kishy

Active Member

- Joined

- Jan 9, 2018

- Messages

- 148

- Reaction score

- 58

- Points

- 28

- Location

- ON, Canada

- Vehicle Year

- 1985

- Make / Model

- Ranger, RCLB

- Engine Size

- 95 2.3 EFI Swap

- Transmission

- Manual

- 2WD / 4WD

- 2WD

When I bought my '85 in 2015, it had small base model mirrors. After a short time, I found a Bronco II in a junkyard with the big tow mirrors, which the sales brochure refers to as "Bright Western Swingaway Mirrors", and I retrofitted them onto my truck. They were great for several years, but in late 2021, something broke in the right side mirror and it wouldn't hold its position anymore. Fixing this, or even identifying what actually broke, was complicated by the fact that I had previously re-glued the glass into the mirror, and there was no way it was coming free without breaking.

Dorman makes a mirror that is designed to be a replacement for these, part 955180. I put one of these on my truck but I quickly grew to hate it for a couple key reasons:

Since that point, I've been hunting for a good convex right-side mirror in junkyards. In February, I was able to collect the pieces I would need for this project:

Last night, I decided to move forward with the mirror surgery. After all, I'm tossing around ideas for replacing the Ranger as it rusts away beneath me, so why not make it better first? /s.

Here's what I started with:

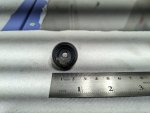

Detail view of the pivot assemblies:

Separating the glass from the mirror body. I evenly applied heat to the glass, then used an assortment of scraping and prying tools to firmly but very gradually lift the glass out of the body.

Next, we separate the aluminum back cover from the plastic body. This covers fasteners we need to get access to. It is held on with the same type of adhesive which is a relatively flexible silicone. I found it seemed to work best starting on one of the short sides.

Once the back cover is off, we can see the three small bolts that hold the pivot mechanism inside the housing.

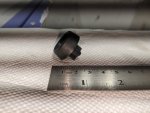

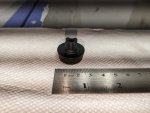

Taking apart and inspecting the pivot mechanism. Compared two of my available pivot balls, selected the one that seemed less rusted to garbage. Sanded it down to clean metal.

Sandblasted the pieces of the pivot.

Painted with an oil-based rust paint.

Upon closer inspection, I found that the 'socket' for the pivot ball stud has a crack in it. This is one of the failure points I've seen in the few mirrors I've looked at now, but this one doesn't seem too far gone to be worth trying to save.

I squirted some super glue inside the crack as well as lining the inside of the socket/cup, and will try to smooth it out once I see how it dries.

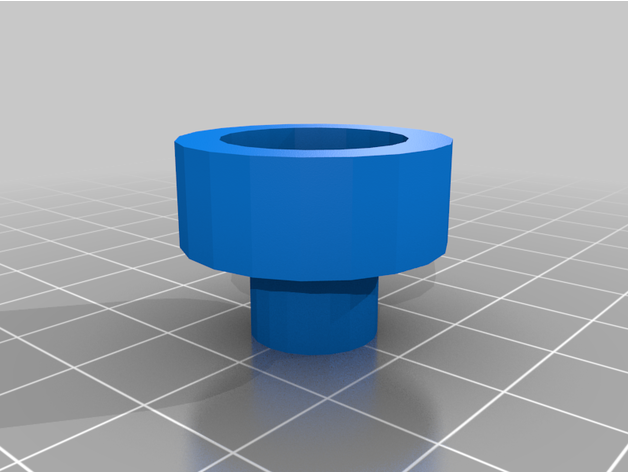

Status as of tonight: paint and glue are drying. If the glue looks like it'll hold up, I should be able to assemble the mirror when I get a few minutes, maybe this weekend. If the glue doesn't look like it'll work, I'll need to look for some sort of piece that can replace it, which might be tricky. It would be a pretty 3D-printable part for someone with the ability to model the part.

Dorman makes a mirror that is designed to be a replacement for these, part 955180. I put one of these on my truck but I quickly grew to hate it for a couple key reasons:

- The Dorman mirror is not convex, which is annoying. However, something even worse than that is that it seems to be very very slightly concave and seems to magnify as well, which gives an extremely narrow field of view.

- The Dorman mirror picks up vehicle vibrations which the stock mirror did not. The mirror glass vibrates at a high frequency when driving, causing headlights in it to have a dazzling effect and making it nearly impossible to get a good sense of what you're looking at in it.

Since that point, I've been hunting for a good convex right-side mirror in junkyards. In February, I was able to collect the pieces I would need for this project:

- One right-side convex mirror, but with a broken pivot mechanism.

- In the yard, I disassembled a left-side mirror with a seemingly good pivot mechanism, and removed the pivot mechanism.

There seem to be a few different ways that these mirrors fail:

- The cage which holds the spring rusts apart and the spring doesn't maintain tension on the ball stud anymore.

- The entire pivot mechanism rusts off of its fasteners, and the mirror assembly rattles loosely with the pivot mechanism still maintaining tension but no longer holding the mirror.

- The plastic cup/socket for the ball stud cracks and breaks apart, causing there to be no spring tension on the ball stud.

Last night, I decided to move forward with the mirror surgery. After all, I'm tossing around ideas for replacing the Ranger as it rusts away beneath me, so why not make it better first? /s.

Here's what I started with:

Detail view of the pivot assemblies:

Separating the glass from the mirror body. I evenly applied heat to the glass, then used an assortment of scraping and prying tools to firmly but very gradually lift the glass out of the body.

Next, we separate the aluminum back cover from the plastic body. This covers fasteners we need to get access to. It is held on with the same type of adhesive which is a relatively flexible silicone. I found it seemed to work best starting on one of the short sides.

Once the back cover is off, we can see the three small bolts that hold the pivot mechanism inside the housing.

Taking apart and inspecting the pivot mechanism. Compared two of my available pivot balls, selected the one that seemed less rusted to garbage. Sanded it down to clean metal.

Sandblasted the pieces of the pivot.

Painted with an oil-based rust paint.

Upon closer inspection, I found that the 'socket' for the pivot ball stud has a crack in it. This is one of the failure points I've seen in the few mirrors I've looked at now, but this one doesn't seem too far gone to be worth trying to save.

I squirted some super glue inside the crack as well as lining the inside of the socket/cup, and will try to smooth it out once I see how it dries.

Status as of tonight: paint and glue are drying. If the glue looks like it'll hold up, I should be able to assemble the mirror when I get a few minutes, maybe this weekend. If the glue doesn't look like it'll work, I'll need to look for some sort of piece that can replace it, which might be tricky. It would be a pretty 3D-printable part for someone with the ability to model the part.