- Joined

- Aug 15, 2007

- Messages

- 1,613

- Reaction score

- 46

- Points

- 48

- Location

- toenails of foothills NW of Atlanta

- Vehicle Year

- 1985

- Make / Model

- ford

- Engine Type

- 2.3 (4 Cylinder)

- Engine Size

- lima bean

- Transmission

- Manual

- 2WD / 4WD

- 2WD

- My credo

- vertical and above ground

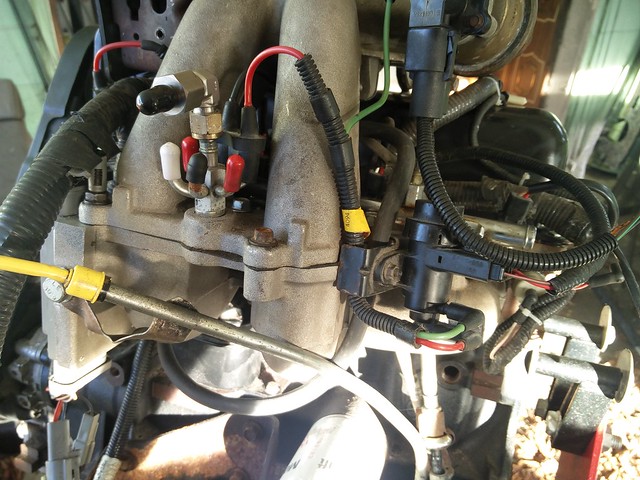

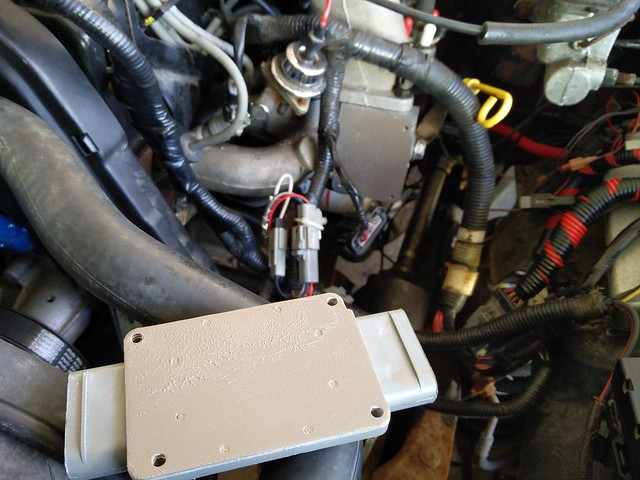

I think I saw the computer sitting right next to the brake reservoir. Where do you plan on mounting it? I would think you'd want it inside the cab unless you can build a weatherproof box. It's not the computer I'd worry about, it is all the wires on the huge connector. I don't think that vintage was weatherized at all, depending on the shelter of the cab to keep it from corrosion. I figure you had it out in the engine bay for testing...

So you found the BOBO switch connector? I think it was plumbed for the install of cruise control... Kill the cruise with a touch of the brake pedal. Maybe not. If you had an EEC-IV, one of the diagnostic tests, key on engine off(IIRC) was the signal to twist the steering wheel, stomp on the brake pedal, and floor the throttle. Hmm, maybe I have mixed the two, but those three things were tests. One for the BOBO, one for the WOT, and one for the PSPS - power steering pressure switch, needed assist at idle when parking to overcome pump load. If you did not do the appropriate things, you'd set a code or get a blinky indicating there was a problem with one/more of those inputs. FWIW. I'm sure you wanted to know that tidbit. For some reason I had in my mind that the BOBO was the BOOB switch... at least I recognized my error.

tom

So you found the BOBO switch connector? I think it was plumbed for the install of cruise control... Kill the cruise with a touch of the brake pedal. Maybe not. If you had an EEC-IV, one of the diagnostic tests, key on engine off(IIRC) was the signal to twist the steering wheel, stomp on the brake pedal, and floor the throttle. Hmm, maybe I have mixed the two, but those three things were tests. One for the BOBO, one for the WOT, and one for the PSPS - power steering pressure switch, needed assist at idle when parking to overcome pump load. If you did not do the appropriate things, you'd set a code or get a blinky indicating there was a problem with one/more of those inputs. FWIW. I'm sure you wanted to know that tidbit. For some reason I had in my mind that the BOBO was the BOOB switch... at least I recognized my error.

tom