Introduction

You’ve done the Ford NP205 Twin Stick Mod to your transfer case and you’re looking at the $300 lever kits online and wondering how hard it would be to make them yourself. Here’s how to DIY your own Twin Stick Levers.

Disclaimer: The Ranger Station.com, The Ranger Station.com Staff, nor the original poster are responsible for you doing this modification to your vehicle. By doing this modification and following this how-to you, the installer, take full responsibility if anything is damaged or messed up. If you have questions, feel free to PM the original poster or ask in the appropriate section of The Ranger Station.com forums.

Tools Needed

Angle Grinder

Marker

Welder

Hacksaw / chop saw to cut steel

Possibly an oxy-acetylene torch to bend steel

Drill (preferably a drill press)

9/32″ drill bit (for steel)

5/8″ drill bit

Bench vice

Vice Grips

3/8-28 UNF thread die with handle

Parts Needed

Two NP-205 Shift Levers w/plastic bushings

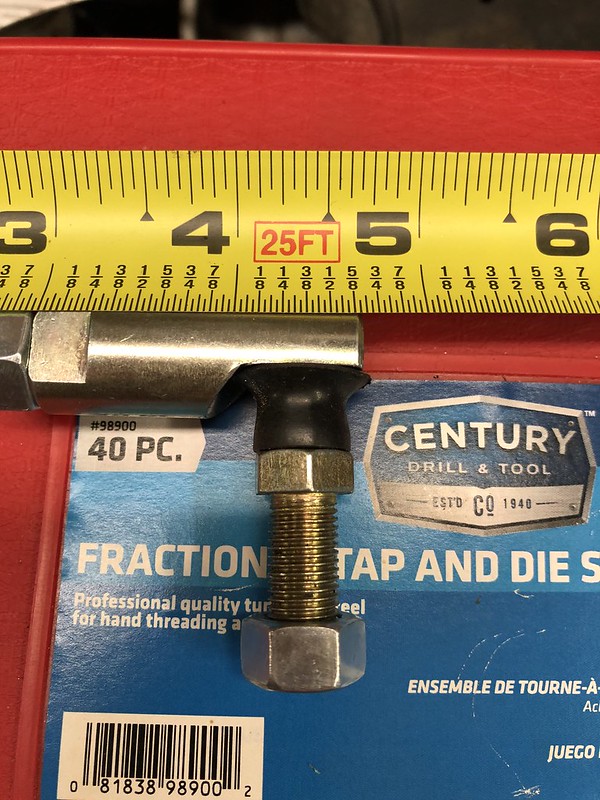

9/16″x3/4″x2.5″ Baum Hydraulic part # CB09-1218

Bolt

4x ball joints (I used 4x Rotory 2210)

3/8 Threaded Rod (or whatever you need to fit the joints you use)

2x 1″ long 3/4″ DIA seamless tubing

1’x1″x3/16″ Steel Strap (flat bar)

2x 3/8×1-1/4″ cap screw with nuts (double nut if you can)

4x 3/8-25 UNF nuts

Shift Knobs (kind of optional, anything will work. Stock knobs will work if you don’t care about the patterns) 1/4-28 thread for a stock NP-205 lever.

Truck Prep – Easiest with the carpet and floorplate out of the truck.

Procedure

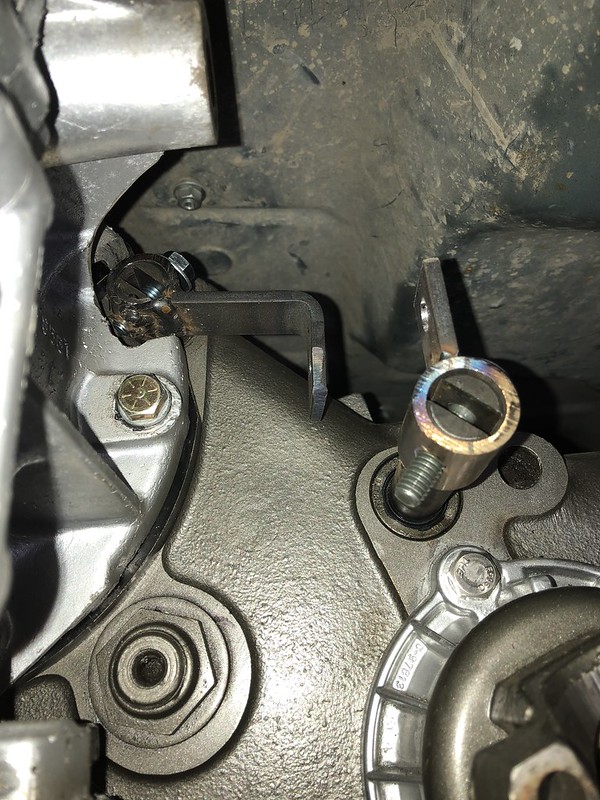

Step 1. Mount the levers on the transmission, see how they interact with things in the cab. The dash, the seat, other shifters, your leg etc. I used one lever from a married NP205 and another one from a divorced.

Purely unintentional but they had slightly different angles/height which helped keep them apart.

Step 2. Remove the levers from the trans, cut the bar off the bent part and grind it flat.

Whichever one you want for your outside lever needs to be have part of the base shortened up to fit right, cut/grind that down so you can still have one plastic bushing in it, the bronze bushing should protrude slightly with both levers on it.

The inside lever will need some clearancing at the top, so it doesn’t bind with the outside lever. Mr. angle grinder to the rescue again.

Once it is ground flat drill a 5/8 hole it in it so the levers will fit back in the pivots the same as they did originally.

Trim levers to fit and angle them how you want. Reinstall bases back in truck and mark how you want the levers to sit with the marker. Both height and angle. Depending on how things play out you may need to heat the levers with a torch to get them where you want them, I did not need to. I do have mine angled more ahead than anywhere else though.

Weld the levers to the pivots. I left enough lever out the bottom (like 1/2″) to weld top and bottom like Ford did originally. Install in truck with knobs.

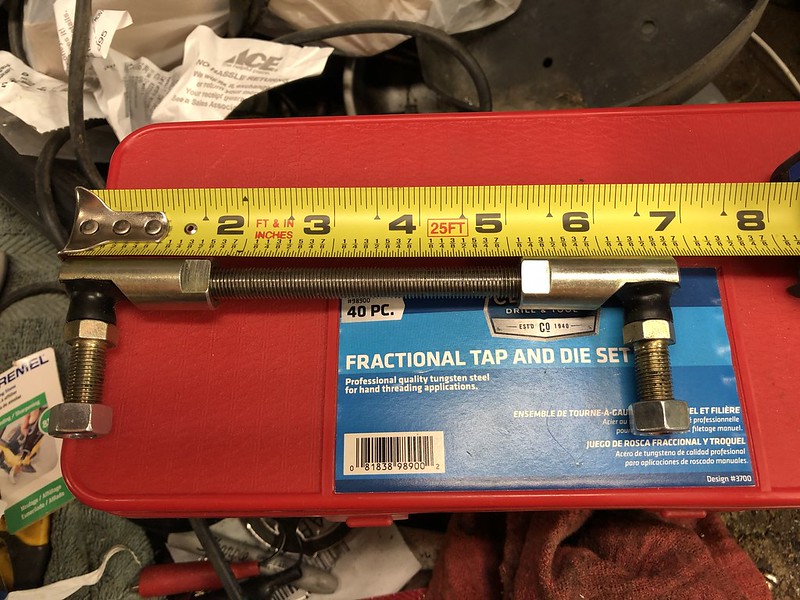

Drill holes in the seamless tube so they can be bolted onto the shift rails. Bend the straps so they line up with their respective levers using the torch and bench vice and vice grips. Drill a 3/8″ hole on the outer end.

Install the joints on the levers and brackets. Put the t-case in neutral and kind of figure where you want the levers to be in neutral (the middle adjustment) Put the t-case in high and low and eyeball the levers movement and see if you want to adjust anything. Remember for a street driven truck the left lever will be in the center and the right lever will be to the back (2HI) most of the time.

Measure for the threaded rod, remember it needs to go inside the joints and that is easier to make it shorter than it is to make it longer. Here is what I ended up for actual working lengths, your results will vary.

Clean up the threads with the die after you cut the threaded rod and install with nuts. Make sure you are happy with how everything works; you have some adjustment with the threaded rod if you need it. Then trim floor plate to fit the lever travel and install.

Optional, now if you wanted to, go ahead and remove, clean, paint, and reinstall the shift levers.

Reinstall your interior, add shift boots if wanted and have fun!

Feedback From Shran:

Great work… factory 205 shifters are a dime a dozen and that method is an excellent option. If your budget allows and/or you’re just a lazy dirtbag like me, JB Fab makes a whole kit. It requires same shifter rail mod or replacement (I replaced mine, it was easier, and they ended up being really worn anyway.) I had to send my shifters back and have them shortened because they were way too long, they’re stainless or I would have just cut them off myself, but it only cost me shipping – JB’s customer service is just awesome. Here’s a little pic dump from my twin stick conversion. I used front dig (FWD) several times last summer and it was sure a game changer on several obstacles.

Before shortening (WAY too tall)

After

Feedback From Snoranger

If I ever twin stick a 205, My plan is to use this shifter setup from Speedway motors for $20…

Speedway motors economy shifter 91021950

Video

Links

https://www.therangerstation.com/forums/index.php?threads/ford-np205-twin-stick.176680/

https://www.speedwaymotors.com/Economy-Shifter,1928.html

Related Article:

About The Author

Justin '85_Ranger4x4' has been a member of TRS since 2002. Justin has a small farmstead in rural Iowa where he farms with vintage farm equipment and works on his 1985 Ford Ranger that he got his sophomore year of high school. But don't let that fool you. Justin has a Manufacturing Engineering degree with experience in R&D and automotive/ag/heavy truck part sales and decades of mechanical experience.