Ford Ranger Solid Axle Swap (SAS) Overview

Over the years many Ranger enthusiasts have opted to swap out the Dana 28 TTB or Dana 35 TTB front axle from their Ford Ranger 4×4 for a 4×4 solid axle. Swapping your Ranger’s TTB front axle for a full-width solid axle dramatically improves off-road strength, suspension travel, and durability. Popular swap options include the Jeep Dana 30, early Bronco Dana 44, F-150 Dana 44, and Dana 60 axles. This guide covers mounting points, radius arms, coil springs, trac bar mounts, and key upgrades to ensure a reliable and high-performing setup.

- Compare the most common front axle swaps for Ford Rangers: Dana 30, Dana 44, and Dana 60

- Learn about critical suspension components: radius arms, coil springs, C-wedges, and trac bar mounts

- Understand challenges like axle clearance, caster angle adjustments, and cross member modifications

- Discover popular upgrades, aftermarket kits, and manual hub conversions

- Get tips for achieving better off-road performance and reliability

If you’re planning a Ford Ranger solid axle swap (SAS), this article explains everything you need to know about choosing the right axle, mounting it properly, upgrading suspension components, and addressing potential issues. Whether you want the strength of a Dana 44 or the compact fit of a Dana 30, these insights will help you make an informed decision for your 4×4 Ranger project.

Why Most Ford Ranger Solid Axle Swaps Use a Dana 44

When performing a Solid Axle Swap (SAS) on a Ford Ranger, most builders choose a Dana 44 to replace the factory independent front suspension (IFS) or Dana 35 Twin Traction Beam (TTB). The Dana 44 offers a major increase in strength, articulation, braking capability, and steering reliability—making it the most common choice for Rangers built for serious off-road use.

Increased Strength and Durability

- Torque Handling: A Dana 44 can handle significantly more torque than factory Ranger front axles, reducing the risk of snapping axle shafts when tires suddenly regain traction.

- Larger Components: Features larger ring and pinion gears, thicker axle tubes (typically 2.5–3 inches), and stronger universal joints than stock Ranger equipment.

- Tire Capacity: While factory setups often struggle with oversized tires, a Dana 44 comfortably supports 35–36 inch tires.

Improved Braking and Steering

- Half Ton “Outers”: Dana 44 knuckles provide access to larger brakes, stronger hubs, and improved stopping power compared to Dana 35 components.

- High-Steer Compatibility: Dana 44 axles easily support high-steer or crossover steering systems, keeping steering components protected from trail damage.

TTB vs Solid Axle: Why Many Off-Roaders Choose a Dana 44 SAS

Ford’s Twin Traction Beam (TTB) suspension is well known for its performance in high-speed desert racing, thanks to its long wheel travel and ability to absorb large bumps. However, Ford Ranger owners who focus on slow-speed technical off-roading often prefer a solid axle swap with a Dana 44 due to its articulation, clearance, and steering advantages.

Articulation vs Wheel Travel

- TTB Wheel Travel: TTB excels at vertical suspension movement, allowing each wheel to move independently to absorb bumps at speed.

- Solid Axle Articulation: A solid axle physically forces the opposite tire downward when one tire climbs an obstacle, keeping more tires planted for maximum traction.

Ground Clearance

- TTB: As a TTB wheel compresses, the differential moves closer to the ground, increasing the risk of hanging up on obstacles.

- Solid Axle: When one wheel climbs an obstacle, the entire axle housing is lifted, maintaining better clearance under the vehicle.

Alignment and Camber Stability

- TTB Camber Change: TTB suspensions experience camber changes through their travel, which can cause tire wear and unpredictable handling on lifted trucks.

- Solid Axle Stability: A solid axle keeps both tires parallel throughout the suspension cycle, maintaining a consistent contact patch.

Steering Geometry

- TTB Steering: Most TTB Rangers use inverted-Y steering, which changes toe as the suspension cycles.

- Solid Axle Steering: Dana 44 swaps allow for crossover or high-steer setups that are stronger, simpler, and easier to keep aligned.

The Ford Dana 44 Solid Front Axle Suspension

The Ford F-150 / Bronco utilized a 3-link front suspension design featuring a Dana 44 solid axle. This system was engineered to balance off-road articulation with a tight 34-foot turning radius for better maneuverability.

- Dana 44 Front Axle: A “beefier” upgrade over the earlier Dana 30, featuring a roughly 8.5-inch ring gear and 30-spline axle shafts.

- Radius Arms: Two heavy-duty arms connect the axle to the frame. They are secured to the axle via cast iron “C-wedges” and use replaceable bushings at the frame-side pivot points.

- Coil Springs: Unlike many trucks of the era that used leaf springs, the Bronco used coil springs to provide a smoother ride and better suspension travel.

- Track Bar (Lateral Tracking Bar): A critical bar that connects the axle housing to the frame to keep the axle centered laterally under the vehicle.

The Biggest Obstacle When Using Coil Springs

Before we get into this, I need to point out that the full-size Dana 44 has a wider coil spring spacing than the Early Bronco Dana 44. In fact, the coil spring spacing is roughly 6.5″ wider than that of the Ford Ranger. That’s 3.25″ wider at each side. Coil springs have to be mounted vertical and will not be happy being bowed out.

To overcome this, you need to either move the upper coil bucket further out, move the C-wedges on the axle inward, or a combination of both. Other options include using coil overs which don’t have to sit perfectly vertical like a coil spring does or Narrowing the Dana 44.

Speaking of coil overs, you can build a whole custom link suspension with coil overs and not use any stock suspension components, but I suspect if you’re considering that you’re beyond needing any of this information.

Finally, I’ve seen people choose to simply mount the front axle with leaf springs instead of coils.

Swapping In The Ford Dana 44

The Ford Dana 44 is probably the easiest to swap using coil springs and radius arms.

When doing these swaps there’s essentially (5) mounting points to deal with:

1) The Coil Springs/Spring Buckets

The coil springs are responsible for the ride quality and handling as well as determining the vehicles ride height. Ford Ranger coil springs are smaller in diameter then the full-size coil springs. Owners commonly use coil springs designed to provide lift for the early Ford Bronco. Some owners have used their factory coil buckets, but a better option is the factory style coil from a 1978-1979 Ford Bronco.

Note how the early Ford Bronco coil spring fits the Ford Ranger coil bucket.

There are several triangular tabs that extend down from under the Rangers coil bucket. These tabs keep the spring in the bucket by entrapping the coil windings. The outer of these tabs may need to be bent back and flattened out. This is done because the full-size spring is larger, and its larger diameter windings, as well as their locations, will interfere with some of these tabs. You must make sure the inner tabs closest to the motor are still in their original positions. This will ensure the spring sets to the back of the bucket like the original Ranger springs did. Placement of the coil spring is very important. Do not rush this part of the swap. A mistake here could be costly later.

The tabs have been modified for the coil to fit.

Most people doing these swaps use the factory 1978-1979 Ford F-150 / Bronco upper coil spring mount bucket that was on the vehicle the axles came from.

James Duff offers a replacement Upper Coil Tower that replaces your Ford Ranger factory coil bucket. These are a nice upgrade if you’re doing an early Bronco Dana 44 or a Jeep Dana 30, but you should use an offset coil bucket with a full width axle swap.

Offset Coil Buckets

For swapping in a full width axle, you’ll want a set of offset coil buckets like these from James Duff. They’re made out of 1/4″ steel plate and extend out 2″ from the frame rail

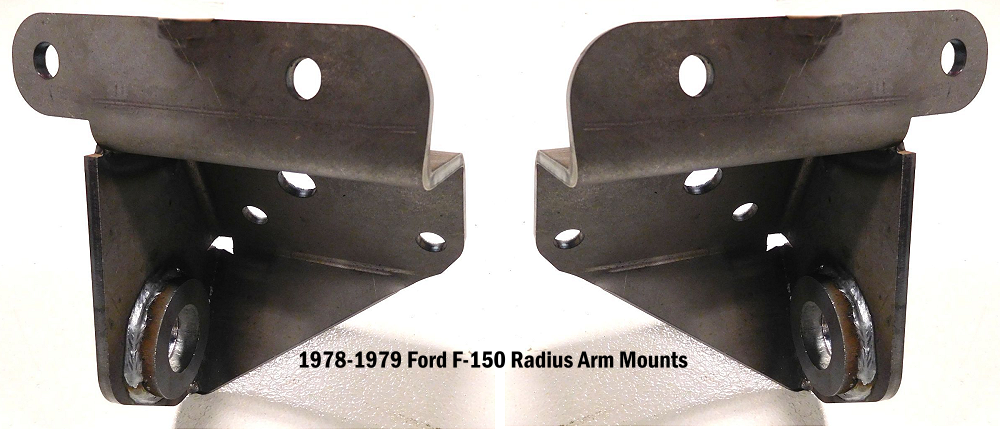

2) The Radius Arm Mount

To mount the radius arms, the owner of this 1993 Ranger used the rear hole in 1978-1979 radius arm brackets and lined it up with the bottom frame hole from the transmission cross member. Using those holes as a guide, the rest of the holes can be drilled. Attach the radius arm mount with 1/2″ grade 8 bolts. The 1978-1979 mounts provide a 4-inch drop to help caster.

James Duff offers a set of Dana 44 Extended Radius Arms to help maximize your suspension travel.

We actually have a whole page just on making your own extended radius arms and mounts. Check it out at: Build Your Own Extended Radus Arms

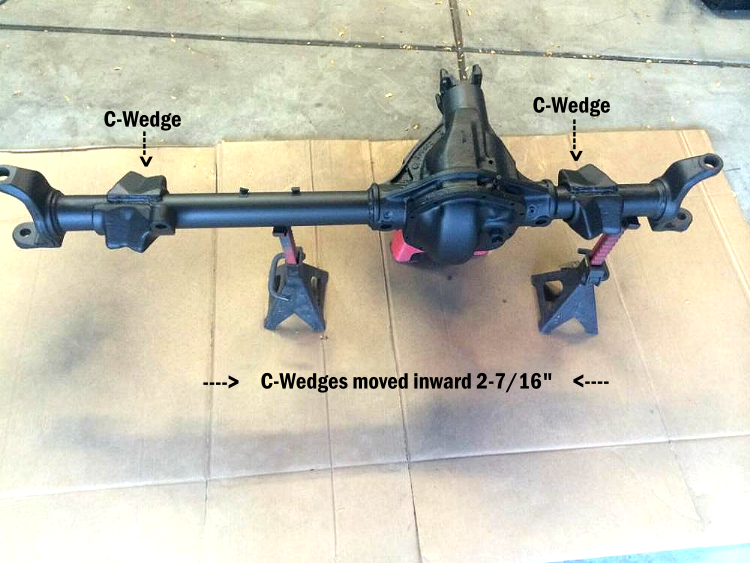

3) Axle Wedges or C-Wedges

The C-wedges are designed to fit snugly inside the curved “C” shape of the rubber or polyurethane C-bushings, which in turn are held by the radius arms. This setup secures the axle longitudinally (forward and backward movement) while still allowing for vertical articulation.

The angle of the C-wedges is crucial for establishing the correct caster angle, which is the angle of the steering axis when viewed from the side of the vehicle. A proper caster angle is essential for stable handling and preventing steering issues like “death wobble”. Different degree C-bushings (e.g., 2-degree, 4-degree, 7-degree) are used in conjunction with the wedges to adjust the caster, especially after lifting the vehicle’s suspension.

Various companies offer these C-Wedges that you can weld onto your axle tubes which allow you to mount the axle to your Ranger with a set of radius arms. The Axle Wedges below are from James Duff.

The bushings below mount between the radius arm and the wedges and are available with different degrees of caster to correct your alignment.

When Kirby swapped a 1979 Ford Bronco Dana 44 into his 1991 Ford Ranger, he cut the C-wedges, moved them inward 2-7/16″ with +2 degrees of caster.

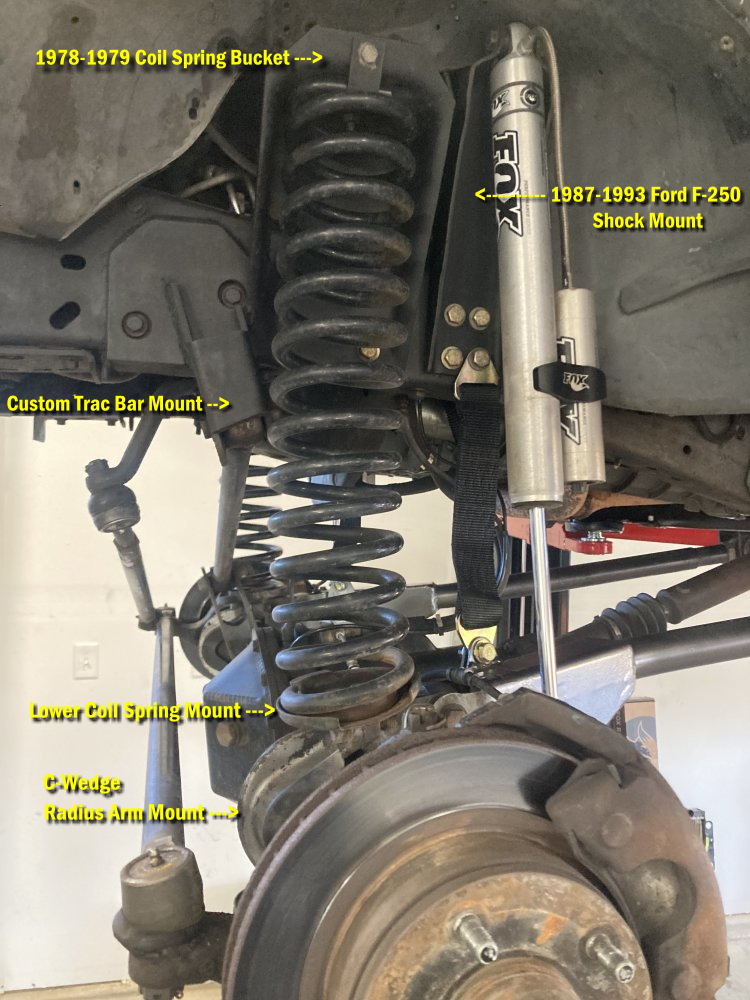

4) Lower Coil Spring Retainers (Seats)

If you’re using a stock set of radius arms, or making a set of your own, you may want to upgrade to a set of Heavy-Duty Lower Coil Spring Retainers (Seats) such as these from James Duff. You can see that these have a heavy-duty retainer that the coil twists into to prevent it from popping out.

5) The Track Bar Mount

The track bar mount is located on the driver side frame rail. It is the frame mount for the track bar that runs between the driver’s side frame rail and the passenger side of the axle. This is the mount that controls lateral (side-to-side) movement and keeps the axle centered under the truck. The location where the track bar attaches to the axle and the frame are the points where the axle pivots from during wheel travel. This is important to understand, because as the axle travels up and down, the distance from the axles pivot points start to make an arch like swing. This swinging effect will cause the axle to actually move toward the driver’s side as it raises or lowers.

People doing Solid Axle Swaps have made their own mounts, have adapted mounts built for other vehicles, and have used aftermarket universal mounts. Below are universal trac bar mounts from Poly Performance and Barnes 4WD. Ruff Stuff Specialties makes a universal mount as well.

The best option would most likely be the trac bar mount offered by James Duff. Their Trac Bar Mount is made specifically for the:

- 1983-1997 Ford Ranger

- 1984-1990 Ford Bronco II

- 1991-1994 Ford Explorer

This trac bar mount is a bolt-on installation using stock motor mount holes.

Putting It All Together

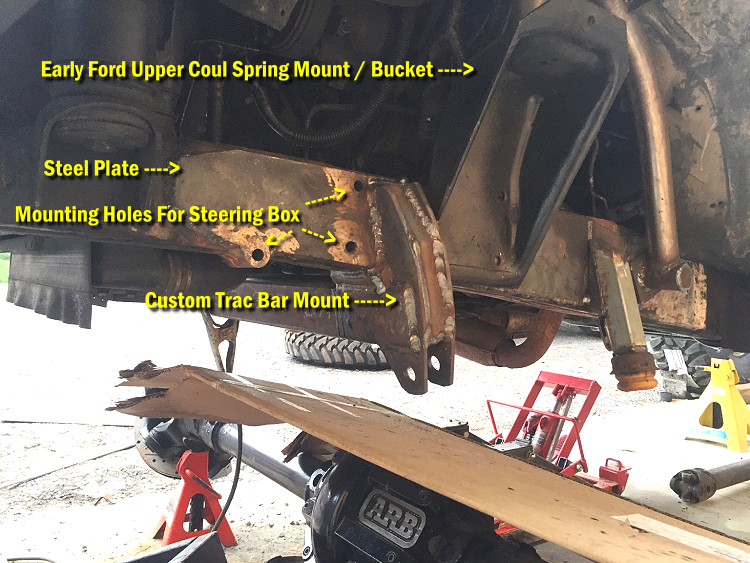

In the photo below of Kirby’s 1991 Ford Ranger SAS Build, you can see that he used a 1978-1979 Ford upper coil spring mount / bucket, a 1987-1993 Ford F-250 shock mount, and a custom trac bar mount to locate the axle and control its lateral movement.

Other Considerations:

Steering:

Owners have got steering linkage from www.partsmike.com. All you need to do is get accurate measurements from the holes on the knuckle-arms, making sure they are as straight forward as possible, then get a measurement from the pitman arm to the passenger side knuckle-arm hole. Call up Parts Mike and tell them the measurements.

Transmission Cross Member

Your new radius arm mounts will be in the way of your transmission cross member. Below is a cross-member custom made for a Dana 44 swap. It mounts between the radius arm mounts. The early Rangers used a transmission cross member that mounted inside of the frame rails instead of wrapping around to the outside of the frame rail. If you can find one, it may be an option if you don’t want to fabricate a new one.

Engine Cross Member

Due to the low-hanging engine cross member on the Ranger, a minimum of about 6-inches of lift height will be required to clear the differential when the driverside suspension compresses. Some trimming of the engine cross member is helpful as well.

James Duff Solid Axle Swap

You’ve probably realized by now that James Duff sells everything you need to swap a Dana 44 into your Ford Ranger / Bronco II using coil springs and radius arms. You could also use their components to swap in a Dana 30, but you’ll have to weld a set of their C-wedges onto your axle tubes to mount the radius arms.

Check out our article on doing a James Duff Solid Axle Swap at: James Duff Ford Ranger Dana 44 Axle Swap

1998-2011 Ford Ranger Solid Axle Swaps

There are a few differences doing a solid axle swap on these trucks.

These Ranger frames include “crumple zones” designed to collapse during a collision. These areas are structurally thinner and weaker, making them unsuitable for supporting the heavy vertical loads of coil spring towers or the lateral stress of a track bar without reinforcement. You’ll need to add a steel plate along the outside face of the frame.

You’ll have to remove your rack and pinion and install a power steering box from a 1976-1979 Ford F-150 or 1978-1979 Ford Bronco.

In the photo below you can see where the driver’s side frame rail was plated and a Ford upper coil mount was installed and how the frame was drilled out for the steering box. Notice that the lower mounting hole was made by welding a piece of DOM tubing to the bottom of the frame rail. You can also see that a trac bar mount was custom built and added.

Next you can see the coil spring, trac bar, and steering box in place as the suspension is being mocked up. It still needs a shock mount.

Here’s a look at the passenger side build of the same truck. I actually like how he designed a shock mount that also braces the upper coil spring mount.

The extended radius arms for this build are actually the stock radius arms that have been cut, and a thick wall DOM tubing was notched to slide over the arm and then welded in place. A threaded adapter is welded on the end to accept a Heim joint, and then it’s bolted into a custom crossmember the bolts to the frame.

Leaf Spring Front Suspensions

Another option to swapping in a Dana 44 is the use of leaf springs.

Here’s some pictures of a swap on a 1988 Ranger:

In the above (2) photos you’ll first see a piece of rectangular tubing that’s been slid inside of the frame rail after the front end of the frame (bumper mount) was cut off. The piece was then welded in with the gaps being filled in with plate.

The mount above (upside down) was built to cross the front of the new section of frame rail to mount the front of the leaf springs.

This bracket was made to mount the rear of the spring.

The Jeep Dana 30

The Jeep Dana 30 is a swap that’s becoming more popular. It has the advantages of a driver’s side differential and 5×4.5 wheel bolt pattern like the Ranger. It’s not any stronger than the Ranger’s stock Dana 35 though.

For more information on this axle swap and the Jeep Dana 30 axle, check out: The Jeep Dana 30

Frequently Asked Questions

Which solid axles can be swapped into a Ford Ranger?

Common Ford Ranger solid axle swaps include the Jeep Dana 30, early Ford Bronco Dana 44, full-size F-150 Dana 44, and Dana 60 axles. The Dana 44 is the most commonly used due to its strength, aftermarket support, and compatibility with coil spring and radius arm suspensions.

Why is the Dana 44 the most popular axle for a Ranger SAS?

The Dana 44 offers a strong balance of durability, articulation, braking performance, and steering options. It can reliably support 35–36 inch tires and allows the use of crossover or high-steer steering systems, making it ideal for trail and rock-crawling applications.

Are aftermarket components available for Ford Ranger solid axle swaps?

James Duff offer nearly all of the components required to perform a Ford Ranger solid axle swap, including coil buckets, radius arms, C-wedges, trac bar mounts, and steering solutions. While no single bolt-in kit exists, these components significantly reduce fabrication requirements.

Is a Dana 30 strong enough for a Ford Ranger SAS?

A Dana 30 can work for lighter-duty builds and moderate tire sizes, especially when upgraded with stronger shafts and U-joints. However, it is generally weaker than a Dana 44 and is not ideal for aggressive off-road use or larger tires.

Can I perform a SAS on a 1998-2011 Ford Ranger?

These Ranger frames include “crumple zones” designed to collapse during a collision. These areas are structurally thinner and weaker, making them unsuitable for supporting the heavy vertical loads of coil spring towers or the lateral stress of a track bar without reinforcement. You’ll need to add a steel plate along the outside face of the frame.

References

James Duff Ford Ranger Dana 44 Axle Swap

Kirbys 1991 Ranger Build Up and Solid Axle Swap

2002 Ford Ranger FX4 Twin stick SAS Build

4WD Solid Axle Swap (SAS) Featured Rigs

4WD Suspensions & Frames Discussion Forum

Other Articles

1993 Ranger 4×4 With Early Bronco Dana 44 Axle

Ford Bronco II With Early Bronco Dana 44 Front Axle

Ford Bronco II Dana 44 With Leafs

Dana 44 Solid Front Axle (Ford & Jeep Wagoneer)

4-Link tech – Measurements & Material Selection

Last Updated:

About The Author

Jim Oaks is the founder of TheRangerStation.com, the longest-running Ford Ranger resource online since 1999. With over 25 years of hands-on experience building and modifying Ford Rangers — including magazine-featured builds like Project Transformer — Jim has become one of the most trusted authorities in the Ford Ranger off-road and enthusiast space.

Since launching TheRangerStation.com, Jim has documented thousands of real-world Ranger builds, technical repairs, drivetrain swaps, suspension modifications, and off-road adventures contributed by owners worldwide. TheRangerStation.com has been referenced in print, video and online by enthusiasts, mechanics, and off-road builders looking for practical, and experience-based information.