Uncle Gump

Boomers gotta Boom

TRS Event Staff

TRS Forum Moderator

Supporting Member

VAGABOND

TRS Event Participant

GMRS Radio License

TRS 25th Anniversary

- Joined

- Sep 17, 2018

- Messages

- 16,091

- City

- Ottawa IL

- State - Country

- IL - USA

- Vehicle Year

- 1986

- Vehicle

- Ford Bronco II

- Drive

- 4WD

- Engine

- 2.9 V6

- Transmission

- Manual

- My credo

- Lead follow or get out of my way

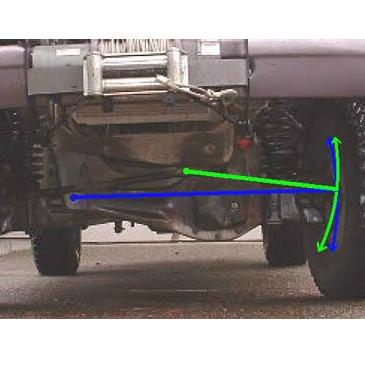

I try to find a helper to sit in the truck and work the steering wheel while it's running and the weight is on the front end... I inspect all the moving parts from below. It makes looseness anywhere pretty visible.

As shot as those tires are and the apparent alignment issues... It doesn't surprise me a bit you can't keep it in it's lane.

As shot as those tires are and the apparent alignment issues... It doesn't surprise me a bit you can't keep it in it's lane.