Ranger Kip

New Member

- Joined

- May 2, 2010

- Messages

- 2,897

- Reaction score

- 10

- Points

- 0

- Location

- Wellsboro, PA

- Vehicle Year

- 1999

- Make / Model

- Ford Fleet

- Engine Size

- 3.slow

- Transmission

- Automatic

- My credo

- Confused and Intolerant

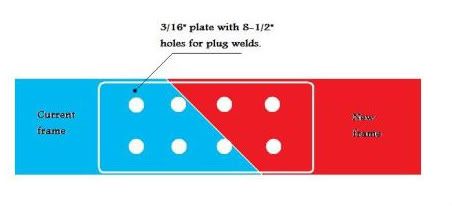

How would I safely weld my frame back together?

The mid section back is no good, so I wanted to salvage one from another ranger and weld it on, what should I do to make it safe and wont get much attention when getting inspected.

My budget is ultra low, as usual, so myself, my buddy Jason, and possibly adsm08 will be doing all the work.

(P.s. I have an electric MIG welder, a very very small stick welder and a grinder; but i can possibly take something into school to machine it)

The mid section back is no good, so I wanted to salvage one from another ranger and weld it on, what should I do to make it safe and wont get much attention when getting inspected.

My budget is ultra low, as usual, so myself, my buddy Jason, and possibly adsm08 will be doing all the work.

(P.s. I have an electric MIG welder, a very very small stick welder and a grinder; but i can possibly take something into school to machine it)