mxl4729

New Member

- Joined

- Dec 21, 2021

- Messages

- 11

- Reaction score

- 7

- Points

- 3

- Location

- churchville MD

- Vehicle Year

- 2008

- Make / Model

- ford ranger

- Transmission

- Automatic

i bought a 2008 ford ranger 3.0 with 90K miles a few years ago.

the truck ran ok but seems to run a little rough at idle and lacks power but that my just be because it has the 3.0

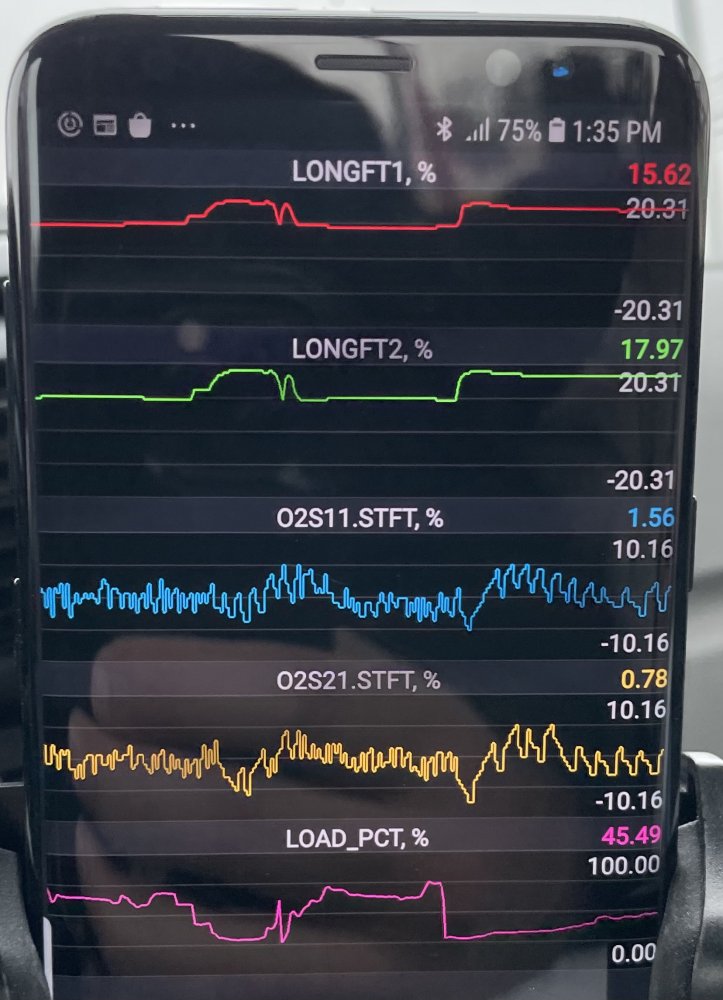

well when running the code scanner the long term fuel trim in bank 1 and 2 are high at idle. Bank 1 is around 15.6% and bank two is 17.9%

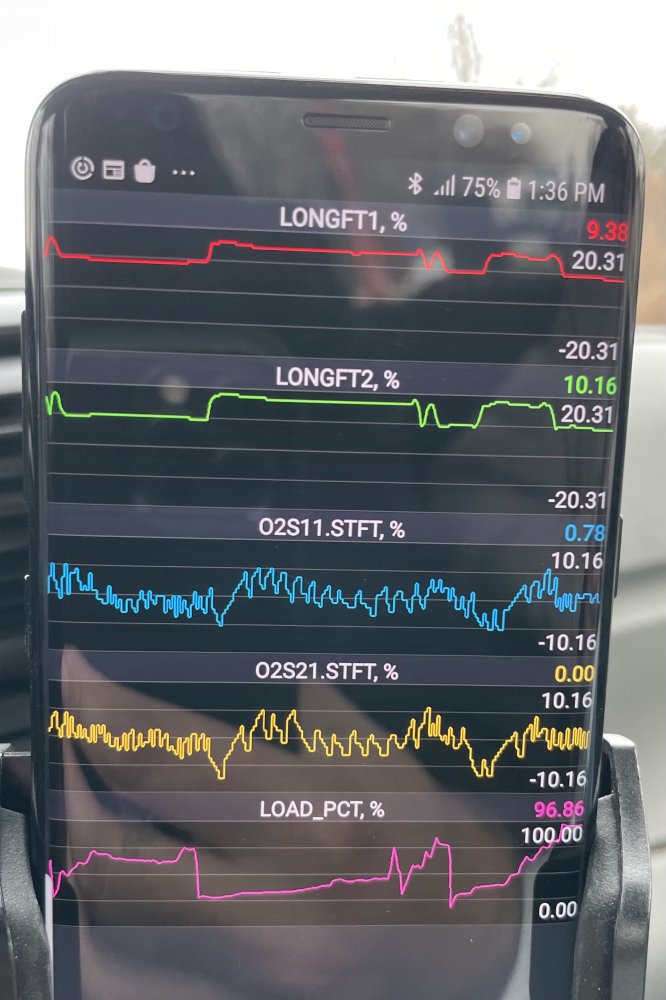

when the truck is under load close to flooring it 96% load the long term fuel trim drops to around bank 1 9.3% and bank 2 10.1%

short term fuel trims seem to hover around 0 like it should all the time.

these high long term fuel trims made me thing i had a vacuum leak and or bad MAFS. I cleaned the MAFS and then replaced it with no change in LTFT. next i did a smoke test and the only place i had any smoke was the EGR valve. i replaced it and the new one seems to smoke the same amount so i don't think that's the source of my leak.

I checked my fuel pressure that that seemed good as well. I am kind of stumped. i would think under load at high RPM the LTFT would drop more then 7% or so but i don't know what it should be doing.

Based on the attached graph and the info above would you agree i have a small vacuum leak?

anyone have any ideas that i should be checking on the 3.0?

image below is no load at idle

Image below is almost full load

,,,

,,,

the truck ran ok but seems to run a little rough at idle and lacks power but that my just be because it has the 3.0

well when running the code scanner the long term fuel trim in bank 1 and 2 are high at idle. Bank 1 is around 15.6% and bank two is 17.9%

when the truck is under load close to flooring it 96% load the long term fuel trim drops to around bank 1 9.3% and bank 2 10.1%

short term fuel trims seem to hover around 0 like it should all the time.

these high long term fuel trims made me thing i had a vacuum leak and or bad MAFS. I cleaned the MAFS and then replaced it with no change in LTFT. next i did a smoke test and the only place i had any smoke was the EGR valve. i replaced it and the new one seems to smoke the same amount so i don't think that's the source of my leak.

I checked my fuel pressure that that seemed good as well. I am kind of stumped. i would think under load at high RPM the LTFT would drop more then 7% or so but i don't know what it should be doing.

Based on the attached graph and the info above would you agree i have a small vacuum leak?

anyone have any ideas that i should be checking on the 3.0?

image below is no load at idle

Image below is almost full load