Introduction

The Ford Ranger was offered with the 3.0L OHV Vulcan V-6 from 1991-2008 and used a 52mm throttle body. This article shows you how to install a 60mm throttle body from a 3.0L DOHC engine.

Intakes:

The 1991-2000 Ford Ranger 3.0L had a cast intake. The 2001-2008 Ford Ranger 3.0L had a composite intake.

(2000 Ford 3.0L Cast Intake)

(2001-2008 Ford Ranger 3.0L (Vulcan) Composite Intake and 2002 Ford Escape 3.0L (Duratech) Throttle Body)

Throttle Body:

The Ford Ranger 3.0L OHV (Vulcan) came with a 52mm throttle body.

Ford also offered a 3.0L DOHC Duratec engine with a 60mm throttle body in these vehicles:

- 2001-2005 Ford Escape/Mercury Mariner/Mazda Tribute

- 2005-2007 Ford Five Hundred, Mercury Montego and Ford Freestyle

- 1996-2005 Ford Taurus/Mercury Sable

Note: This is not the same engine as the 3.0L OHV Vulcan that came in the Ford Ranger.

Also note the 1987-2007 Ford Taurus came with the Ford 3.0L Vulcan engine. So, the 1996-2005 Ford Taurus could have either the Vulcan 3.0L, or the Duratech 3.0L DOHC engine.

The 3.0L Duratech engines should say “Duratec 3.0L 24V” on them.

You can also check the 8th digit in the Ford Taurus VIN:

-

-

- U – Vulcan 3.0L OHV

- 2 – Vulcan 3.0L OHV FFV

- S – Duratec 3.0L DOHC

-

The Parts:

You need the 2001-2008 composite intake to do this modification, so if you have a 1991-2000 Ford Ranger 3.0L, you’ll have to switch the cast intake for the 2001-2008 composite intake.

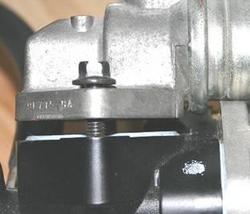

Here is a comparison between the stock Ford Ranger (left) and Ford Escape (right) throttle bodies view from mounting flange:

Comparison between the stock (top) and Escape (bottom) throttle body height:

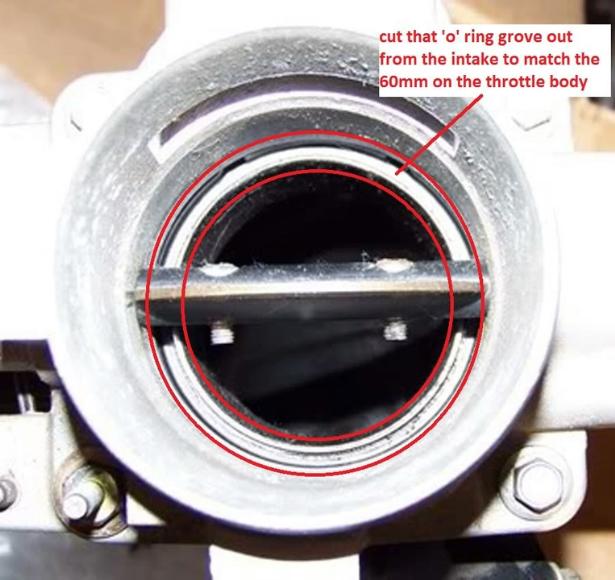

Detail view of area to be ported on the stock 2001 and upper intake manifold for fitment of 60mm throttle body:

You can see the lip of the intake when looking through the throttle body. This will have to be ported to allow for smooth air flow:

Detail view of voids (gaps) in air bypass channel in Escape throttle body that must be filled with JB Weld or other metal epoxy to avoid leaks:

Detail view of clearance issue between IAT and Escape Throttle Body:

Modifications:

View of the port work done (on intake) to accommodate the larger throttle body, also shows epoxy used to fill in the voids surrounding the inlet to allow gasket material to be used instead of stock O-ring:

View of Gasket material cut to fit opening and mounting points:

View of material removed to provide clearance for IAT sensor:

View of installed unit awaiting installation on Lower Intake Manifold:

More On Porting The Intake:

Complete:

Related Articles:

1991-2009 Ford Ranger 3.0L V-6

1999 Ford Ranger V6 3.0L FFV Head Gasket Replacement

Ford Camshaft Position Sensor (CMP) / 3.0L, 4.0L & 5.0L

3.0L Camshaft Position Sensor – Synchronizer

Last Updated:

About The Author

Jim Oaks is the founder of TheRangerStation.com, the longest-running Ford Ranger resource online since 1999. With over 25 years of hands-on experience building and modifying Ford Rangers — including magazine-featured builds like Project Transformer — Jim has become one of the most trusted authorities in the Ford Ranger off-road and enthusiast space.

Since launching TheRangerStation.com, Jim has documented thousands of real-world Ranger builds, technical repairs, drivetrain swaps, suspension modifications, and off-road adventures contributed by owners worldwide. TheRangerStation.com has been referenced in print, video and online by enthusiasts, mechanics, and off-road builders looking for practical, and experience-based information.