- Joined

- Nov 6, 2012

- Messages

- 1,085

- Points

- 1,601

- Age

- 32

- City

- San Antonio, TX

- Vehicle Year

- 1984

- Transmission

- Automatic

kadams can i get the diagram containing this little device

![]() Welcome Visitor! Please take a few seconds and Register

for our forum. Even if you don't want to post, you can still 'Like' and react to posts.

Welcome Visitor! Please take a few seconds and Register

for our forum. Even if you don't want to post, you can still 'Like' and react to posts. ![]()

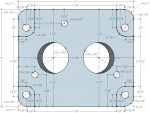

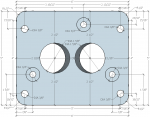

I suggest that you move the tbi backward on the plate 1/8", doing so will make the throttle cable bracket fit perfectly. on our first one it was centered and the bracket needed to be bent toward the tbi so that the cable would have enough slack to attach.

you will need to extend the plate to be at least 1/8" behind the back bolts (1/4" if you move the tbi back 1/8") maybe more, you'll have to set the tbi gasket on there and see. so that you don't get a massive vacuum leak on the IAC port. if you look at the pic of the one I did, you will see it has a decent sized overhang on the back, this was for that reason. rico did have a tiny (and I mean tiny) bit of plate/hose interference with the brake booster hose. but nothing major.