lowspeedpursuit

Well-Known Member

Okay, so the TL;DR is I screwed myself over*, and now I get to rebuild my transmission more carefully a second time.

First question: I have a couple of chipped corners on the input shaft gear after removing the bearing. I'm leaning towards replacing it, but I wanted to double-check if that's necessary, because it'll delay reassembly for two weeks. Forgive the picture quality, USPS has decided they have "no access to my property" to deliver my new phone.

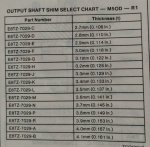

Second question: My original input bearing shim is part J (.129). I also have an input bearing shim kit with a .112 base, 3x .005, and 3x .010. Obviously this affords me different combinations than the other factory shims, which are available in increments of .004. I've read on here that rather than being comfortable anywhere in the manual's play spec range of .002-.006, it's better to target .002 specifically. How true/important is this?

Basically, if I end up being able to build play to, say, .004 with what I have, is it actually worth it to go out of my way to source a Ford shim that could bring me down to .002 instead?

Third question: Are there any other gotchas about this rebuild? I'm assuming excessive ISB play is my continuing problem, but I do not want to take this thing apart a third time.

Thanks in advance.

-----

*I take like 90% of the blame on this, but I give some to USA Standard Gear, whose "full rebuild kit" includes neither new stake nuts nor input shaft bearing shims. I measured ISB play of ~.014 and could only come up with a .006 shim in a workable size. So, I ran it even though that's slightly above spec, figuring I needed the truck, and it had to run better than when I inherited the trans. Apparently I was wrong.

-----

EDIT: Input shaft is ordered, since it seemed silly just to wait around. Still curious if the chips on the old shaft are dealbreakers. Measured play in the 3rd-gear bearing snap ring somewhere between .002-.0025 vs. a spec of 0-.0019, so part D there is getting replaced with E8TZ-7030-E, which is .002 thicker. Will update as parts come in.

First question: I have a couple of chipped corners on the input shaft gear after removing the bearing. I'm leaning towards replacing it, but I wanted to double-check if that's necessary, because it'll delay reassembly for two weeks. Forgive the picture quality, USPS has decided they have "no access to my property" to deliver my new phone.

Second question: My original input bearing shim is part J (.129). I also have an input bearing shim kit with a .112 base, 3x .005, and 3x .010. Obviously this affords me different combinations than the other factory shims, which are available in increments of .004. I've read on here that rather than being comfortable anywhere in the manual's play spec range of .002-.006, it's better to target .002 specifically. How true/important is this?

Basically, if I end up being able to build play to, say, .004 with what I have, is it actually worth it to go out of my way to source a Ford shim that could bring me down to .002 instead?

Third question: Are there any other gotchas about this rebuild? I'm assuming excessive ISB play is my continuing problem, but I do not want to take this thing apart a third time.

Thanks in advance.

-----

*I take like 90% of the blame on this, but I give some to USA Standard Gear, whose "full rebuild kit" includes neither new stake nuts nor input shaft bearing shims. I measured ISB play of ~.014 and could only come up with a .006 shim in a workable size. So, I ran it even though that's slightly above spec, figuring I needed the truck, and it had to run better than when I inherited the trans. Apparently I was wrong.

-----

EDIT: Input shaft is ordered, since it seemed silly just to wait around. Still curious if the chips on the old shaft are dealbreakers. Measured play in the 3rd-gear bearing snap ring somewhere between .002-.0025 vs. a spec of 0-.0019, so part D there is getting replaced with E8TZ-7030-E, which is .002 thicker. Will update as parts come in.

Last edited: