I've ran mismatched heads and ports before with little noticeable effects on performance or fuel economy (with a carburetor)...I'm sure it could have been better but it wasn't like I was stopping for fuel every few blocks or so starved for HP that I had to drive in the slow lane.

Yes, carburetor...that's the problem (or the non-problem, in that case). Since the fuel atomization takes place at the carb, then all the vacuum action of the cylinders is pulling pre-mixed air and fuel through the mismatched port. Whatever it can get, it gets, and as you've noted you got a working result.

With port injection, the fuel is being shot in pretty much after the air encounters a bunch of turbulence right at the port on the head...assuming the injector isn't facing a steel wall. I don't understand the complex physics and engineering involved enough to just look at it and say "yep it'll go". Logically, the air velocity inside the port on the head will be higher than in the manifold runner because of the reduction in size. So maybe it will work well.

That performance you described sounds like an ideal situation for a daily that needs to hit the highway. I'm rather fortunate in that my daily commute isn't even long enough to hit operating temperature, but my work is in an area that is not bike, walking, or public transit-friendly. It's part of why I can afford commuting in 4000lbs 302-powered cars when I'm not in the Ranger.

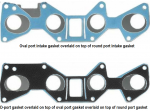

What I would suggest is to make impressions of the actual opening of the intake and overlay that on the head to see if there will be obvious problems with the injectors spraying into obstructions that you may be able to reduce with a bit of porting.

There is quite a bit of material around the edges that can be removed before compromising the integrity of the walls. Exactly how much I'm not exactly sure but maybe someone who has gone too far can elaborate on.

My intent is to take the 2.0 gasket as a template of what the 2.0 head looks like, put it up against the 2.3 EFI intake aligned with the bolt holes, and take straight-on photos so I (we) can figure out where the injectors are pointing.

Logically, they should be aiming right at the intake valve, and since the intake valve is in the same spot in all the heads (smaller on the 2.0, but still in the same spot...), maybe no issue. But the ports are so much bigger on the oval port heads that I really don't want to assume here.

Hogging out metal to make the ports match better would absolutely solve the problem of port alignment, no question. But if I'm taking a cylinder head off to port it out, it's not going to be for a Frankenstein engine with blowby. That's the whole problem here. The goal is to have the

information all worked out, and a concrete, viable plan ready to go before moving on it, to minimize the time and "figuring it out" that has to go into it when it's time to move on it. Talk and research doesn't cost me anything tangible. Hands-on work costs me real effort, and money buying the parts. Hence all the discussion before I even think of buying an intake. Plus there are none available at the moment, so there's that part too.

Those prices you list are way lower than around this area and if it was my dime I'd pick up what I needed and have enough to splurge on a bit of testing and rework on the head.

If you want to salivate over car part prices...

Parts Galore &

Ryan's Pick-a-Part are the local offerings I frequent. Inventory on the latter is out of date, almost all of the listed Rangers are missing.

My threshold for viability here is simply "if I slap this mess together, will it run well enough to DD, understanding that highway driving is less than 10% of the km I put on a vehicle but does need to be possible?"

If there is no solution that can be assembled out of parts that exist without alteration, the project immediately crosses the line of viability to the point where it isn't. I don't mind pulling parts off 12 different donor vehicles to get the right match of pieces to make a bolt-together solution, but as soon as actual alterations (e.g. irreversibly cutting out material) happen...that's a line I don't want to cross.

The next challenge is still going to be the crank position sensor mounting, so if you happen to have any info or pictures that show how that mounts to the engine, this doesn't seem to be something people take a lot of photos of...

My truck is an 85 EFI 2.3, with California emissions. The IAC is mounted to the air cleaner box, with a tube twinned to the air intake for the MAF airflow. There is a 90 degree elbow on the side of the throttle body where the tube is clamped. The air feed is a large diameter rubber/fabric tube. It has no bellows or corrugations like the later models.

Ah! That explains why this looks so...weird:

https://i.imgur.com/QhnxtBs.jpg, and I found it in

this thread.

If you can take any photos that illustrate it better (perhaps what the air cleaner box looks like/how the IAC works) I'd be very appreciative.

Does the upper bolt to the lower with the same (or approximately the same) 4-hole, square-ish pattern seen on newer years also? If so, then an upper intake off a truck with the "normal" IAC setup may be able to mate with that lower intake.

Need 85-87 (Ranger) lower intake because coolant passage in the middle. But upper intake and throttle body maybe can come from something like...a 93? In which case the entire MAF intake ducting and air cleaner can be used as-is.

Given that it is a MAP, the airflow is not known, and engine fuel feed is calculated, table based, from what I have read. Will 300cc make that much of a difference? Will the aim of the injectors matter that much? Can the O2 sensor modify the fuel flow to counter the reduced volume of air(14%-ish) to make it proper ratio? There is a limit to trim levels, and I don't know, but it might.

The details are all kind of "squishy" unfortunately. How much can Speed Density (MAP) compensate for in displacement? I dunno.

How much of an airflow restriction does the 2.0 have vs the 2.3? I dunno.

Is there a "linear" way to apply less fuel per displacement? I dunno.

I do know that I'm expecting it to be a bit rich (300cc displacement worth of fuel rich, which is not much) in all conditions when the computer is in open loop. The O2 is ignored (completely?) until it goes into closed loop. Once the O2 comes into the picture, the computer "should" be able to cut back on fuel because it sees that the exhaust is rich. The problem is that if the computer knows it is dumping too little fuel for the fuel map table for a "2.3", it might get upset that it has to put that much less fuel in. I'm not sure what "upset" is or could be though. Might be as simple as a lean code, or a rich code, or alternating between the two of them and still running OK...

Since my commute is typically open loop conditions, if it's "a little rich" all the time that it's in open loop, then it's going to be "a little rich" most of the time I drive it...

These concerns are why I see MAF as being more or less required. The system will add fuel to match the actual, measured, amount of air going into the engine. And I

think mix-and-matching parts can probably get me there.

To add to what Mark noted, see this link for the rest of the images:

http://therangerstation.com/forums/showthread.php?t=175035&page=2

The pictures are not separated, but there are more than one, FWIW.

It is very, very too bad that the 88 Turbocoupe head is a twin plug head. The runners on that intake would very closely match the ports on the 2.0 head (eyeballing it). But, twin plug, so no giant coolant passage, and different bolt pattern.

Personally, I would not be so quick to condemn the boneyard engines. I would investigate a bit more. Sometimes the condition of the rest of the vehicle will indicate whether it had been taken care of or was running on smoke & mirrors.

It seems it would be worth toting a battery & jumper cables, along with a compression tester and spark plug wrench, and checking the compression on those that appeared to not be covered head to toe with oil and grunge. Pulling the dipstick, looking at the oil, inspecting the top of the dipstick for evidence of former condensation, and the odor tell a lot. Putting a drop of oil on a white napkin/paper towel and letting it 'wick' will tell you how dirty the oil actually is. As the oil spreads, the entrained junk will leave a stain.

The ones that are discarded may just have A4LD transmissions (overdrive) that were just too much moolah to put into an old truck, the engine being fine. The Lima will go 300k miles(not kilometers, that would be about 483,000km) if tended to reasonably. It takes a lot of abuse to make one bad.

If you really could have gotten a turbo-bird, that would have bolted in nicely, but I guess the RCMP would be on your tailgate. (but they might not be able to catch you?)

tom

I've done things like checking dipsticks, but the oil is drained (via hole punched in the pan, no less), and typically the dipstick is dry by the time I get my hands on them. There's a 93 2.3 that I looked at, but the coolant reservoir looks like coffee and rad cap looks brown and crusty. OTOH, the oil cap looked absolutely perfect, no milkshake.

Pulling an engine, transporting it across the border, then trying to investigate if it's any good at home is a big pain (or I perceive it to be one anyway). 45 days to exchange it if it's "bad" is reasonable and generous given the pricing, but it also puts a rush on the project. Plus, it's very annoying that the only vehicle I have which can reasonably transport an engine is the same vehicle the engine has to go in. If everything seems to check out on an engine stand, then I throw it in the truck and find out it has rod knock, I have to un-swap the engine (and un-swap the EFI fuel sender, and un-swap the fuel lines, and drain the coolant, and all that) to be able to take the engine back. Big frustration.

My preference for a full engine swap is to buy a whole donor vehicle where I can see it running. But I'm not paying more than $500 for said vehicle, so the chances of that happening are slim. I'm only considering the "can't see it running" test dyno engine on the basis that it should be in excellent condition.

Most of the junked trucks I see have no body damage, and manual trans. Hard to say why they end up there. If there were an easy way to check how worn a clutch is, that would be wonderful. But I also try to avoid being underneath junkyard cars any longer than I have to be.