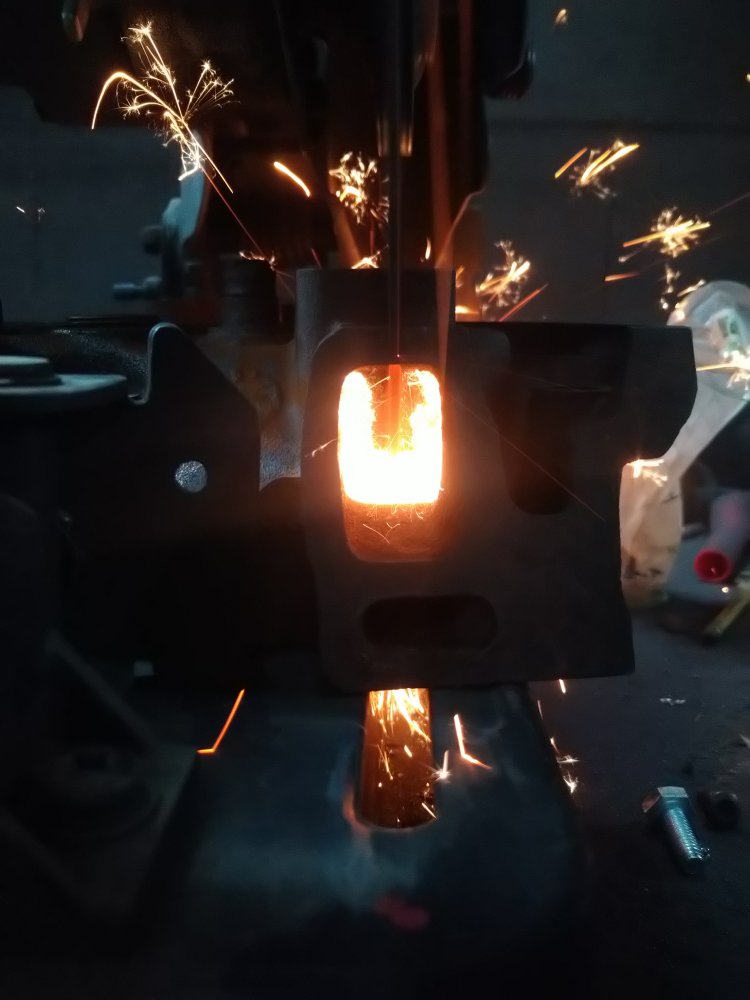

That's after being run through my commercial parts washer, descaled with aluminum oxide, and cut in half with a chop saw. There's still ****ing casting residue.

It wasn't a bad f*cking design, it was p*ss poor quality control.

**** your 4.0.

Ok I feel better.

Anyway.

Here's photos of a blown 2.9 head cut into port runner profiles.

This may become my new avatar:

Profiles:

Just hit me how nice this one came out:

Well. There you have it.

And there where I'm at as of now. Looking for suggestions on shape and porting.

I think I can get away with leveling valve guide bosses and blending. But other questions about supporting valves, wear, etc.

If it's OK with @snoranger, I'll upload his suggestions, along with pruetts terrible sketch.

Now that we've let the 2.9 heads jokes run their course, I am moving on into figuring out how to port these things as part of my build. If I'm going to push the envelope on this engine, I want to do as much as possible now so as to not regret it later.

Snoranger has been a great help so far (you suck Bobby

There's almost nothing out there on it. Pruett gives one sh*tty paragraph and diagram on the intake side only,and as far as exhaust, his only comment:

"get rid of the egr bumpand it's all sh*t and let's not discuss it further other than 220 grit and don't think about it."

(pretty sure that's a valve cover bolt boss there Sven, but uh, sure, you gave the world Hemi so we'll play along)

Well sven. I disagree. Strongly.

Theres ponies to be had in them ports.

Pruett was probably correct for n/a and carbureted with his comments.

My engine is being built to handle 21psi at 7000 rpm on sequential efi. His advice doesn't apply here.

So. This is what I think I know about porting. I'm probably wrong. I'm not a mechanic. I'm a computer nerd that f*cks with old engines. Please chime in..

From my understanding, when running tbi/carb n/a, the goal is to rely on what oem gave you and cause airflow to scavenge itself. With A perfect job on intake runner shape and path and other necessary modifications, a volumetric efficiency of >100 is possible, and is evidence of a perfect intake design for a given rpm range. Air will develop minute levels of boost when entering the combustion chamber if the combination of displacement, rpms, intake runner shape, intake runner length, valve selection, crank throws, etc are tuned perfectly. This is why variable length intake runners work. When you can adjust runner shape and length on the flu, you can keep optimal volumetric efficiency.

I now see the beauty in the massive carbureted engines of the Golden age of drag racing. The lifetimes that have gone into perfecting that is awe inspiring. I am humbled.

With fuel injection, same principal, sorta.

Efi goal seems to be to force your fuel to become atomized as quickly as possible when entering the combustion chamber. Tbi/carburetor has an advantage of higher atomization. Mfi wins out due to precision of control. Intake runners are tuned around the injectors to atomizer fuel as fast as possible. Multi hole injectors help this, so does coarse textures around your intake ports so you can get a wall wetting effect. Off gassing fuel droplets means atomization. Atomization means better burn.

This is how I ****Ed up the first lower I ported. I hogged ports and trimmed down injector bosses. Which led to carbon. I learned my lesson.

Injector bosses provide turbulence. Tighter turns and twisting ports creates turbulence. Blend to just shy of gasket surface. Blend within 1/4 inch, not 3 inches. scuff with 80-150-180 and send it. Like don't waste time in the runners. Bust up the droplets. That's the goal. The bare coarse aluminum will do that once you break the casting skin. That's all it needs.

Side note:

I see why gdi is so cool now. It's insane how perfect you can get them. You can form different types of combustion in the chambers depending on your piston tops and injector programming. The level of complexity is beautiful. And I still ****ing hate it.

So. I read somewhere that if you're dealing with a terrible runner design head, like the 460, take silicone castings first, then if in doubt then look, for photos of a cut up head.

Pruett didn't talk about this. I could find no forum posts, so I took some silicone castings.

Guess what??

Yeah they look obscene. It's the f*cking apocalypse, all they had was purple, cut me some slack

Easy AF to do. Silicone molding kit from Amazon. Mask with compatible tape (read f*cking instructions). I used powder coat masking tape, worked. Brush ports down with carnuba wax, follow silicone instructions, pop out when cured.

There. Tech section article. Send it.

Anyway.... They look like sh*t!

So then they suggested to find photos of a cut up head when in doubt.

And then I couldn't find photos of a cut up head. And that's a whole Lotta doubt in those purple ports...

Oh. And another thing.

For all these head cracking rumors, I see very few photos... Hell, photos of my set of blown ones posted here has come up in my searches.

Here's the head perched on the saw, head courtesy of @lil_Blue_Ford.

See how it cracked on the back half, but not on the decks? That's a non stress relieved or machined surface with the mother of all coolant pouches in it. If it's half full and builds up steam.... Boom.

It was half full. It built up steam.

Because casting residue and a horrible head gasket didn't allow coolant to flow.

That's after being run through my commercial parts washer, descaled with aluminum oxide, and cut in half with a chop saw. There's still ****ing casting residue.

It wasn't a bad f*cking design, it was p*ss poor quality control.

**** your 4.0.

Ok I feel better.

Anyway.

Here's photos of a blown 2.9 head cut into port runner profiles.

This may become my new avatar:

Profiles:

Just hit me how nice this one came out:

Well. There you have it.

And there where I'm at as of now. Looking for suggestions on shape and porting.

I think I can get away with leveling valve guide bosses and blending. But other questions about supporting valves, wear, etc.

If it's OK with @snoranger, I'll upload his suggestions, along with pruetts terrible sketch.

Attachments

-

118.1 KB Views: 128

-

117.4 KB Views: 130

Last edited: