NOTE: Jolene_The_Ranger did a 1993 4.0 OHV to 1999 4.0 SOHC swap on his 1993 Ford Ranger. See his BUILD THREAD HERE.

1993 4.0 OHV To 1999 4.0 SOHC:

Swapping a 4.0 SOHC engine into a OBD1 or OBD2 Ford Ranger that has a 4.0 OHV engine. This swap uses the OBD1 OR OBD2 OHV engine wire harness, computer, and body harness.

What’s The Difference?

Almost double the horsepower and 50 foot-pounds of torque at the wheels. (Note: The 4.0 OHV is rated at 160 horsepower from the factory and the 4.0 SOHC is rated at 207 horsepower)

I had my computer tuned to help run the SOHC as best as possible, and before any adjustments were made, we made note that the SOHC is completely safe to run on an old OBD1 or OBD2 OHV computer with a stock tune.

It’s a little fat on the top end but doesn’t lean out anywhere.

SOHC power output (at the wheels) on original the OHV tune was 165HP, 180TQ. (OHV power on same computer and in the same truck was 100 HP/139TQ)

After a tune the SOHC put out 179HP/185TQ in a ranger with a C4 automatic transmission, 35-inch tires, and 5.13 gears.

Mounting The Engine:

1. Trucks with heater boxes still in will need clearance on the box for the passenger side valve cover.

2. Engine mounts:

The stock 4.0 OHV engine mounts will work on a 2wd but will need to be shimmed up on 4×4 frames. This can be done with a plate or washers in between the frame and the bracket.

Autofab 4.0 OHV engine mounts will also work and do not need to be shimmed.

3. The transmission bell housing is the same aside from one of the top bolts.

4. The SOHC engine itself is a bit taller than the OHV, so if you have a cross tube on an engine cage, you’ll want to watch for clearance issues.

Accessories:

1. Power steering pump.

The OHV steering pump will not work. You will need to get a SOHC steering pump. This is good because it’s WAY quieter.

Custom lines for the steering pump will need to be made because the pump is in a different location than the old one.

2. Alternator.

The OHV alternator WILL bolt to the SOHC minus one bolt. You can build a bracket to accommodate the other missing bolt or leave it with 2 bolts. Pulley location is perfect.

NOTE: You have to use the ohv alternator because of wiring.

3 Air conditioning: N/A for my application.

Fuel Delivery:

Your OBD1 ranger has a return style fuel rail. In order to use your existing fuel system for the SOHC you will need one of two things:

1) Fuel rails from a 1997 Ford Explorer SOHC 4.0 (these are the only year SOHC return style fuel rails.

OR

2) New fuel pressure regulator that sends correct pressure to the fuel rail, and a return bypass back to the tank. (I went with the 1997 explorer fuel rails)

You will use the SOHC injectors.

Wiring:

Remember, you’re putting a OBD2 controlled engine into a OBD1 environment. No sensor from the SOHC will talk to the OBD1 computer.

Injector wiring will be the same polarities and plugs between the OHV and SOHC, so plug them in like normal.

Use the IAC off of the OHV. It uses the same mounting surface and bolt holes on the SOHC just in a different location.

Use the old crank position sensor off the OHV. It bolts to the front of the block the exact same way.

Throttle position sensor is the same between the two engines. Use either one.

Use your old OHV OBD1 MAF

The OHV has a separate AIT (air intake temp sensor) and the SOHC has it integrated with the MAF. You will need to make a mount for the old IAT.

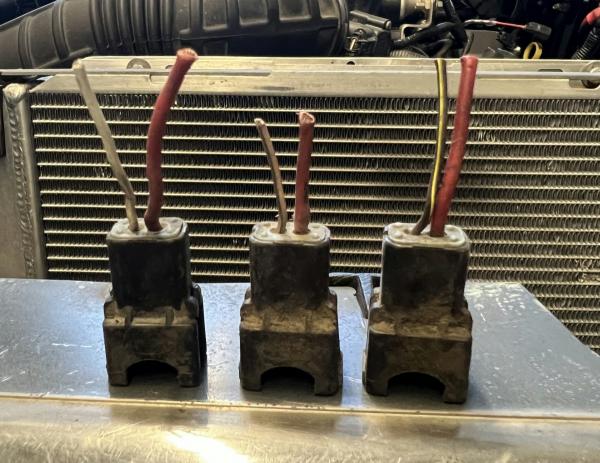

What I did was made a plug to block off the EGR port on the SOHC intake and tapped the plug with 1/4″ npt so the old AIT sensor threaded into the newly made plug (PIC BELOW)

Your OHV may or may not have a cam position sensor. This is the only sensor that will not transfer over. The SOHC has this sensor on the driver side valve cover. Leave it bolted in so it doesn’t leak, but no cam sensor will be used. the engine runs without it. On the OBD1 system this sensor is only used to measure knock.

Use the OHV alternator so that plugs in like normal

Temp sensors:

You have 2. Both are 3/8″ npt thread. On the SOHC thermostat housing there will be spaces for two sensors as well, but one is a smaller thread. Drill and tap it to accommodate your OHV sensors.

Oil pressure sensor is transferred from OHV to SOHC and uses the same thread pitch on the driver side of the block.

Ignition coil is exactly the same. Use either one.

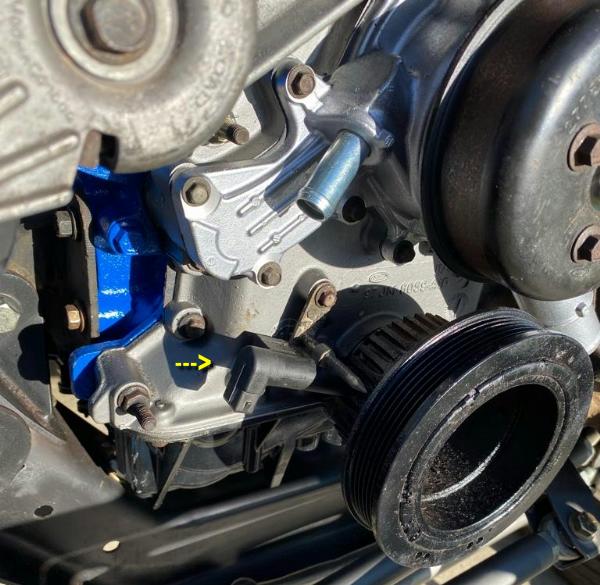

Old cps on new block:

Miscellaneous:

You’ll need to get a SOHC throttle cable. It mounts to the old gas pedal just fine.

Input From Our Members:

Snoranger: I built my EEC-IV SOHC about 10 years ago, I started off with no cam sync. It ran fine, but without the can signal it was batch fire. I ran it for about 6-8 months like that until I had an epiphany… make a cam sync. Take an oil pump drive plug from a SOHC. Take a cam sync from an OHV. Disassemble both of them. Cut the bottom of the synchronizer off. Machine both pieces so they can be pressed together. Press them together and weld it. Reassemble your new SOHC can synchronizer with the parts from the OHV cam sync. Drop it in, set it with the tool, plug in the sensor.

If you “just tune it out” (cam sync) The ECM won’t know if the cylinder it on the compression or exhaust stroke. That’s fine for the wasted spark system, it fires at both times anyway. But how will it know when to fire the injector? It will have to batch fire the injectors.

Another thing you have to watch out for. The OHV and SOHC crank sensors use the same connector, but the wires are reversed. (Depending on the year.) When it’s all installed, if you have no spark… de-pin the crank sensor plug and swap the wires.

Miscellaneous Photos:

Click to enlarge.

1992 4.0 OHV to 2007 4.0 SOHC:

Alright I’m halfway through this swap and running into some roadblocks I hope someone will be able to assist me with. Here’s what I’m working with.

SOHC 4.0 out of a 2007 Ford Ranger. My original OHV was out of a 1992 Ford Explorer. My SOHC appears to have a completely different intake manifold than the one Jolene has (above). That’s where I’m running into some issues.

When attempting to bolt the OHV IAC onto the SOHC there is a clearance issue. I can fabricate a plate to raise it up enough to bolt on as long as that won’t cause an issue.

I ended up swapping over to the SOHC IAC and it seems to be working fine. I just swapped the plug to my old harness.

Second is the Crank Position Sensor (CPS). I bolted the OHV unit onto the new motor and there’s a clearance issue there as well. The prong that sticks out is rubbing into the crank pulley. I believe that metal prong that’s sticking out is just used as a reference point when using a timing light. in which case I could cut it down to clear the harmonic balancer. My OHV balancer is the same size as the SOHC so swapping over wouldn’t do me any good.

For some reason my OHV alternator bolted up perfectly. All holes lined up unlike on Jolene’s swap.

The Throttle Position Sensor (TPS) had a completely different plug than my OHV unit, so I swapped the OHV TPS onto the new motor. Bolted up fine.

Last is the wiring. I see on Jolene’s swap his injector plugs were correct for the SOHC injectors. Mine are not. On my OHV harness the wires going into the injectors are all the same. A red and a white/ yellow. On the SOHC injector plugs they all have a common tan/white wire and then a smaller multi color wire that’s different on each plug. I spliced the new connector in going white to white and red to the multi color wire. I traced the wires back for injectors on both harnesses and confirmed that I had it wired it right. I extended everything and got everything plugged in.

Answer: As for the injector wiring, I would look at harness diagrams to see which ones do what. My buddy did the swap on an OB2 Ranger, and he too had to swap the injector plugs on the harness. I looked up injectors for a SOHC out of a 1998 Ford Explorer and it looks like those use the same plugs as your original wire harness.

1996 4.0 OHV to 2008 4.0 SOHC:

I’m Jolene’s buddy that also did the SOHC swap. Mine came out of a 2008 ranger and went into a 1996 Ford Ranger. So, I had OBD2. The swap was pretty easy and ran on my old OHV computer just fine.

So, for my IAC I just used the one on the SOHC motor and swapped the connectors.

For your injector wires, I had to swap mine too. My OHV harness was a big red wire and a smaller gray/white but that’s for cylinder #4. The SOHC harness had red and brown/blue wires.

I was going to say, OHV harness has one main color and the other is different, I just found my older injector connectors. They right side is the red and the left is different I’ll show in pic.

Have More Information:

If you have any information to add to this article, please use the ‘Submit Button‘ at the bottom of the page.