youngbuckwithapickuptruck

Well-Known Member

- Joined

- Oct 7, 2021

- Messages

- 124

- City

- california

- Vehicle Year

- 00

- Engine

- 2.5 (4 Cylinder)

- Transmission

- Manual

- Tire Size

- stock

i have check engine light code on: p0171 bank 1 running lean

i tried the cigar smoke test twice, no smoke

i tried propane spray test no results

then i was told use carb cleaner cause it is way more volatile and i will be able to hear the idle change easier.

soooo.... i know this can catch my car on fire.

1. dont spray on an area so long that fluid pools up, then heats up and then ignites

2. run the test on a cold engine

3. keep a fire extinguisher handy,

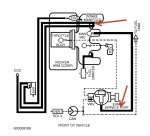

4. i cant find any vacuum diagrams and am having trouble identifying where exactly are all my vacuum lines, halp???

5. also i imagine the leaks are most likely to be at the connection ends of each vacuum line, ya?

6. im reading that some vacuum lines connect to the brake system. is this the case with 2000 ranger?

any other tips, please?

i asked a shop if they would do a vacuum leak test and they said they could only do a check engine light diagnostic which would be $160 or more, depending on how long it took. i suppose i could also ask the ghetto shop down the road how much for a vacuum leak test.

i tried the cigar smoke test twice, no smoke

i tried propane spray test no results

then i was told use carb cleaner cause it is way more volatile and i will be able to hear the idle change easier.

soooo.... i know this can catch my car on fire.

1. dont spray on an area so long that fluid pools up, then heats up and then ignites

2. run the test on a cold engine

3. keep a fire extinguisher handy,

4. i cant find any vacuum diagrams and am having trouble identifying where exactly are all my vacuum lines, halp???

5. also i imagine the leaks are most likely to be at the connection ends of each vacuum line, ya?

6. im reading that some vacuum lines connect to the brake system. is this the case with 2000 ranger?

any other tips, please?

i asked a shop if they would do a vacuum leak test and they said they could only do a check engine light diagnostic which would be $160 or more, depending on how long it took. i suppose i could also ask the ghetto shop down the road how much for a vacuum leak test.

Last edited: