AlaskanRider

Well-Known Member

- Joined

- Apr 5, 2011

- Messages

- 165

- Vehicle Year

- 1991

- Transmission

- Manual

Hey, so I am finally doing it. Ive had my d35 ttb bouncing around in my bed for a month now and finally have the steel and time to mate it to my offroad 2wd frame.

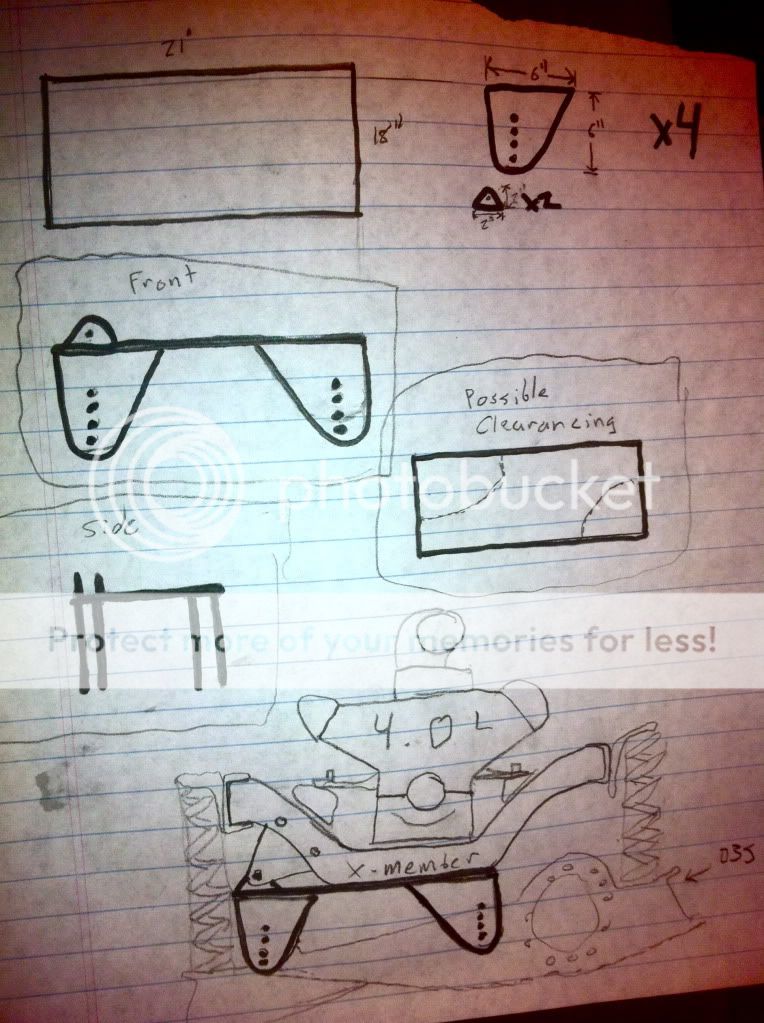

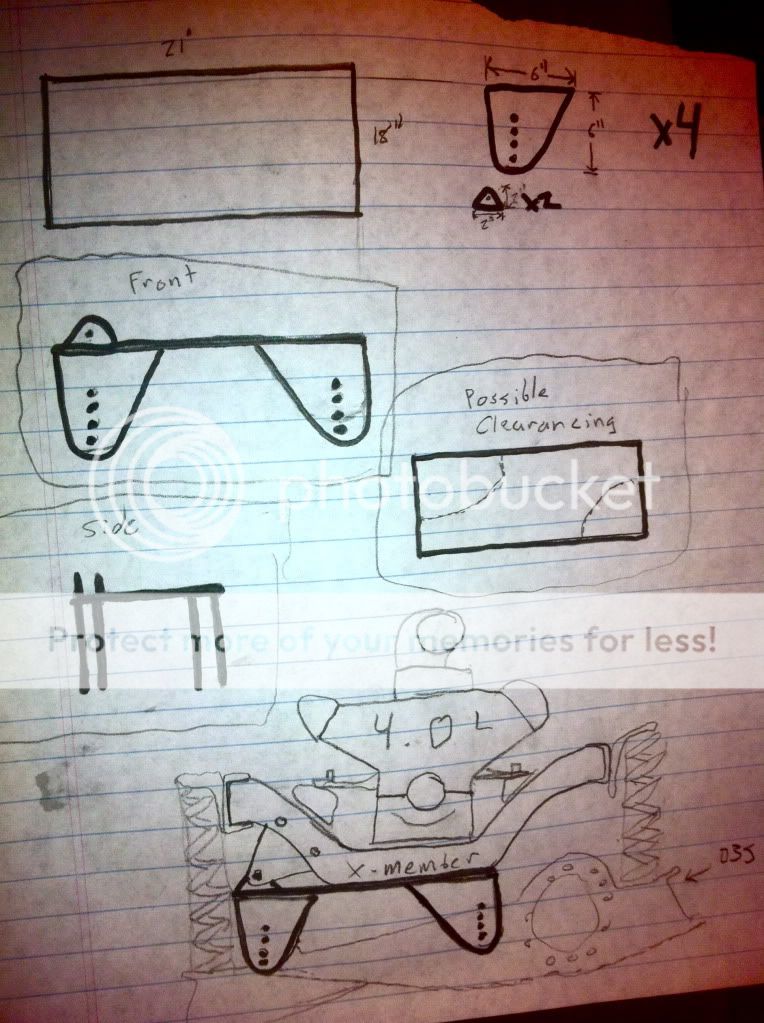

I was hoping for some advice on my design. I have a 2'x2' piece of 3/8", I think it will be solid enough. Below is my design.

Sorry about the pic, it is really the best I could do with my stupid camera. Proportionally, it's a little skewed, but the basic design is there. I may do A bit of clearancing on the 18"x21" plate, and on the bracket closest to the dif, but other than that, it's all there.

I am trying to accomplish this with the least amount of lift that I possibly can, and still clear everything. I am anticipating at least 1" of lift, but might actually need closer to 4". I hope to not exceed 4".

The design is based on the TTB jeep "juggy" build on pirate 4x4, just a little wider to accomodate the d35.

I will probably weld a beads along the bottom of the x-member, and it will bolt to the passenger side TIB bracket.

Thoughts? Suggestions? I am really open to advice, as I haven't done anything like this before.

The only thing I am sure about, is that I want to do this and I don't want to buy a 4x4 ranger. Also I am sure that I currently lack funds for an SAS. Any other advice would be greatly appreciated.

Thanks in advance to anyone who can help me out.

I was hoping for some advice on my design. I have a 2'x2' piece of 3/8", I think it will be solid enough. Below is my design.

Sorry about the pic, it is really the best I could do with my stupid camera. Proportionally, it's a little skewed, but the basic design is there. I may do A bit of clearancing on the 18"x21" plate, and on the bracket closest to the dif, but other than that, it's all there.

I am trying to accomplish this with the least amount of lift that I possibly can, and still clear everything. I am anticipating at least 1" of lift, but might actually need closer to 4". I hope to not exceed 4".

The design is based on the TTB jeep "juggy" build on pirate 4x4, just a little wider to accomodate the d35.

I will probably weld a beads along the bottom of the x-member, and it will bolt to the passenger side TIB bracket.

Thoughts? Suggestions? I am really open to advice, as I haven't done anything like this before.

The only thing I am sure about, is that I want to do this and I don't want to buy a 4x4 ranger. Also I am sure that I currently lack funds for an SAS. Any other advice would be greatly appreciated.

Thanks in advance to anyone who can help me out.