Introduction

The Ford A4LD transmission is a four-speed automatic overdrive transmission used in the Ford Ranger and Bronco II, among other vehicles, from 1985 to 1995. The A4LD was the first Ford transmission to use an EEC-controlled torque converter lock-up clutch and later became the first to use electronic shift control (via a 3-4 shift solenoid). The French-built A4LD was created by adding overdrive to the front of the C-3 three-speed unit.

Technical Overview

The A4LD was developed by adding an overdrive gear to the existing, French-built Ford C3 three-speed automatic transmission. Its operation involves a sophisticated hydraulic system, a torque converter, planetary gear sets, clutches, and brake bands to achieve its gear ratios.

Type: Four-speed automatic with overdrive.

Fluid Type: It requires Mercon fluid (modern Mercon V is the recommended replacement).

Capacity: Approximately 9.5 quarts (9.0 litres).

Overall Length: 28.687-inches.

Transmission Code: T

Gear Ratios:

- First Gear: 2.474:1

- Second Gear: 1.474:1

- Third Gear: 1.000:1

- Fourth Gear: 0.750:1

- Reverse Gear: 2.111:1

Application: The A4LD was used in these vehicles:

- 1985–1990 Ford Bronco II

- 1987–1993 Ford Mustang (when equipped with the 2.3 I4)

- 1987–1988 Ford Thunderbird (when equipped with the 2.3 I4)

- 1985–1994 Ford Ranger

- 1986–1994 Ford Aerostar

- 1991–1994 Ford Explorer

- 1991–1994 Mazda Navajo

Single vs. Dual Solenoid Evolution

Single Solenoid (1985–1987): The original A4LD featured only one solenoid, which controlled the torque converter lock-up function. In these early models, the shift into 4th gear (Overdrive) was controlled purely by engine vacuum and a mechanical governor.

Dual Solenoid (1988–1994): Starting in mid-1988, a second solenoid was added to provide electronic 3-4 shift control (Overdrive engagement) via the engine computer (EEC-IV).

How to Identify the Version: You can verify which version is installed by looking at the electrical connector on the driver’s side of the transmission:

- 2-Pin Connector: Single solenoid version (Torque converter lock-up only).

- 3-Pin Connector: Dual solenoid version (Lock-up + Overdrive shift).

Note that while the dual solenoid design was introduced in 1988, some specific vehicle applications may have retained the single solenoid setup slightly longer depending on the engine and model year transition.

Common Issues

The A4LD transmission is known for certain vulnerabilities, largely due to its original design with several thrust washers and an initially weak overdrive section. Owners often report the following problems:

Shifting failures: Problems with shifting, particularly into or out of overdrive, are common.

Lack of overdrive: Often, this happens because the overdrive sprag locks up and doesn’t provide any give to the forward clutch spring pack. Shifting into overdrive rips the spring pack completely free, and the only way to fix it is to completely disassemble the transmission and replace the broken part.

Modulator valve sticking and band wear: A common issue involves the modulator valve sticking and the internal bands wearing out.

Torque converter clutch solenoid malfunctions: A faulty torque converter clutch (TCC) solenoid or its wiring can prevent proper gear engagement or cause lockup issues.

Low line pressure: Worn boost valve sleeves can cause low line pressure, which contributes to overall transmission problems.

Durability: The original design was not considered very robust, leading many owners and experts to recommend using updated internal parts if a rebuild is necessary.

Remanufactured units often incorporate updates like an improved, oversized boost valve and sleeve, premium sprags, and additional clutch plates to enhance durability and performance.

Check Out: A4LD Service Manual

Common A4LD Failure Points And Solutions

Overheating and Fluid Degradation

The Issue: Heat is the primary killer of the A4LD. Excessive heat burns the fluid, which then causes internal clutch packs and bands to wear rapidly.

The Fix: Install an external auxiliary transmission cooler in the return line to supplement the factory radiator cooler. Using high-quality synthetic fluid and performing regular fluid and filter changes can significantly extend life. Keep an eye on transmission fluid levels and status. Dark fluid or leaking fluid indicates a problem.

Vacuum Modulator Failure

The Issue: The modulator controls line pressure based on engine load. If the internal diaphragm ruptures, it can cause hard or erratic shifts. It may also allow the engine to suck transmission fluid into the intake manifold, leading to white smoke from the exhaust. You might lack third gear or lack the ability to do a proper 1-2 shift. When this happens, the modulator is defective. If you are doing repairs at any point and notice fluid coming out of the modulator vacuum line, it’s an indicator that the modular has failed or is about to fail.

The Fix: Regularly inspect the vacuum hose for leaks and replace the modulator if it fails. A vacuum gauge can be used to test the modulator’s integrity during diagnosis.

Worn Transmission Bands

The Issue: The A4LD uses three bands (overdrive, intermediate, and reverse). Worn bands lead to slipping in specific gears or a complete loss of gear engagement under load.

The Fix: Minor slipping can sometimes be addressed by adjusting the bands externally. If the friction material is gone, the bands must be replaced during a rebuild with updated materials.

Sticky Governor

The Issue: The governor on the output shaft controls shift timing based on speed. It is prone to sticking due to debris, preventing the transmission from shifting out of first gear.

The Fix: Clean the governor or install an anti-stick spring kit to ensure the valve moves freely.

Torque Converter and Solenoid Issues

The Issue: Later A4LD models use electronically controlled solenoids for overdrive and torque converter lockup. Faulty solenoids or wiring issues can prevent these functions or cause the vehicle to stall when coming to a stop.

The Fix: Test electrical signals at the 3-pin connector. Replacing faulty solenoids or a failing torque converter is often necessary to restore full functionality.

Low Line Pressure (Boost Valve Wear)

The Issue: Wear in the valve body, specifically the boost valve sleeve, leads to low hydraulic pressure. This causes soft, slipping shifts and eventual total internal failure.

The Fix: Install a Sonnax or shift correction kit during a rebuild to replace worn sleeves and valves with oversized, hardened components that better regulate pressure. When pressure increases, it keeps the clutch packs from separating, as well as keeping the clutches and associated bands from overheating.

Loose Kickdown Cable

Low Line Pressure: When the cable is loose or has too much slack, the transmission “thinks” the engine is at idle even when you are accelerating. This leads to insufficient line pressure, which prevents the clutches and bands from gripping firmly.

Premature Shifting: A loose cable often causes the transmission to shift into higher gears far too early (e.g., shifting into 3rd at 15 mph), which forces the internal components to work under load with low pressure, causing them to slip and eventually burn out.

Burned Components: Driving with a loose cable can quickly “cook” the forward clutch or bands because the constant micro-slipping generates extreme heat.

Front Seal Failure

The Issue: There could be fluid leakage at the front. Over time, the front seal can harden or simply wear out. When this happens, it doesn’t hold its shape and cannot stop fluid from leaking out. Transmission fluid provides cooling and lubrication. It could also be the front pump bushing.

The Fix: This isn’t a quick fix; to get to either the front seal or the front pump bushing, the transmission has to come off the vehicle.

Repeated Seal Failure: If you’re experiencing repeated front seal blowouts on an A4LD, the problem may not be the seal or your workmanship—it could be the bell housing. The A4LD bell housing bushing is finished in place, so the bore is often not perfectly centered. Always check whether the bushing is the original factory unit. If it is and shows less than .003″ converter hub-to-bushing clearance, do not replace it.

If the bushing must be replaced, verify that it is centered. Bolt the torque converter to the flexplate, rotate the engine, and check converter hub runout. Then install the bell housing and inspect contact at the bushing. Excessive contact on one side indicates an off-center bushing and requires bell housing replacement; slight contact is acceptable. Checking this first can prevent repeated front seal failures.

Crankshaft Pilot Sleeve / Bushing

The pilot bushing’s primary job in an automatic transmission setup is to center the torque converter pilot perfectly within the crankshaft. A worn or broken bushing allows the torque converter to operate out of alignment, which can lead to serious and catastrophic problems:

Vibration: Misalignment causes significant vibration that can be felt throughout the vehicle.

Front Pump Damage: The input shaft is supported in the transmission by the front pump. Misalignment places undue stress on the pump bushing and seal, leading to premature failure and fluid leaks.

Internal Component Wear: The “wobble” from the misaligned input shaft can cause accelerated wear to clutches, planetary gears, and the input shaft itself.

Catastrophic Failure: If the issue is ignored, the misalignment and resulting damage will eventually lead to the complete destruction of the transmission’s internal components and potentially the pump housing.

The Ford 4.0L Specific Issue

For the A4LD, 4R44E, and 4R55E transmissions used with the Ford 4.0L V6 engine, there is a known specific issue regarding a spacer (or pilot sleeve) made of a brittle powdered-metal material that sits between the crankshaft and the flexplate.

- This spacer is prone to cracking, breaking, and wearing where the torque converter pilot fits in.

- Sonnax, a transmission parts manufacturer, notes that it is a very common failure point and that inspecting or replacing this part should be routine maintenance whenever the transmission is out.

- They even recommend using updated, longer-piloted torque converters to provide more contact area within the sleeve, improving durability

The Most Problematic Years: 1985–1987

Early A4LD units are generally regarded as the least reliable.

Early Design Flaws: These units were the first attempts at adding an overdrive gear to the lighter-duty C3 3-speed transmission. They were notoriously spotty, particularly regarding the overdrive gear engagement.

Single Solenoid: These early versions used a 2-pin connector that only controlled the torque converter lock-up. The lack of electronic control for the overdrive shift meant these units depended entirely on hydraulic pressure and mechanical parts that wore out quickly.

Key Reliability Thresholds (1988–1989)

Reliability began to improve in mid-1988 when Ford introduced the dual solenoid setup.

1989 Improvements: Models from 1989 and later benefited from Ford’s broader engineering push to improve “Noise, Vibration, and Harshness” (NVH) and general durability, making them noticeably better than 1985–1987 models.

The A4LD, 4R44e And 4R55E Evolution Tree

The A4LD (Automatic 4-speed Light Duty) was the progenitor, introduced in 1985 by adding an overdrive unit to the front of the existing 3-speed C3 transmission. In 1995, it was upgraded with full electronic controls, splitting into two distinct models based on torque capacity:

4R44E: The “light-duty” version (rated for ~440 ft-lbs), used primarily for 4-cylinder and 3.0L V6 applications.

4R55E: The “heavy-duty” version (rated for ~550 ft-lbs), used for 4.0L V6 applications in the Ford Ranger and Explorer.

Key Technical Differences

Control Method: The A4LD uses a vacuum modulator and mechanical governor for most shifts, with electronics only for the 3-4 shift and torque converter lockup. The 4R44E and 4R55E are fully electronic, with the computer controlling all shift timing, feel, and line pressure.

Internal Strength: The 4R55E features a larger overdrive drum and higher clutch capacity than the 4R44E to handle the increased torque of the 4.0L engine.

Parts Interchangeability: While they share the same basic shell, many internal components like the pump, valve body, and case porting are different. You cannot directly swap an A4LD into a vehicle designed for a 4R-series transmission without major modifications to the vehicle’s computer and wiring.

5R55E – The Final Evolution of the A4LD

The 5R55E is mechanically a 4-speed transmission. It does not have an extra physical set of gears compared to the A4LD. Instead, it achieves a “fake” 5th gear through revised computer logic that engages the overdrive band while the transmission is still in 1st gear. This creates a gear ratio midway between 1st and 2nd, smoothing out the shift and improving fuel efficiency.

Interchangeability and Hardware

The “Frankentranny”: Because they share the same dimensional layout, custom builders sometimes put the upgraded internal “hard parts” of a 5R55E into the older A4LD case to improve durability.

Non-Swappable Externally: You cannot directly swap an A4LD into a vehicle designed for a 5R55E (or vice versa) without replacing the engine computer and the entire wiring harness, as the 5R55E is fully electronic while the A4LD relies on a vacuum modulator and mechanical governor.

Shared Components: Many service parts, such as torque converters, certain clutch drums, and gaskets, are compatible across the entire A4LD/4R/5R family.

Door Sticker Transmission Codes

Code T: Identifies the A4LD 4-speed automatic (typically used from 1985–1994).

Code T: Also commonly used for the 4R55E (the heavy-duty electronic version for 4.0L engines, 1995–1996).

Code V: Identifies the 4R44E (the lighter-duty electronic version for 2.3L/2.5L/3.0L engines, 1995–2001).

(Note: Code D is used for the successor 5-speed 5R55E introduced in 1997).

Other Identification Methods

If the door sticker is missing or unreadable, you can use these secondary identification methods:

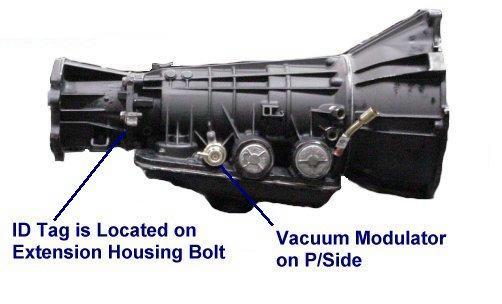

Transmission Tag: A small metal tag is often attached to one of the extension housing bolts on the driver’s side. It will list the specific model and assembly part number.

Pan Shape: All three transmissions share the same basic lineage and use an almost identical oil pan shape (nearly rectangular with a small cutout in one corner), distinguishing them from the larger 4R70W or C6 units.

Engine Application:

A4LD: Found behind 2.3L, 2.9L, and 3.0L engines prior to 1995.

4R44E: Primarily used with 4-cylinder (2.3L/2.5L) or 3.0L V6 engines from 1995–2001.

4R55E: Exclusive to the 4.0L V6 for the 1995–1996 model years before being replaced by the 5-speed.

The A4LD – Gloria Roozen

The A4LD 4-speed, overdrive transmission has been used in the Ranger/Bronco II/Explorer platform since 1986. As most of the early overdrive auto trannies, the A4LD was not real reliable in the early years. The first major change came with the introduction of the 4.0 in 1990. While still an A4LD, the 4.0 version was significantly stronger than the non 4.0 versions. It also had a computer-controlled torque converter lock-up. In 93.5 another major upgrade of this transmission occurred. In addition to the computer-controlled lock-up, the transmission also got a computer-controlled overdrive engagement. Internally, most of the thrust washers were replaced with Torrington bearings, which made the tranny much stronger.

While the A4LD has gotten a bad rap, it is actually a good strong transmission. There are modifications and upgrades available to this tranny. Better grade clutches and bands, better converters with improved lock-up clutches and brazed fins (stock converters were known for clutch failures, which takes out the entire trans), welded planetary cages, shift kits, and the ability to upgrade a non 4.0 tranny to 4.0 specs makes this tranny very versatile. At its strongest (off-road race application), these transmissions are holding up to V6’s making in excess of 300hp. Once the engines get much higher than that (depends on usage) the main shafts will start bending.

One of the most interesting upgrades available for this transmission is the off-road race package. This includes numerous valve body and internal modifications. These modifications are easily attainable from a good tranny man. What this modification does for you, is give you an automatic with all of the advantages of a manual……. and none of the downfalls. Run in drive, you can split the 3 gears with overdrive, and you can lock-up the converter in any of the gears. This gives a much greater availability of ratios and makes it really easy to keep the engine in its power curve. Also, because you can lock-up the converter whenever you wish, it also helps to keep the transmission cool. This mod also allows the transmission to be used completely manually.

When having an A4LD rebuilt, there are a couple of things that you need to make sure of. First and foremost, do not let a shop do a soft parts fix only (clutches, servos, and bands). This will almost ensure that you will have another repair needed right after the 1-year warranty is out. Other things you want to have replaced are forward one-way clutch (always), overdrive drum (stamped tin, replace if out of round or heat damaged), pump (Ford only, rebuilds are prone to failure), and the converter (get the better converter with the improved lock-up clutch and brazed fins). Also, get references from the shop and call the people. Just because they can rebuild TH350’s and C4’s does not mean they know what they are doing with overdrive trannies.

One of the best things you can do for your auto tranny is get the largest, aftermarket, stacked plate cooler you can fit behind your grille. The factory cooler is marginal at best, due to its being tied in with your radiator. Remember, with that set-up, if you overheat your engine, you will overheat your tranny. Heat is the biggest enemy of the automatic transmission. Change your fluid and filter every year, or every 12-15,000 miles if used hard. Use ONLY the fluid recommended by Ford. Only use synthetic fluid if it is required by Ford. With proper maintenance, these transmissions should last well over 100,000 miles. – Gloria Roozen.

The A4LD – From RonD

A4LD was Fords first light duty OD transmission, and it used a solenoid (TCC solenoid) for earlier torque converter lock up for better MPG, the engine computer controlled this and all future solenoids.

Any torque converter will lockup for direct drive when speeds get high enough, but that doesn’t happen driving around town, which is one reason automatics had much lower MPG than Manual transmission.

The TCC solenoid/computer has the benefit of driver input, i.e. gas pedal and brakes, so computer could lock torque converter earlier, and unlock it when stopping.

A4LD got a 2nd solenoid (3-4 shift) in 1988 for better shifting to OD, so it didn’t “hunt”, i.e. shifting between 3rd and 4th all the time.

If properly repaired or rebuilt, the A4LD lasts as long as any automatic.

A4LD came out in 1985 and 5R was last used in 2011, that’s 26 years for same automatic, and no matter what you might think, even Ford wouldn’t stay with a bad design for 26 years.

A4LD and the 4R and 5R were only for use with 4cyl or V6 engines, not V8s

A4LD Automatic Transmission Photos

Related Articles

Ford Ranger Automatic Transmissions

Ford Ranger Automatic Transmission Fluid Change

Installing a Torque Converter lock up switch on a Ford Ranger

A4LD Pressure Switch For Lock Up Torque Convertor

About The Author

Jim Oaks is the founder of TheRangerStation.com, the longest-running Ford Ranger resource online since 1999. With over 25 years of hands-on experience building and modifying Ford Rangers — including magazine-featured builds like Project Transformer — Jim has become one of the most trusted authorities in the Ford Ranger off-road and enthusiast space.

Since launching TheRangerStation.com, Jim has documented thousands of real-world Ranger builds, technical repairs, drivetrain swaps, suspension modifications, and off-road adventures contributed by owners worldwide. TheRangerStation.com has been referenced in print, video and online by enthusiasts, mechanics, and off-road builders looking for practical, and experience-based information.