Introduction

This page discusses the different ways that you can increase the horsepower and performance of a Ford 2.8L V6 engine.

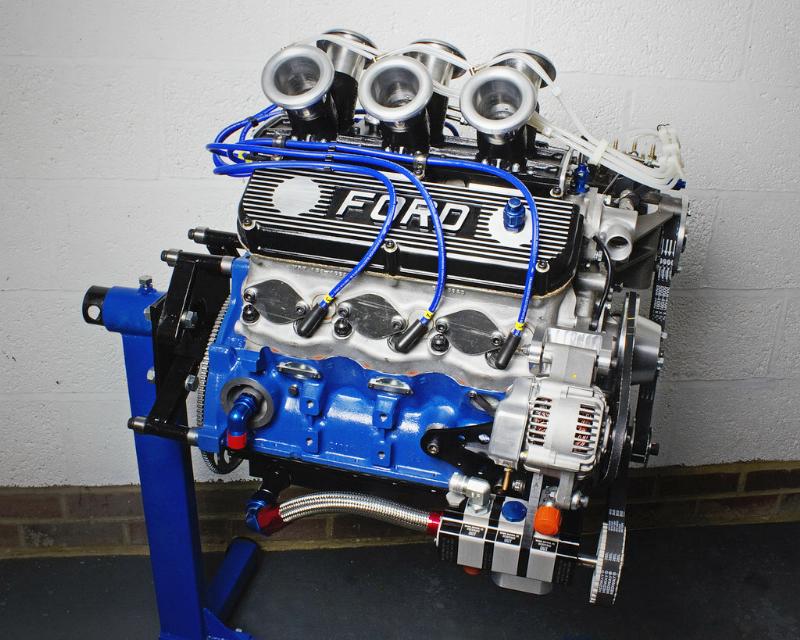

(Ford Cologne 2.8L with Westlake cylinder heads and throttle assembly)

The Ford Cologne 2.8L V6

The Ford Cologne 2.8L V6 is a 60° cast iron block V6 engine built by the Ford Motor Company in Cologne, Germany. The engine was used in a variety of Ford vehicles from 1974 until 1986

The 2.8L was used in:

- 1983-1985 Ford Ranger

- 1984-1985 Ford Bronco II

- 1986 Ford Aerostar (very rare)

- 1974-1978 Ford Mustang II

- 1979 Ford Mustang

- 1975-1979 Ford Pinto

- 1974-1977 Ford Capri (unsold ’77 models were sold in ’78)

Ford Ranger / Bronco II 2.8L vs Ford Mustang / Pinto 2.8L

The engine used in the 1983-1985 Ford Ranger and 1984-1985 Ford Bronco II differs from the engine used in the Ford Pinto, Ford Mustang II, and 1979 Ford Mustang.

Ignition

The car engines used either ignition points or a Duraspark ignition system. The 1974 Ford Mustang II used points but switched to the Duraspark for 1975. The Ranger and Bronco II use an EEC IV computer system / TFI ignition module, distributor and feedback carburetor. The TFI systems can be problematic, and many people choose to get rid of it and convert to a Duraspark ignition.

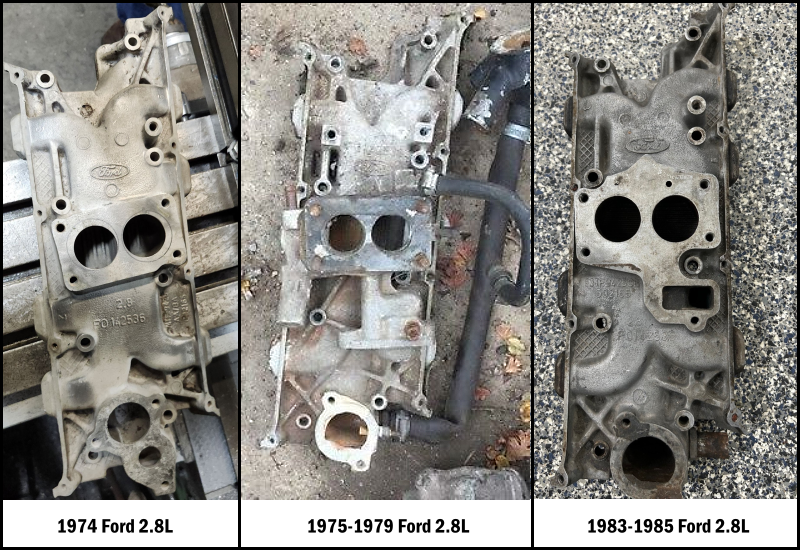

Intake Manifold

The Ford Ranger / Bronco II intake manifold had a taller plenum and slightly longer runners to improve torque. The car manifold had a short “pancake” style plenum.

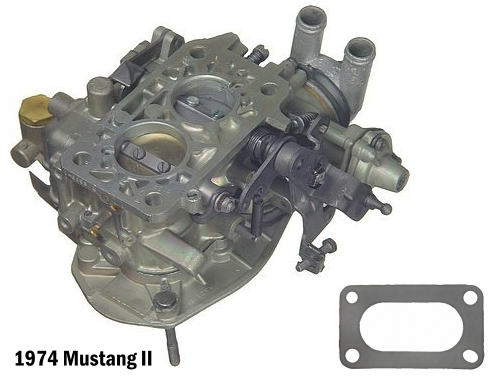

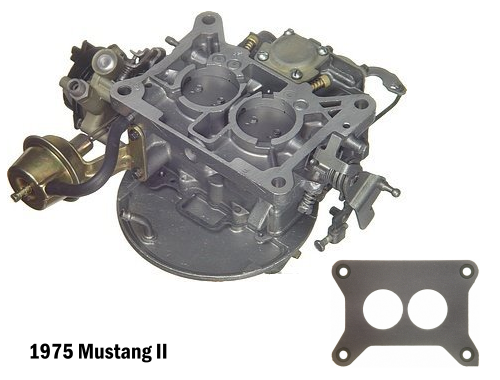

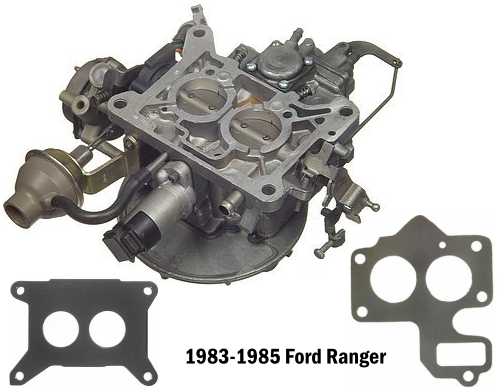

Carburetor

The Ford Ranger / Bronco II comes stock with the 2150A carburetor, which is computer controlled unlike the previous 2150 models; without a computer, the 2150A is basically useless. An easy performance add-on is a Holley 350, or 300cfm 2bbl carb and should bolt in place of your old one (it comes with either automatic or electric choke).

The Mustang II and pinto used a regular 2150 carburetor that doesn’t require computer feedback.

Cylinder Heads

The 2.8L engine came with two types of cylinder heads, a “non-emissions” head and a “smog” head. The non-emissions head that was available from late 1973 to mid-1975 is the more desirable of the two. The smog heads were available from mid-1975 to 1979 and from 1983-1986. The primary advantage of the early heads is that they lack the exhaust crossover passages used in the later smog heads. The result is that the exhaust ports in the early heads tend to flow slightly better than the later versions.

The reason for these additional exhaust passages was to increase the rate at which the intake manifold was heated, there-by reducing emissions and improving warmup in cold climates. The early engines used engine coolant to heat the intake manifold instead of hot exhaust gases. At any rate, the heads to have for a performance 2.8L engine are the early versions.

| Casting Number | Comments |

|---|---|

| 74TM | Non-Smog (Mustang II) |

| 75TM | Smog (Mustang II, Pinto) |

| 77TM | Smog (Mustang II, Mustang, Pinto) |

| 83TM | Smog (Ranger, Bronco II) |

Engine Block

The 2.8L did not use the same engine block from 1974-1986. Here are the two engine blocks used:

73TM6015AA – Often called the “automotive” block. While best known for its application in the Ford’s European Capri from 1974-1983, it was also used in the 1974-1978 Mustang II, 1979 Ford Mustang / Mercury Capri, and 1974-1977 Ford Capri.

83TM6015AA – Often called the “truck” block, since it was used in the US in the Ford Ranger and Bronco II. Apparently, it was also used in many Capris including the 2.8i. It is somewhat stronger than the earlier 2.8 block. This block has larger cam bearings than the “automotive” block.

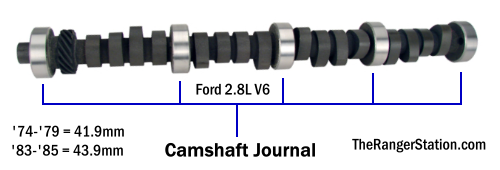

Camshaft Journal

The Ford 2.8 used in the Ranger & Bronco II have a 43.9mm camshaft journal.

The Ford 2.8 use in the Mustangs and Pintos have a smaller 41.9mm camshaft journal.

Oil Pan

The Ford Ranger / Bronco II uses a rear sump oil pan; the Mustang II 2.8 uses a front sump oil pan.

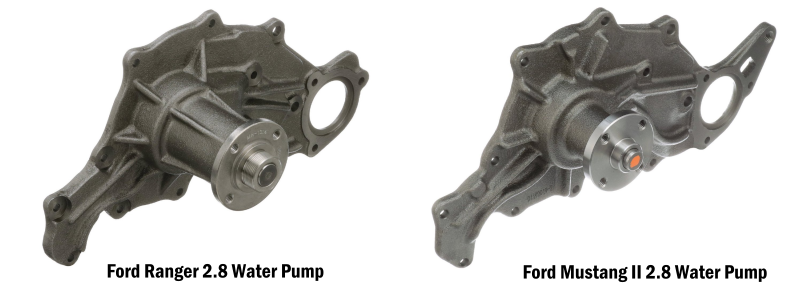

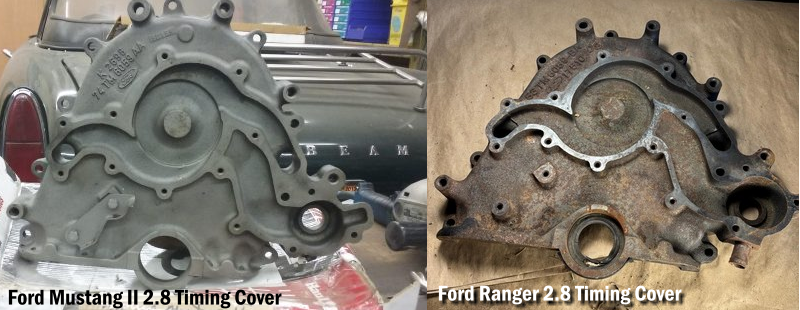

Water Pump / Timing Cover

The Ford Ranger / Bronco II 2.8 uses a different timing cover and water pump than the Ford Mustang II / Pinto 2.8. Use can see the differences in the casing (The Mustang II has an extension on it) and the Ford Ranger / Bronco II water pump reaches out about 1.5-inches further than the Mustang II pump.

Ford 2.8L Performance Upgrades

Ignition Module

If you’re wanting to maintain the stock ignition, I would at least switch to a Remote Mounted TFI Module with a heat sink and actually replace the TFI module with a Holley Accel 35369 TFI Ignition Module.

MSD offers wiring harnesses to simplify the installation of a MSD 6 series box on late model vehicles. The harnesses plug in between the ignition coil and the factory coil connector. Four wires with corresponding colors and matching connectors then connect directly to the MSD 6 wires. These harnesses reduce the installation time, reduce or eliminate cut wires, and allow you to quickly convert back to the factory ignition.

MSD-8874 Shown Above

The MSD to Ford TFI Coil Harness is designed to provide a splice-free and simple installation of an MSD Ignition Control to Ford vehicles equipped with a TFI Coil. On MSD 6 & 7 Series Ignitions all of the wires connect to the corresponding colored wires. MSD 7 Series Ignitions share the same color wires.

1. Disconnect the connector from the coil and connect it to the MSD PN 8874 Harness.

2. Connect the other end of the Harness to the Coil.

3. Connect the four wires of the Harness to the MSD Ignition Control.

Ignition Coil

MSD Blaster TFI coils will work with stock TFI ignition systems as well as MSD-equipped cars and trucks. Looking to get a little more output voltage from your Ford ignition system? Just bolt in one of these MSD Blaster TFI coils.

Duraspark Conversion

The better option would be to do a Duraspark Conversion and replace the EEC IV computer system / TFI Module. This is going to require finding a distributor from a 1975-1978 Mustang II, 1979 Mustang or 1975-1979 Ford Pinto. You’ll also need a Duraspark ignition module, coil, and a normal, non-feedback, 2-barrel carburetor.

Powerspark Conversion

If you can’t find the right distributor for a Duraspark conversion you can opt for an aftermarket Powerspark Distributor. The Powerspark distributor has a built-in ignition, so you don’t need the Duraspark ignition box, just a coil.

Intake Manifold

The 2.8L V-6 comes with a 2-bbl carburetor and manifold with a traditional round metal air filter container. Offenhauser offers a 6097DP 4-bbl Intake Manifold. The ignition system must be changed to earlier Duraspark vacuum advance unit eliminating the EEC-IV computer / TFI and pollution equipment. You can use the distributor, ignition module and coil from a 1975-1978 Ford Mustang / Pinto. The Offenhauser Intake does not have an EGR setup.

The Offenhauser intake manifold offers very good low and midrange power and torque characteristics. The patented Dual Port design actually separates the primary and secondary carburetor circuits into two individual (relatively small) passages. As a result of this unique arrangement, a high mixture velocity is maintained in both the primary and secondary passages of the manifold thus creating a wider torque curve than would normally result if a conventional manifold were used. An added benefit of the dual port concept is that carburetors can actually be a bit too large and still perform well. In fact, Holley 465cfm carburetors are frequently used in racing V6’s with little to no loss in low and midrange power.

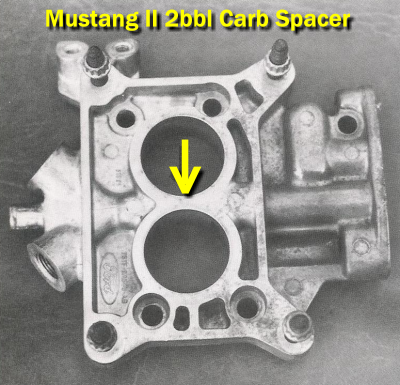

The lower half of the Offenhauser intake manifold is almost a carbon copy of a stock intake manifold except that the plenum divider has been relieved in the middle. See the yellow arrow in the image below.

The upper portion of the Offenhauser intake shows an empty separate secondary manifold channel. This, in essence, creates a manifold inside a manifold.

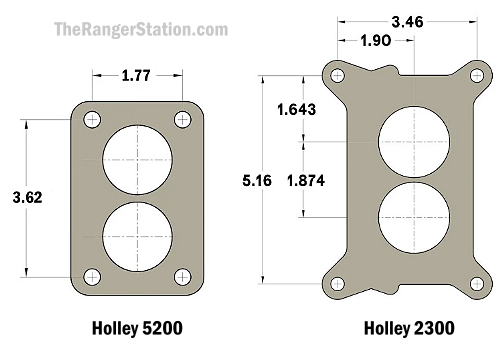

Carburetor

Two-Barrel Performance Carburetors:

Ideally, a good two-barrel carburetor would be easily available, inexpensive, very tuneable, easy to service, and would provide exceptional performance. The Holley Model 2300 (0-7448), 350cfm two-barrel performance carburetor meets all of these criteria with ease. This carburetor is essentially the front half of a standard Holley (4150/4160) four-barrel carburetor. Therefore, most of the tuning tips applicable to Holley four-barrels also apply to this one. This carburetor should be used in all performance applications that require a two-barrel manifold combination. Interestingly, this carburetor is so user-friendly, it makes a very desirable replacement to the stock factory carbs.

Holley 0-7448 Two-Barrel Carburetor

NOTE: The Holley 0-7448 Two-Barrel Carburetor has been discontinued, and Holley recommends the 0-7448SA as a replacement.

When restricted to the use of a two-barrel carb, you should remember a few rules of thumb to get the most from your investment. First, resist the urge to “over-cam” the engine. Two-barrel carbs will respond better to relatively short duration cams with fast lift rates. Look for something in the 210-225 degree duration (@ 0.050in) range. Second, install an open plenum spacer under the carburetor. This spacer should be a minimum of 3/4in thick. An inexpensive alternative to making a spacer of this type is to use a spacer from a 1976 Ford Mustang II or Capri that was fitted with the Motorcraft carburetor.

Simply mill out the divider between the two throttle bores on the plate and seal off any remaining holes once dedicated to emissions devices. Install the spacer using new gaskets on each side. These gaskets should also have the material between the throttle holes removed. Once you have completed these steps, simply follow the tuning suggestions that apply to the primary side of the Holley four-barrel carburetor.

You may want to try the Trans-Dapt 2-Barrel Carb Spacer #2135.

Trans-Dapt 2-Barrel Carb Spacer #2135

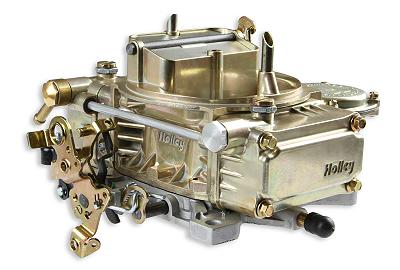

The Holley 390cfm Four-Barrel:

When Offenhauser introduced its Dual-Port four-barrel manifold for the Ford V6, it exposed Ford V6 enthusiasts to an entirely new performance carburetor option. That option was the 390cfm Holley four-barrel carburetor. The Holley four-barrel is without question one of the most versatile, successful, and tunable carburetors in the world.

For performance Ford V6 applications, the best Holley four-barrel carburetor available is the 0-8007, 390cfm, model 4160. Although other 390cfm carbs are available, the 0-8007 requires the least amount of modification to provide optimum performance. The 0-8007 will accept most of the Holley “tick” parts such as center hung floats, secondary metering blocks, 50cc accelerator pumps, and so on. It works very well with increased compression ratios and “big” camshafts. In fact, the 390 four-barrel easily accommodates engines capable of producing in excess of 220 horsepower. The Holley 390cfm carburetor/Offenhauser Dual-Port intake manifold combination is, without question, the most effective readily available intake system for a high-performance Ford V6.

Holley 0-8007 4160 Four-Barrel Carburetor

Fuel Injection

Ford actually fuel injected the 2.8L’s sold in Europe with the mechanical Bosch K-Jetronic injection and later Jetronic electronic injection (EEC/L-Jetronic variants) but did not fuel inject the ones sold in North America.

I know of three ways that people have adding fuel injection to the Ford 2.8L V6:

2.8L Chevy TBI Swap on to Ford 2.8 (Uses the TBI from a Chevy 2.8)

Fuel Injection For Your 2.8L Ford Ranger / Bronco II (Uses the CFI (Central Fuel Injection) from a Ford 3.8

Holley Sniper EFI 2300 Conversion

Camshafts

Comp Cams offers three different camshafts for the Ford 2.8L (2800):

38-101-4: Solid: Good Cam for OEM replacement or rebuild. Low RPM torque with good economy. Very Smooth idle.

38-240-4: Solid: Performance with economy, power increase in low-mid RPM range. Smooth idle.

38-241-4: Moderate performance Camshaft. Strong in mid-range RPM. Noticeable idle.

Racer Walsh offers two different camshafts for the Ford 2.8L

RWA 6411 stage #1 Camshaft. The stage 1 cam gives a smooth idle as well as a boost in low to mid-range power, without sacrificing fuel economy.

RWA 6412 stage #2 camshaft. The stage #2 V-6 camshaft for the 2.6L/2.8L engines offer a significant power increase from mid-range to top end performance. The Stage #2 camshaft is a street / competition grind. We recommend a slightly higher than stock stall on the converter if an automatic transmission is used.

When ordering a Racer Walsh camshaft, they will want to know the year of your engine, so they know which camshaft journal size you need.

Comp Cams and Racer Walsh also carry pushrods and lifters.

Timing Gear Set

New timing gears are offered by both Comp Cams (3236CPG) and Racer Walsh (RWA 6548). These are an all-metal design and will outlast the stock fiber type timing gears. These are designed as a stock replacement upgrade.

Pistons

Racer Walsh sells a set of Wiseco Ford 2.8L 9-1 Pistons. The stock 2.8 compression ratio is 8.7:1.

Stroker Kit

Tom Morana sells a Stroker Kit. A Stroker Kit is forged replacement engine components (forged custom pistons/compression of choice, forged connecting rods, performance piston rings, rod & main bearings, and Stroker crankshaft), which is much stronger than stock internals, and a good solid foundation, for those who intend on using boost e.g. Nos, turbo charging or supercharging, or N/A. This Stroker Kit will take you from 2.8-3.2 for 3–40 hp gains depending on compression ratio, cam etc. $3,500. USD.

**Your crankshaft core IS REQUIRED as an exchange for the Stroker Crank** Special shipping instructions needed before shipping. We pay for your core return shipping.

Headers

Hedman used to offer header P/N 89380 (painted) and 89386 (coated) for the Ford Ranger / Bronco II 2.8L 2WD, but they are no longer available. I couldn’t find a photo of them. If anyone has a photo, please send it to me so I can share so people know what to look for at swap meets.

Turbocharger

In the late 1970’s and 1980’s there were companies such as AK Miller Enterprises and Spearco Performance Products that made supercharger kits for the Ford 2.8L. Today people may wonder if they can turbocharger the Ford 2.8L, but there was a time when it was a popular modification. It was even more popular to turbocharge the Ford 2.8L in Europe. In fact, you could buy vehicles that had Ford 2.8L engines that were turbocharged by Turbo Technics. Those Turbo Technics 2.8L Fords made anywhere from 200-320 horsepower and came with either a single or twin turbos.

Today people still turbocharge their 2.8L’s, but there aren’t any complete kits for them. You have to fabricate your own.

Racer Walsh

Racer Walsh |

|

| Here is a list of parts listed on their website. You may need search by the Part Number. | |

| OFFY 4bbl / Holley 390 cfm – We recommend this manifold carb combination for street driving. A popular choice for the 2.8 Bronco II / Ranger. It will perform well on a stock or modified engine. It is easy bolt-on horsepower that still gives good gas mileage. Bronco II & Ranger require a special thermostat / waterneck housing # 6278. | |

| Part Number | Description |

| 6110 | Offy 4bbl Manifold |

| 6239 | 390cfm 4bbl Carb |

| 6278 | Thermostat Housing |

| 2.8 V6 Cams – Stage 1 cam gives a smooth idle and low and mid range power boost without sacrificing economy. Stage 2 cam is a street/competition grind. Higher lift and increased overlap give a rougher idle. Good midrange power increase. Specify engine year when ordering: ’72-’83 had smaller cam journal size than later years. | |

| Part Number | Description |

| 6411 | Stage 1 Cam (260 DUR 425″ LIFT) |

| 6412 | Stage 2 Cam (264 DUR 448″ LIFT) |

| 6477 | Valve Spring Set |

| 6449 | Retainer Set Steel |

| 6489 | Pushrod Set (Stock Replacement) |

| 6487 | Lifter Set (Stock Replacement) |

| Engine Gasket, Oil Pump & Bearings – Complete gasket set for the 2.8 engine. Hi volume oil pump and Clevite bearings. | |

| Part Number | Description |

| 6592 | Engine Gasket Set |

| 1765C | HI Volume Oil Pump |

| 6520 | Rod Bearing Set V6 |

| 6528 | Main Bearing Set V6 |

| 1570K | ARP Rod Bolts |

| Forged Pistons 2.8 – 9-1 forged piston set for the 2800 V6 engine. We stock .030″ overbore. Priced per set of 6, includes wrist pins. | |

| Part Number | Description |

| 6498 | Forged Pistons |

| 6499 | Pistons Rings |

| Metal Timing Gears – Metal timing gears are more durable than the stock fiber type timing gears. | |

| Part Number | Description |

| 6548 | Timing Gears V6 |

Miscellaneous Parts

Miscellaneous Parts List |

||

|

Part Number |

Brand |

Description |

| CL38-101-4 | Competition Cams | Good cam for OEM replacement or rebuild. Low RPM torque with good economy. |

| CL38-240-4 | Competition Cams | Performance with economy, power increase in low-mid RPM range. See note 2. (Good For Auto) |

| CL38-241-4 | Competition Cams | Great for towing and highway use. Strong torque and power increases. (Good For Manual) |

| 6846 | Edelbrock | Bolt on headers for 2 and 4 wheel drive Ranger / Bronco II |

| 0FF-6097-DP | Offenhauser | 4-Barrel intake manifold. |

| 0-7448 | Holley | 350 cfm 2-barrel carb. |

| 0-8007 | Holley | 390 cfm 4-barrel carb. |

| M-12199-C301 | Ford Motorsport | Ford Extra Performance Ignition (for non-computer controlled conversion) |

| M-12029-A302 | Ford Motorsport | High Energy Coil (for non-computer controlled conversion) |

| M-12071-A301 | Ford Motorsport | Wiring Harness (for non-computer controlled conversion) |

| M-12449-A600 | Ford Motorsport | RPM Programming Chips 6000-6800 RPM for Ford Extra Performance Ignition. |

| NRD482691 | NAPA Auto Parts | 979 Vacuum advance distributor (for non-computer controlled conversion) |

| MPEFA136SB | NAPA Auto Parts | Ignition Cap for 79 Vacuum advance distributor. |

| ECHFA139 | NAPA Auto Parts | Ignition Cap Adapter Collar for 79 Vacuum advance distributor. |

| MPEFA159SB | NAPA Auto Parts | Ignition Rotor for 79 Vacuum advance distributor (Non-Bosh) |

| Note – The Comp Cam ……part # CL38-241-4 should be used with a manual transmission. The RPM range of this Cam will really hurt an A4LD on takeoff. The torque converters/stall speed is outside of its range. You really want to generate as much low-end power as you can with a manual transmission because you can vary the RPM range when you let out the clutch.

Note – The CL in the part number can be replaced with SK if you want timing gears included with the cam and lifter kit. |

||

200 Horsepower Inspiration

Byron Froelich was the man who built the powerplants for Stroppe’s trucks. He built Ford 2.8L V6’s that produced over 200-horsepower using 11.7:1 pistons, 289 Ford V8 piston rods, modified V8 lifters, a stock intake manifold modified for a four-barrel carburetor, and a reground camshaft. To learn more, check out 200 Horsepower From Ford 2.8 Liter V6.

Related Articles

Ford Ranger / Bronco II 2.8L V6 Engines

2.8L Chevy TBI Swap on to Ford 2.8

Fuel Injection For Your 2.8L Ford Ranger / Bronco II

200 Horsepower From Ford 2.8 Liter V6

About The Author

Jim Oaks is the founder of TheRangerStation.com, the longest-running Ford Ranger resource online since 1999. With over 25 years of hands-on experience building and modifying Ford Rangers — including magazine-featured builds like Project Transformer — Jim has become one of the most trusted authorities in the Ford Ranger off-road and enthusiast space.

Since launching TheRangerStation.com, Jim has documented thousands of real-world Ranger builds, technical repairs, drivetrain swaps, suspension modifications, and off-road adventures contributed by owners worldwide. TheRangerStation.com has been referenced in print, video and online by enthusiasts, mechanics, and off-road builders looking for practical, and experience-based information.