- Joined

- May 15, 2020

- Messages

- 4,543

- Points

- 601

- Age

- 70

- City

- Atlanta

- State - Country

- GA - USA

- Other

- Manufacturers factory tour, maybe big dealership tour

- Vehicle Year

- 1997 1987

- Vehicle

- Ford Ranger

- Engine

- 4.0 V6

- Transmission

- Manual

- Total Lift

- 97 stock, 3” on 87

- Total Drop

- N/A

- Tire Size

- 235/75-15

- My credo

- Never put off ‘til tomorrow what you can put off indefinitely

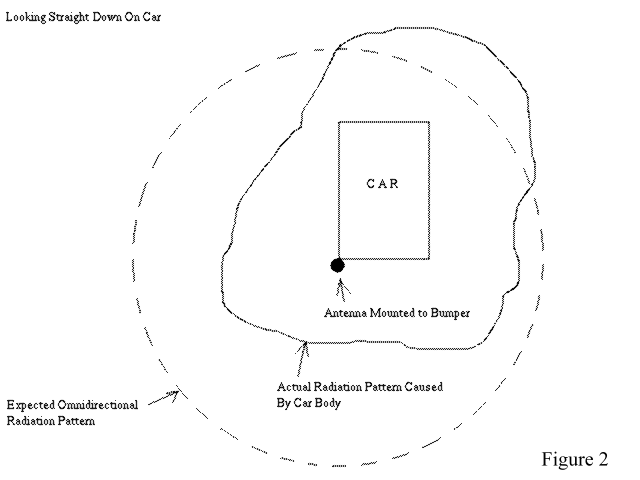

The antennas behind the cab appear to be high enough over the roof to work pretty well but Eric is correct that the one on the roof is better. If you are going to use only one of the duals, use the one on the passenger side since that will angle the strongest transmission lobe toward oncoming traffic. The driver's side would do the opposite. A lot of antennas use the vehicle body as the opposite side of the antenna. So, if the antenna is in one corner, the the focus is going to be in the opposite corner, roughly.

As far as the connector, I don't know enough about split systems to be of any real help there since I've never had a vehicle big enough to use dual whips. I'm guessing you should really use the connector designed for a single antenna. This is the point where I would refer you to a radio shop that deals with customers who drive big trucks. They should know if using only one side of a split will work or not. There may be something in the radio requiring the load the be balanced off of that connector but that is only a guess on my part.

@ericbphoto, remember this is all for play, a big toy. I’m not looking for the best performance, I’m just looking for SOME performance. But I’m trying to maintain the cool dual antenna look.

@sgtsandman, I understood everything you said. Just conceptually, go with me here.

I don’t have it at my fingertips, but the correct spacing is something like seven or 8 feet, and I couldn’t get that unless I move the antennas out like 18 or 20 inches from either side of the cab which would look ridiculous.

I sort of know the reason why, but a correct dual antenna cable has the 50 something ohms on the single legs to the antennas; but the base of the Y is 70 something ohms for it to work right. I have the exact numbers, but I don’t have them handy, but that’s not important. The other option is to run the two single cables all the way to the connector on the back of the radio and have them join at the connector. That is actually the set up I have.

If you think about it, the center signal strand in the coax is shielded the whole distance of the wire. Theoretically, nothing in or out until it gets to the exposed antenna. If I plug the set up into the back of the radio, but I disconnect one leg at one antenna, would you agree the other antenna should work OK as if it was on a single wire?

I think the only thing that would make a difference there is if I had the “Y” set up and if only one antenna was connected, there would be a portion of the connection going through the higher ohm wire. With the “V” set up I have, one leg would just be dead/neutral, and the other one should work properly as a continuous 50 ohm wire. Yes, no?

And I agree, that without moving mine, there should be enough of the antenna exposed that it should work “OK” even though part is shielded by the cab. However, I was thinking that the driver side would project best to the left rear, side and front left (oncoming traffic) and vice versa for the passenger antenna. Was that a typo?

One last thought. If one of the twins has no cable on it, the wire in the antenna is not attached to anything, not grounded. So I’m thinking if I leave it in place, that shouldn’t interfere with anything.

And the second last thought, but my headache rack, and all the lights, and the racks on the roof, are a large mesh of aluminum and obviously it’s all grounded. I don’t know how to say this correctly, but is there a point at which it could be “over grounded,” and actually suck the signal out of the air? I don’t think so, I think grounded is grounded, and, that you can have too little, but you can’t have too much. Again, that should make the signal from the driver side antenna work best straight out at 90°, pretty good heading backwards, and adequately heading forwards. Yes no?

And I am interested in the theory and the input and I greatly appreciate it, or I wouldn’t be asking the question. I can relatively easily try every option simply by connecting and disconnecting connectors. But I would have to ride up and down the road and chat with whomever to check it out.

Whadda ya think?

I let it idle for a minute and gave it a few revs increasing the rpm's each rev and still no squeak.

I let it idle for a minute and gave it a few revs increasing the rpm's each rev and still no squeak.  I finally found the issue! Wrong pulley was installed when my friend changed it when the original went about 8 years ago. The pulley was changed then because the bearings in it went so it was squeaking then and has squeaked ever since.

I finally found the issue! Wrong pulley was installed when my friend changed it when the original went about 8 years ago. The pulley was changed then because the bearings in it went so it was squeaking then and has squeaked ever since.