85_Ranger4x4

Wallers in rivers

TRS Forum Moderator

TRS Event Staff

💻 TRS Socials

Article Contributor

TRS Event Participant

TRS 20th Anniversary

VAGABOND

OTOTM Winner

V8 Engine Swap

TRS Banner 2010-2011

- Joined

- Aug 7, 2007

- Messages

- 36,087

- Points

- 2,001

- City

- Frankfort

- State - Country

- IA- USA

- Vehicle Year

- 1985

- Engine

- 5.0

- Transmission

- Manual

The A/C has worked but has never really been right, it won't exactly freeze you out and the compressor never cycles. Dad was never super happy with the pressures and suspected something with the orifice tube. When I used it on the road before when I couldn't run with the windows down I would kind of manually cycle it, run it until I was cool and then turn it off until I couldn't stand it, rinse and repeat.

Well for the vagabond trip I am going to have a 4yo navigator with and I want him to not only be comfortable but I also want to be able to hear him... so good A/C would be nice.

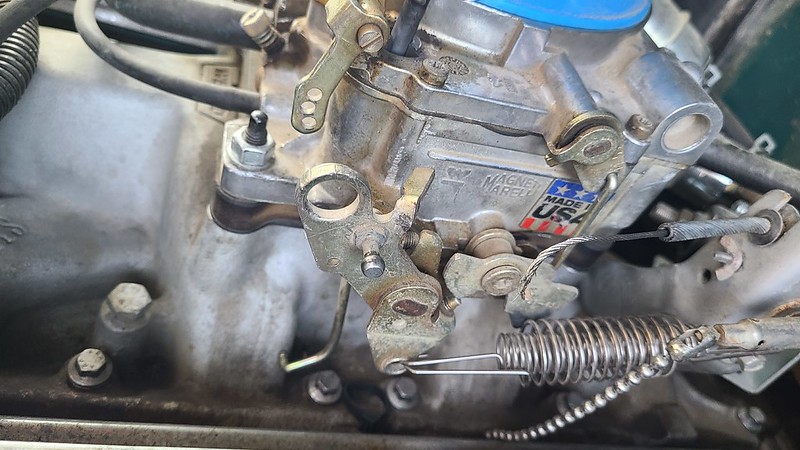

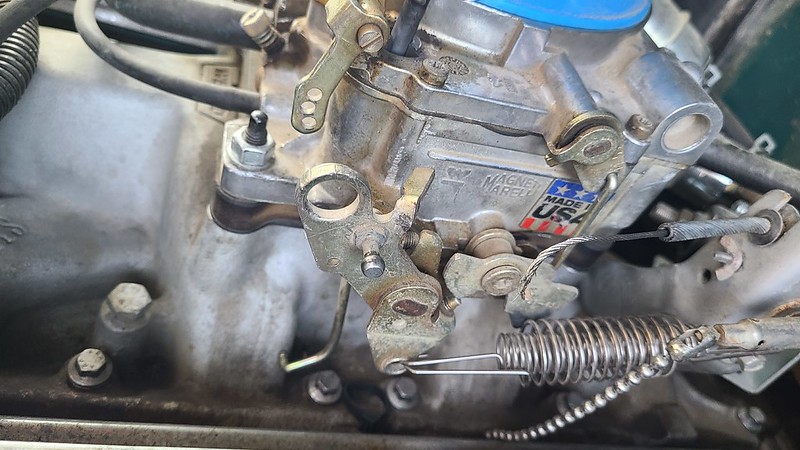

So this morning I went to back it out and pop, gas pedal went to the floor. My heart sank, this thing has to be ready to set sail early Saturday morning and throttle cables are unobtanium.

Huge shoutout to @r-hindl71 for doing an emergency mayday run to the only u-pull-it in Omaha that showed a first gen. Of course it was a 2.3... and the 2.3 cable is a lot longer than a 2.8 cable.

It was of course the same inside the cab and it clipped into the firewall the same. The engine bay side needed rerouted over the woods and thru the river but it in the end it does work.

So once we were able to attain more than idle speed I sneaked it into town and had dad evacuate the A/C so I could check out the orifice tube.

Ran it home and pulled it apart... fun fact when you get the evaporator with the orifice tube they don't actually put the o-rings on the tube. Instructions are of course nil as well.

And it was in backwards too for whatever difference that would make.

So I learned two things tonight

1. If you leave off the orings it is very easy to remove the orifice tube down the road

2. If you install it backwards it is very hard to grab because the short end doesn't reach the end of the tube like it does when installed correctly.

Well for the vagabond trip I am going to have a 4yo navigator with and I want him to not only be comfortable but I also want to be able to hear him... so good A/C would be nice.

So this morning I went to back it out and pop, gas pedal went to the floor. My heart sank, this thing has to be ready to set sail early Saturday morning and throttle cables are unobtanium.

Huge shoutout to @r-hindl71 for doing an emergency mayday run to the only u-pull-it in Omaha that showed a first gen. Of course it was a 2.3... and the 2.3 cable is a lot longer than a 2.8 cable.

It was of course the same inside the cab and it clipped into the firewall the same. The engine bay side needed rerouted over the woods and thru the river but it in the end it does work.

So once we were able to attain more than idle speed I sneaked it into town and had dad evacuate the A/C so I could check out the orifice tube.

Ran it home and pulled it apart... fun fact when you get the evaporator with the orifice tube they don't actually put the o-rings on the tube. Instructions are of course nil as well.

And it was in backwards too for whatever difference that would make.

So I learned two things tonight

1. If you leave off the orings it is very easy to remove the orifice tube down the road

2. If you install it backwards it is very hard to grab because the short end doesn't reach the end of the tube like it does when installed correctly.