I got the Valve body swapped out today and changed the fluids in the transfer case and differential. Seems the transfer case is a D2562.

The valve body wasn't so bad, just kinda messy, and I couldn't possibly catch it all. Got a large bottle of Dawn detergent to soak the gravel with(maybe it'll help to dissolve some of it).

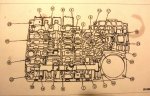

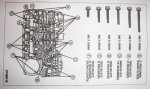

The gasket material worked well enough to hold the bolts, but it was difficult to match them up with their prospective slots as I had to transfer from a view above to a flipped one on the ground, but going back together I only had two (X2) I had to switch(one too long, one too short, switch kinda deal).

I also really messed up with the reverse servo gasket, but hadn't even known it existed until seeing it leaned up in the drain pan. I followed the pattern visible on the old valve body and placed the gasket in place on the new valve body, started all the bolts in with a cordless drill, clutch adjusted on 1(of 1-24) and ran em in using the torque sequence. Then set em on in with the in-lb torque wrench(loaner from AZ, still in the cellophane, about $50 I think).

Then a lightbulb came on :/ as I realized I'd put the reverse servo cover gasket on the rong side of the valve body, and only choice was to drop it, and move the gasket, and so I did.

Only back the bolts out( every one) and wiggled it loose enough to drop free of the transmission enough, fished a needle nose pliers around a crossmember and some other stuff and fished it out from behind, then started back in with the cordless screwdriver and then torque wrench, each in sequence to 85 in-lb( a number I calculated as just above midway of the high and low side of the torque recommendation.

Then the reverse servo w/ its' gasket under the cover, and on to the pan and dropping the fluids in the TC and Diff.

I was filling them all as the daylight rapidly began to wane, had enough fluids all around, excepting had to use some Dexron V in the TC.

After filling the transmission started the engine and just let it idle a while, then put it into R and let the tires idle around a bit, then into D, still idling. Then shut it off and let the fluid settle as I filled the TC and Diff. fluid.

Then re-checked the transmission and it was showing about a qt high. Took it off the jacks as the last vestule of daylight flickered away, a misty rain had begun to fall.

Then I drove it 50 miles, filled the tank, my last one computed as just over 10 mpg(14 gal to go 150 miles) but the engine seems to be a bit smoother although it still has definite issues (sputters under any strain, and still has codes) I picked these codes up after it sat about an hour P0401, P0756, and another P0104.

The transmission is doing better w/ reverse, doesn't seem to grind as before under strain, but still does it on the highway going into a heavy wind, although it didn't coming back w a tailwind.