FliesLikeABrick

New Member

- Joined

- May 12, 2021

- Messages

- 11

- Reaction score

- 19

- Points

- 3

- Location

- Virginia, US

- Vehicle Year

- 1995

- Make / Model

- Ford Ranger

- Transmission

- Manual

1998 Ranger with utility outfit, with a 4R44E transmission.

While working on it, I noticed that the reverse lights were not coming on. Makes sense, everything else between the operator and the transmission was worn out because it was a oft-driven, short-tripped plant truck. 100k miles, many of which were probably driven on the ~500 acres property.

I looked at the wiring diagram and saw that it is just a circuit closed by the "transmission range sensor" on the side of the transmission, which wraps around the shift linkage/input.

I tested by backprobing and frontprobing the connectors, everything seemed fine but the module was not closing the circuit

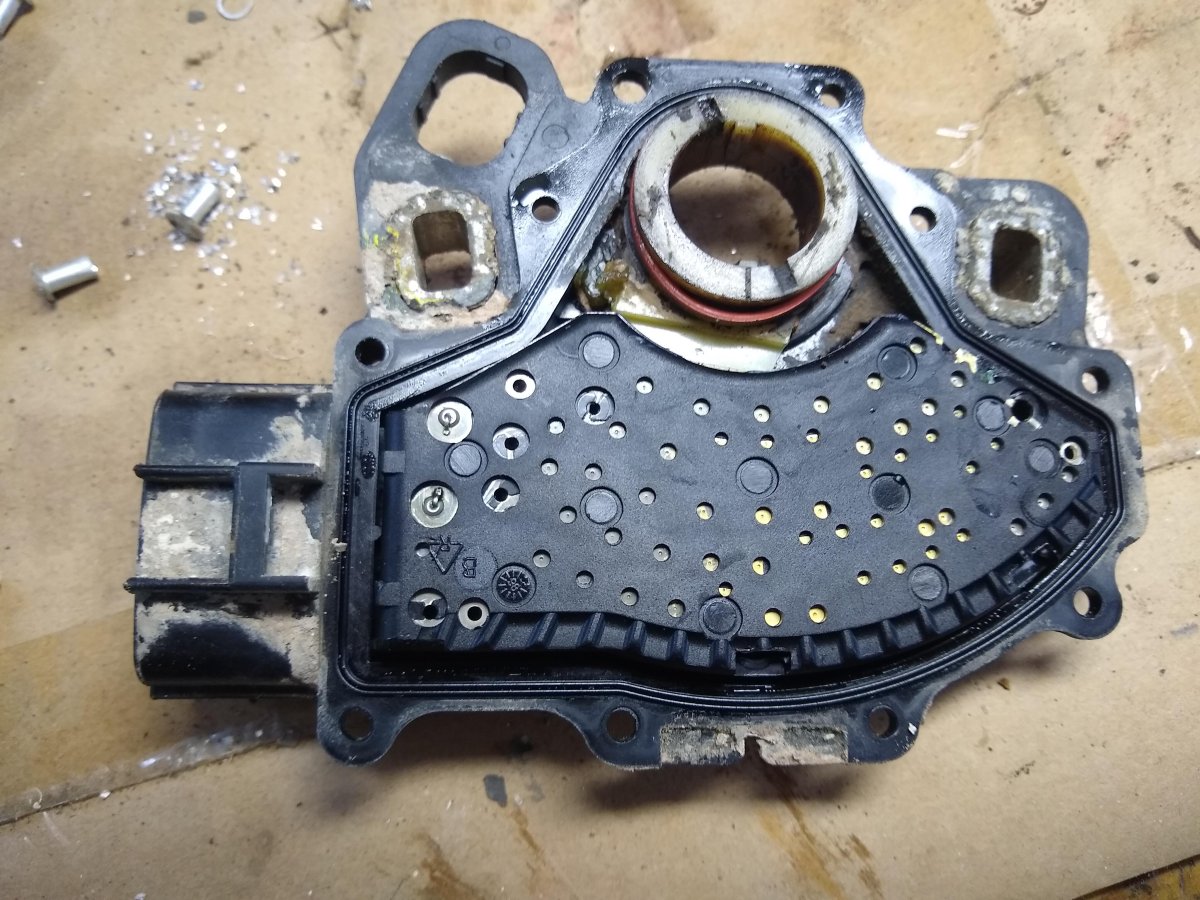

Liberated and on the bench. Figured if this thing is pooched, let's open it up and see if it can be fixed. Worst case it stays broken and I order a replacement anyway, best case it gets fixed faster and cheaper

drilled out the rivets:

Met with an intermediate cover that has the upper traces for the upper set of contacts

Under that is the arm with one type of contacts on it

Then on the bottom of that is another type of contact which closes multiple traces together. One of these springloaded contacts had fallen out and was in the corner of the housing

The spring shown on the left below was damaged and couldn't be reused. I took a sprint from a ballpoint pen and cut it down shorter to use it.

Also the contact kept wanting to pop out because its retention features were worn away, so I drilled a small hole through the plastic arm and pushed in 2 pieces of steel wire (actually from a paperboard chinese takeout container "bail", bent into a u-shape), which went through the existing holes in the contact to retain it.

Pop-riveted it back together, reinstalled under the truck -- that was 20,000 miles ago (sold this truck to my brother) and it's worked perfectly.

I also replaced the orange o-rings/seals on the contact arm, since they seemed slightly swollen/elongated and didn't want to go together nicely. I just replaced them with the nearest size from one of the usual nitrile o-ring assortment sets.

Thanks for reading. I think the lesson here is ... if it's already broke, might as well try to fix it before replacing it. Worst case you learn something and still replace it, best case you learn something and come out ahead with a faster and cheaper fix.

While working on it, I noticed that the reverse lights were not coming on. Makes sense, everything else between the operator and the transmission was worn out because it was a oft-driven, short-tripped plant truck. 100k miles, many of which were probably driven on the ~500 acres property.

I looked at the wiring diagram and saw that it is just a circuit closed by the "transmission range sensor" on the side of the transmission, which wraps around the shift linkage/input.

I tested by backprobing and frontprobing the connectors, everything seemed fine but the module was not closing the circuit

Liberated and on the bench. Figured if this thing is pooched, let's open it up and see if it can be fixed. Worst case it stays broken and I order a replacement anyway, best case it gets fixed faster and cheaper

drilled out the rivets:

Met with an intermediate cover that has the upper traces for the upper set of contacts

Under that is the arm with one type of contacts on it

Then on the bottom of that is another type of contact which closes multiple traces together. One of these springloaded contacts had fallen out and was in the corner of the housing

The spring shown on the left below was damaged and couldn't be reused. I took a sprint from a ballpoint pen and cut it down shorter to use it.

Also the contact kept wanting to pop out because its retention features were worn away, so I drilled a small hole through the plastic arm and pushed in 2 pieces of steel wire (actually from a paperboard chinese takeout container "bail", bent into a u-shape), which went through the existing holes in the contact to retain it.

Pop-riveted it back together, reinstalled under the truck -- that was 20,000 miles ago (sold this truck to my brother) and it's worked perfectly.

I also replaced the orange o-rings/seals on the contact arm, since they seemed slightly swollen/elongated and didn't want to go together nicely. I just replaced them with the nearest size from one of the usual nitrile o-ring assortment sets.

Thanks for reading. I think the lesson here is ... if it's already broke, might as well try to fix it before replacing it. Worst case you learn something and still replace it, best case you learn something and come out ahead with a faster and cheaper fix.

Attachments

-

168.9 KB Views: 21

-

201.2 KB Views: 18