Bionicjoe

Member

- Joined

- Feb 1, 2022

- Messages

- 10

- Reaction score

- 2

- Location

- Nicholasville, KY

- Vehicle Year

- 2003

- Make / Model

- F250 SuperDuty

- Transmission

- Automatic

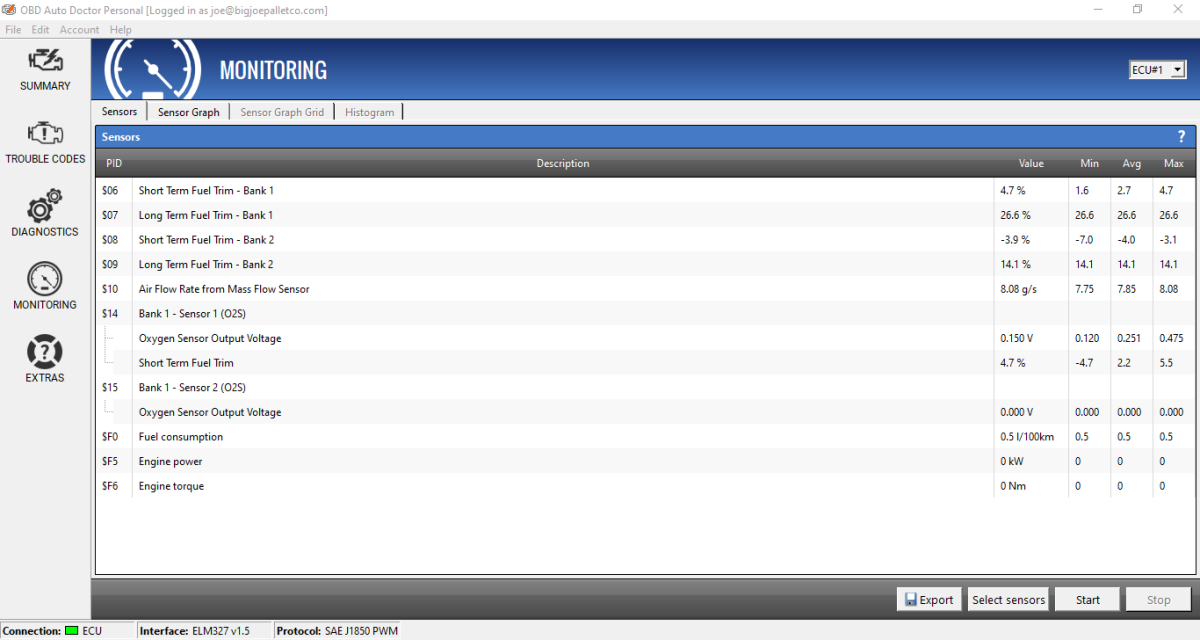

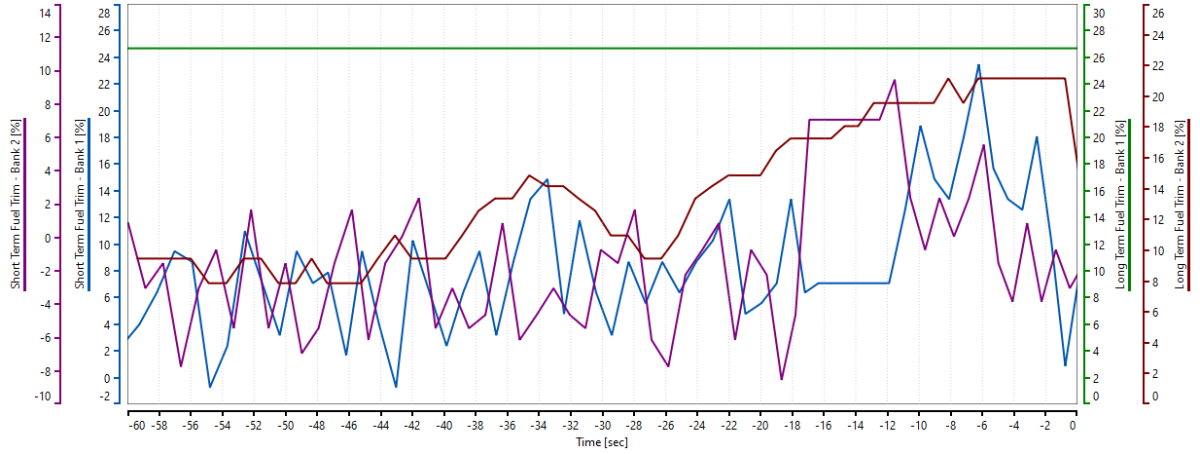

I've got an O2 sensor that is throwing codes and causing misfires. P0171 and all the misfires are on odd numbered cylinders. Fuel trim just sets at 26.6% on the long term fuel trim. I cleared the data and drove around while watching the OBD data. Goes right to 26.6

Spark plugs were replaced 6 months ago and it ran perfect until I did some front end work and repaired a brake line. Had to remove the air intake. So maybe a wire got broken. There are no voltage numbers on this sensor.

Where do I find Bank 1-Sensor 2? All the videos I find just show the sensor on the exhaust.

Also I took it to the mechanic and they replaced an O2 sensor (my request) and verified there were no vacuum leaks.

Spark plugs were replaced 6 months ago and it ran perfect until I did some front end work and repaired a brake line. Had to remove the air intake. So maybe a wire got broken. There are no voltage numbers on this sensor.

Where do I find Bank 1-Sensor 2? All the videos I find just show the sensor on the exhaust.

Also I took it to the mechanic and they replaced an O2 sensor (my request) and verified there were no vacuum leaks.