94' Ranger

Member

- Joined

- Jan 17, 2021

- Messages

- 36

- Reaction score

- 17

- Points

- 8

- Location

- Southern California

- Vehicle Year

- 1994

- Make / Model

- Ford Ranger

- Engine Type

- 3.0 V6

- Transmission

- Manual

- 2WD / 4WD

- 2WD

- Tire Size

- 15in rims + Falken AT3

Last week I started working on my 94' 3.0 Ranger, I wanted to replace everything included in the head gasket set and replace anything along the way that wanted replacing. I brought my heads to a reputable machine shop (had one small crack on intake) and a few days later my heads were back on. This was my first head gasket job, however I did have an experienced mechanic working with me.

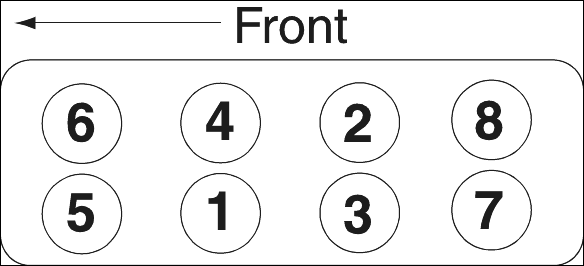

I used a torque wrench and carefully tightened my heads to these specs in this order:

1st: 59ft/lb

2: Loosen all bolts one turn

3: 35ft/lb

4: 66ft/lb

All rocker arm bolts were tightened to 8ft/lb, then to 24ft/lb. I needed to rotate the crankshaft in order to tighten the rocker arms as per instructed. I never touched my lifters or loosened any lifter guides.

Well, I started her in the garage around midnight after about a week of working on the truck, and the idle sounded amazing once I perfected the timing. I added coolant as needed for about 10 minutes, then left her to idle in the garage for about 30 minutes. I checked the oil in the dipstick, looked clean and clear.

At that point I decided it was safe to take her for a very gentle test drive. I drove about 10 minutes to the nearest car wash and noticed nothing strange at this point. As I left the car wash I noticed the truck was running a bit hotter than usual, about halfway on the temp gauge. On my way back home the engine began to run worse and worse and the temp gauge was up to about 3/4ths. I coasted as much as possible on the way home because at this point I heard weird noises and the engine began to run badly. I pulled back into my driveway and my truck idled like hell till it gradually stalled out.

The next morning I checked the dipstick to find a creamy milkshake in my oil pan...

I pulled my heads and lower intake back off again, got my heads checked for compression and warpage, thankfully those were undamaged. All head bolts took the same amount of torque to break them free, none were notably loose. I also noted that the head gasket for cylinders 123 left about half of the gasket on my block upon removal while the head gasket for cylinder 456 only left about 10% of its material stuck to the block. Besides that there were no obvious failure points or major differences between the left and right head gaskets.

Upon pulling my lower intake I found that my lifter guides (aka tappet guides) on cylinders 456 were all broken.

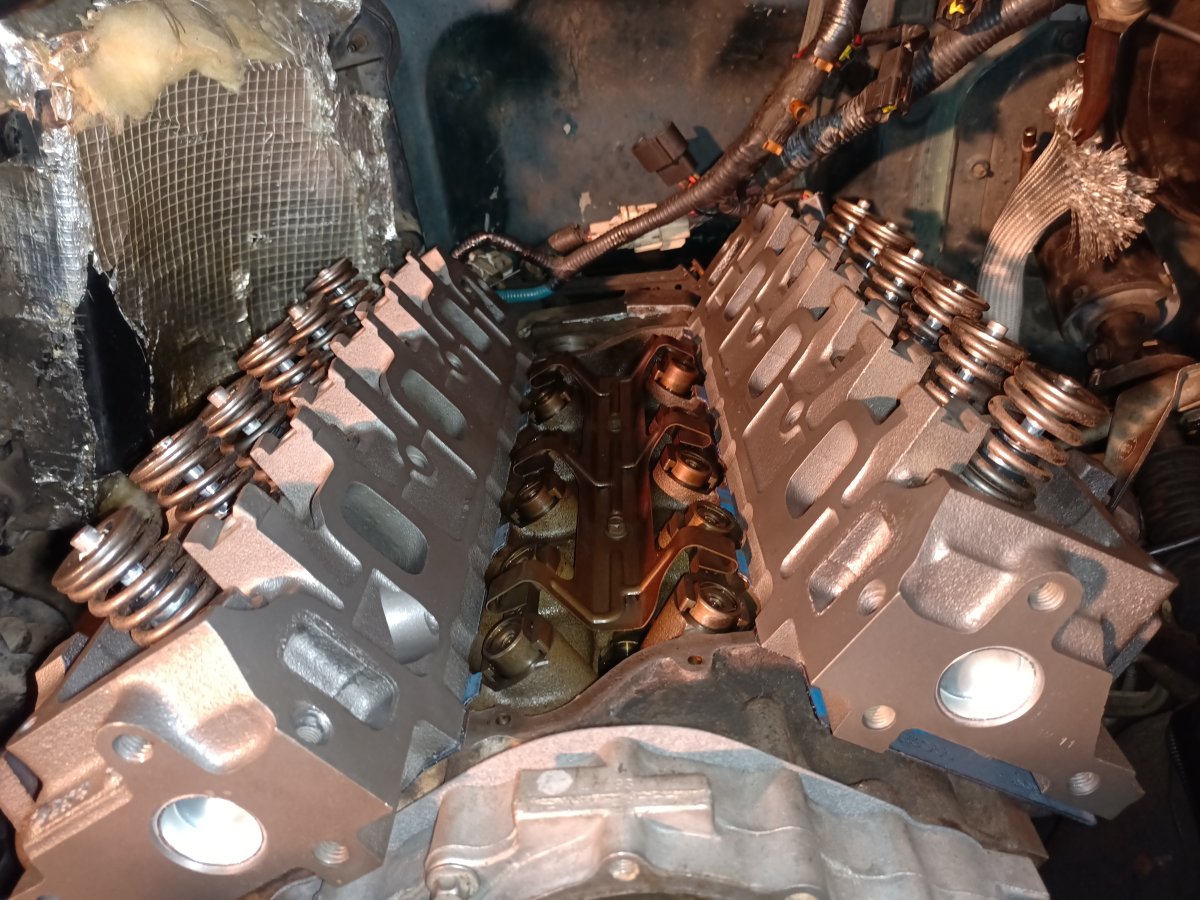

I pulled the keeper plate to find that the lifters on 456 were severely damaged. The lifters on cylinders 123 were barely damaged, possibly from the metal debris flying off the lifters from cylinders 456.

Below is a picture of my lifters from cylinders 456.

Now finally, some good news.

I was able to find a 1994 3.0 Ford Aerostar at a local junkyard and after a couple hours of work, I was able to pull all of the rockers, pushrods, lifters, and guides out and bought them all for 63$. Soaked them in gasoline overnight.

So now it's time to put it all back together (after I pull the oil pan AGAIN to remove the debris) but I do not know what to do differently because I don't know what caused my problem in the first place.

From the last few days of research and asking mechanics, I'm beginning to be convinced that what caused this failure is a case of hydro lock due to either head gasket failure or lower intake gasket failure on cylinders 456. Coolant gets sucked into cylinders, water doesn't like to compress, and so either my engine must stop or a mechanical failure must occur.

However, I refuse to reassemble my engine again the same way I did before and expect a different result, even though I meticulously followed all directions and torque specs (I work as a service writer at an auto shop, I was able to print out detailed cylinder head removal instructions for my vehicle).

Can anyone here think of a single other possibility that could cause the damage I am seeing? Remember, it idled perfectly in my garage for over 30 minutes without sucking up coolant or mixing the oil with coolant. It has damage that is almost entirely isolated to one head and the problem did not occur until after it was driven.

I am NOT trying to go for take #3 on this job, if anyone has any advice or an idea about what might have caused my issue and how to prevent it from happening again, I'd really appreciate it.

It is imperative that I don't spend another week and more money on new gaskets and head bolts.

Please advise, cheers.

I used a torque wrench and carefully tightened my heads to these specs in this order:

1st: 59ft/lb

2: Loosen all bolts one turn

3: 35ft/lb

4: 66ft/lb

All rocker arm bolts were tightened to 8ft/lb, then to 24ft/lb. I needed to rotate the crankshaft in order to tighten the rocker arms as per instructed. I never touched my lifters or loosened any lifter guides.

Well, I started her in the garage around midnight after about a week of working on the truck, and the idle sounded amazing once I perfected the timing. I added coolant as needed for about 10 minutes, then left her to idle in the garage for about 30 minutes. I checked the oil in the dipstick, looked clean and clear.

At that point I decided it was safe to take her for a very gentle test drive. I drove about 10 minutes to the nearest car wash and noticed nothing strange at this point. As I left the car wash I noticed the truck was running a bit hotter than usual, about halfway on the temp gauge. On my way back home the engine began to run worse and worse and the temp gauge was up to about 3/4ths. I coasted as much as possible on the way home because at this point I heard weird noises and the engine began to run badly. I pulled back into my driveway and my truck idled like hell till it gradually stalled out.

The next morning I checked the dipstick to find a creamy milkshake in my oil pan...

I pulled my heads and lower intake back off again, got my heads checked for compression and warpage, thankfully those were undamaged. All head bolts took the same amount of torque to break them free, none were notably loose. I also noted that the head gasket for cylinders 123 left about half of the gasket on my block upon removal while the head gasket for cylinder 456 only left about 10% of its material stuck to the block. Besides that there were no obvious failure points or major differences between the left and right head gaskets.

Upon pulling my lower intake I found that my lifter guides (aka tappet guides) on cylinders 456 were all broken.

I pulled the keeper plate to find that the lifters on 456 were severely damaged. The lifters on cylinders 123 were barely damaged, possibly from the metal debris flying off the lifters from cylinders 456.

Below is a picture of my lifters from cylinders 456.

Now finally, some good news.

I was able to find a 1994 3.0 Ford Aerostar at a local junkyard and after a couple hours of work, I was able to pull all of the rockers, pushrods, lifters, and guides out and bought them all for 63$. Soaked them in gasoline overnight.

So now it's time to put it all back together (after I pull the oil pan AGAIN to remove the debris) but I do not know what to do differently because I don't know what caused my problem in the first place.

From the last few days of research and asking mechanics, I'm beginning to be convinced that what caused this failure is a case of hydro lock due to either head gasket failure or lower intake gasket failure on cylinders 456. Coolant gets sucked into cylinders, water doesn't like to compress, and so either my engine must stop or a mechanical failure must occur.

However, I refuse to reassemble my engine again the same way I did before and expect a different result, even though I meticulously followed all directions and torque specs (I work as a service writer at an auto shop, I was able to print out detailed cylinder head removal instructions for my vehicle).

Can anyone here think of a single other possibility that could cause the damage I am seeing? Remember, it idled perfectly in my garage for over 30 minutes without sucking up coolant or mixing the oil with coolant. It has damage that is almost entirely isolated to one head and the problem did not occur until after it was driven.

I am NOT trying to go for take #3 on this job, if anyone has any advice or an idea about what might have caused my issue and how to prevent it from happening again, I'd really appreciate it.

It is imperative that I don't spend another week and more money on new gaskets and head bolts.

Please advise, cheers.

Last edited: