Ford Member BlackBII found away to upgrade the lock nuts on his Dana 35 TTB to keep them from coming loose.

According to him:

I did do this mod to prevent the nuts from coming loose. The way Ford did the locknuts is just too unreliable; the inner nut has a small pin on it, and over the years with many RBV’s I have had that pin shear off many many times. The pin and the locking tabs are just too small, even on new Ford/Spicer nuts. They are also difficult to get the torque spec correct because when after tightening the inner nut to set the bearing, you then have to torque the outer nut to 200+ft-lbs in order to prevent them from coming loose, and because of the small/crappy pin and locking tab on the washer, torquing the outer nut will tighten the inner one a bit, making the bearing too tight. Overall, it’s just a poor design that leads to nuts coming loose and bearing failure. It’s the thing I hate most about the Dana 35 TTB hubs.

The screws lock the outer nut and outer washer together, and the tab on the outer washer prevents it from coming loose. With this design, there is no need to over-tighten the outer nut, which can then over tighten the inner nut(the pin and tabbed washer are supposed to prevent this, but in my experience they don’t do a good job of this)

I have a few thousand miles on mine and they are working great.

He started out by purchasing (2) JA000865 Spindle Nut Lock Washers:

It’s important that you understand how the lock nut and lock washer works. The inner lock nut has a pin that sticks out of it. The inner lock washer has holes drilled in it, and a tab that locks in to a groove on the spindle. Sorry about the blurry photo below. Hopefully it’s good enough for you to get a visual understanding. When the lock nut has seated the bearing, the lock washer is slid over the spindle, and the holes in the washer are lined up with the pin in the lock nut. This is suppose to keep the inner nut from coming loose. The problem is that these pins often break off, so the lock nut isn’t locked in place. Over time the lock nuts can come loose causing premature wear of the wheel bearing.

BlackBII overcame this by remove the stock pin, drilling out the pin holes with a 1/8″ carbide drill bit, and installing 1/8″ steel dowel pins.

The stock lock washer was used as a guide to drill holes in the new JA000865 lock washers for the 1/8″ pins to lock in.

BlackBII then purchased a pair of Dorman 618-041 spindle locker washers and cut off the outer tabs. :

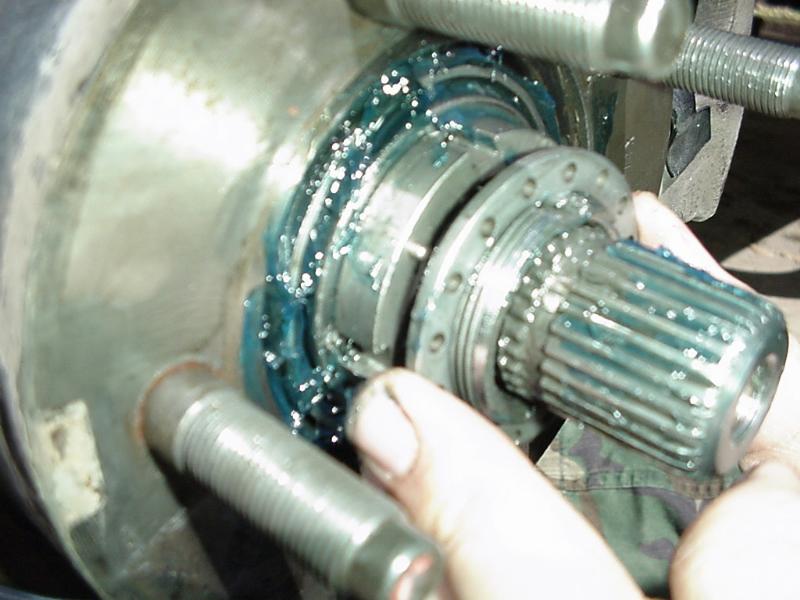

This would be the outer lock washer that would help secure the outer lock nut. He clamped the factory inner washer with the existing holes onto the outer lock nut, and center punched two holes exactly opposite from each other. He drilled the two holes with a carbide drill bit, and then used a quality 8/32″ tap and tapped them.

He purchased (4) quality 8/32″ Allen drive cap screws (he wasn’t sure if they were 1/2″ or 5/8″ long) so they could go through the holes in the outer lock washer, and thread in to the lock nut to secure it in place.

The Allen head cap screws do not interfere with the operation of the locking hubs. BlackBII reports that he has a few thousand miles on his truck now since performing this modification.

Links:

You can read more about this HERE.

BlackBII’s 1989 Ford Ranger 4×4