- Joined

- Dec 26, 2025

- Messages

- 12

- Points

- 101

- City

- Sandpoint

- State - Country

- ID - USA

- Other

- 97 Outback 5MT

- Vehicle Year

- 91

- Vehicle

- Ford Ranger

- Drive

- 4WD

- Engine

- 4.0 V6

- Transmission

- Manual

TFI was part of the older systems, the 91 4.0 doesn’t use it, but there is a module that may or may not be affecting things. I’m not exactly sure where it’s located on the Ranger, it’s been awhile since I’ve looked at it because it’s far more reliable than the old TFI. When I converted my Choptop to essentially a 91 4.0, I just found a handy spot on the core support and bolted it in. I suppose anything electronic could fail after over 30 years though…

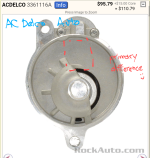

The ignition module is mounted right next to the battery on the front side of the engine bay (not sure if it would be correct to call it the bumper support or not?). I already tried replacing mine because I saw RA had them for a much better deal than anywhere else and figured I would snatch it up on the off chance it was a pricing error, plus they seem to becoming hard to obtain new.

Didn't change the behavior. I actually think I may have gotten the last two in RockAuto's inventory.. first one they shipped didn't arrive so I had them ship another one. The first did eventually end up showing up and I decided to just pay the $50 to keep it rather than shipping it back. So I have 2 new ones and the OEM one. Only new one I see for sale now is from AutoZone for $240 so I am pretty happy having spent about $100 to get 2 of them.

Actually in general I have been holding onto my OEM parts that I pull off, so I still have the original crank sensor, ignition module, and a couple of other odds and ends.

Despite what it says by my name (there was a big forum reset in 07), I’ve been here since about 02.

Whoa, you've been on this forum for about as long as I have been roaming this earth.