Index:

Transfer Case Difficult To Shift Into Desired Range

Transfer Case Noisy In All Gears

Transfer Case Noisy Or Jumps Out Of 4×4 Low Range

Lubricant Leaks From Vent Or Output Shaft Seals

Troubleshooting 1995 & Newer Electric Shift Transfer Cases

Diagnosing 1994 & Older Electric Shift Transfer Cases

Cleaning & Testing The Shift Motor (1994 & Older)

Cleaning The Shift Motor 1995 & Newer

Intermittent Or No 4Low in 1995 Or Newer Systems

Basic Problems:

Transfer Case Difficult To Shift Into Desired Range:

1. Speed may be too great to permit engagement. Stop the vehicle and shift into the desired range.

2. Shift linkage loose, bent or binding. Check the linkage for damage or wear and replace or lubricate as necessary.

3. If the vehicle has been driven on a paved surface for some time, the driveline torque can make shifting difficult. Stop and shift into 2-wheel drive on paved or hard surfaces.

4. Insufficient or incorrect grade of lubricant. Drain and refill the transfer case with the specified lubricant.

5. Worn or damaged internal components. Disassembly and overhaul of the transfer case may be necessary.

Transfer Case Noisy In All Gears:

Insufficient or incorrect grade of lubricant. Drain and refill

Transfer Case Noisy Or Jumps Out Of 4×4 Low Range:

1. Transfer case not fully engaged. Stop the vehicle, shift into Neutral and then engage 4L.

2. Shift linkage loose, worn or binding. Tighten, repair or lubricate linkage as necessary.

3. Shift fork cracked, inserts worn or fork binding on the rail. Disassemble and repair as necessary.

4. Inspect bushings on linkage and replace as necessary.

Lubricant Leaks From Vent Or Output Shaft Seals:

1. Transfer case is overfilled. Drain to the proper level.

2. Vent is clogged or jammed closed. Clear or replace the vent. If using extended vent tubes, make sure the tube isn’t sagging and allowing fluid to collect and not drain back in to the case.

3. Output shaft seal incorrectly installed or damaged. Replace the seal and check contact surfaces for nicks and scoring.

Trouble Shooting:

1995 & Newer Transfer Cases:

This problem turned out to be the electronic 4WD Control Module behind the passenger side kick panel. The box is easy to replace and has 4X4CM on it.

Symptoms:

1) When starting vehicle, the “4WD” and “4WD LOW” lights on dash never illuminate.

2) After turning 4WD switch (knob on dash) there is no response at all, 4WD light on dash never illuminates and no clicking.

3) 4WD will not engage.

Normal operation would be:

1) When starting vehicle, the “4WD” and “4WD LOW” lights on dash momentarily illuminate right after starter engages and key is released to the “run” position.

2) After turning 4WD switch (knob on dash), 4WD light on dash illuminates and clicking is heard.

3) 4WD engages.

4) By the way, the “4WD” and “4WD LOW” lights aren’t supposed to illuminate when the key is turned to the point right before the starter engages. They only momentarily illuminate AFTER the truck is started. All the other dash lights light BEFORE starter engagement, but not the 4WD for some reason.

Before changing out the Control Module, I did this (so I didn’t waste $100 on a box I didn’t need):

1) Checked the electrical grounding lugs near the module with a meter.

2) Checked any fuse that said anything remotely about 4WD or powertrain.

3) Checked ALL fuses I could easily check. TIP: The ones that are smaller in size have 2 very small metal points to check with a meter without needing to remove the fuse, this saved a ton of time.

4) Checked the relay under the hood that said something about powertrain control module or PCM (I changed it with the one next to it for the blower), they seemed to be rated the same from what I could tell. I swapped them and tried the 4WD, no change.

5) I had a diode setting on my meter; I checked the powertrain control module diode.

When installing the Control Module, I disconnected the negative battery terminal first. Also, I’ve had past problems with another vehicle and the loss of the computer memory for idle control. Granted, I don’t know if this applies to the Ranger, but I played it safe so I didn’t have to redo it. So to “relearn idle” I did this:

1) Park vehicle in a place I could let it run for 10 min without moving.

2) Let engine cool several hours to attain a “cold engine”.

3) Disconnect battery negative terminal.

4) Changed CM.

5) Reconnect battery negative terminal.

6) Started vehicle, and let idle in park for 10 min on cold engine to relearn cold idle. Absolutely DO NOT drive or rev engine at all.

Then I put the 4WD on and drove crazily around the neighborhood on the snowy roads. Fixed! Whoo Hoo! Now I can plow my driveway again and save my back! Super Whoo Hoo!

I got the 4WD Control Module at www.directfordparts.com for $98 (plus shipping). The local Ford dealer wanted $185. The local dealer also wanted $80 to diagnose the problem. I had no way to test my CM, but took a gamble and it paid off. Whew!

4×4 System Diagnosis – 1994 And Older (Submitted by Chris1044):

I made the specifics of this apply to a 1994 Ranger with a BW1354 case, but I’m sure that the basic concepts can be applied to other years.

I can’t cover every practical situation that you’ll encounter with the 4×4 not working. This is written to be a guide for most situations……its going to be long, and assumes that you can:

1) use a test light to check fuses and

2) use a volt meter to check for power/grounds/resistance in different circuits.

CAUTION: DO NOT jam a test light or volt meter lead into any connector. You’ll ruin that connector or ruin its ability to maintain a solid connection with the other pin. Don’t do this ever on any connector period. Go to Wal-Mart, go to the sewing department and pick up a pack of small T-pins – they work great for this sort of thing or back probing connectors.

If you can’t use a volt meter, you can still do some basics – just don’t expect to find something like a corroded wire at some connection that’s causing your 4×4 system failure.

I also can’t be held responsible for stupid on your part. If you jack only your front two tires up, put the truck in 4×4, and try to see if the front wheels are spinning….you get my point….

First, are you sure that you don’t have 4×4? This article is going to cover the electrical shifting system and will not touch on your 4×4 hubs and how to fix them.

Before you get in over your head, and realize you’ve got shitty hubs and not a bad 4×4 shift system, do yourself a favor and put the truck up on jack stands (all 4 tires off the ground). Shift the truck into 4×4, and with the motor running put the trans into drive. Let out on the brake, and let the truck idle in drive…..check to see if both drive shafts are turning. If they are, yet you’ve got no front wheels spinning, you’ve got a hub issue. If one is spinning it’s because you’ve got an open diff……

Assuming that your front drive shaft is not spinning, you’ve got a 4×4 engagement problem…….now you’ve got to do some diagnostics.

Diagnostics:

1. Check to make sure all fuses for the system are good. There are two fuses that supply power to your 4×4 shift system – one located under the hood, the other under the dash. The under fuse is a 20 amp maxi fuse, the under dash fuse is a 15 amp ATO fuse – on the 94 rangers its located in the fuse position 7.

a. If they’re good, go to the next step,

b. If they’re bad, you’ve got a short somewhere in the system. Try to replace the fuse, and see what happens. If it blows, you’ve got something shorted to ground in the circuit. If you know how to use a volt meter, you should know how to find a short in the circuit, and will need a wiring diagram to do so.

2. If all the fuses are good, the next step is to run the 4×4 module self diagnostic. The 4×4 module is located behind the driver’s side rear jump seat on super-cab models, but as far as the other locations I don’t really know. This module will have three connectors going to it – one will be a pig tail, the other two will be located on the right side of it (side towards the front of the truck). These two connectors must be removed to diagnose the module. With the key in the off position, remove these two connectors from the module. Next, turn the key on with the engine off. On top of the module is a white rectangular button located next to a red LED….push the button and watch the LED.

a. If it flashes, this indicates the module is working properly. Go to the next step

b. If it lights up and stays on, it indicates that the module is likely bad. If nothing happens it means the module is either bad, or has no ground/power. In either of these instances power and ground should be verified before scrapping a 4×4 module.

c. The 4×4 module receives its power/ground through the 8 pin pigtail connector.

1. Pin Position 1 = Open, no wire

2. Position 2 = Solid Black = Ground

3. Position 3 = Orange/Black = Logic Ground

4. Position 4 = Orange = Transfer Case Motor Control (Clockwise) 2H-4H-4L

5. Position 5 (across from position 4) = Yellow = Transfer Case Motor Control (Counterclockwise) 4L-4H-2H

6. Position 6 = Brown = Electromagnetic Clutch (Feed)

7. Position 7 = White/Purple = Ignition Run and Crank (Start) Feed (Fused)

8. Position 8 = Dark Green/Light Green = 20A Maxi-Fuse in Power Network Box (under hood fuse)

3. With the two connectors still unplugged from the module, the next step is to verify the 4×4 dash switch input. Take the 5 wire connector, the one with the grey connector color, and check the following:

a. Connect an ohmmeter between terminals 1 (White/Light blue wire) and 2 (Dark Blue wire). Then depress the 4×4 (2H-4H) switch. The ohmmeter should indicate a low resistance value (less than 50 ohms) while the switch is being depressed. If this occurs, the switch feed to and from the module is good.

b. Connect an ohmmeter between terminals 1 and 3 (orange/light blue wire). Then depress the LOW RANGE switch. The ohmmeter should indicate a low resistance value (less than 50 ohms) while the switch is being depressed. Again, if this occurs, the 4 low switch is good.

c. Connect a test lead between terminal 4 (brown/white wire) and ground. Turn the ignition switch to RUN and observe the indicator lights. The LOW RANGE light in the instrument panel and LOW RANGE indicator light on the switch should illuminate. This indicates the 4×4 lo switch/dash lights are good.

d. Connect a test lead between terminal number 5 (grey wire) and ground. Turn the ignition switch to RUN and observe the indicator lights. The 4×4 light in the instrument panel and 4×4 light on the switch should illuminate. This indicates the 4×4 hi lights/dash lights are good.

e. If any of these tests fail, you will have to check the wires from the module to the back of the switch for continuity. This is done easily by removing the dash switch and connecting an ohmmeter between the same color wires, with one lead at the module and the other at the switch. A resistance value of 10 ohms or less is good, any more indicates excessive circuit resistance. If all 5 wires have low resistance between the switch and module, the switch is bad and must be replaced.

4. The next step will check the circuitry to the shift motor. Your shift motor must be hooked up for this to work. Grab the 8 wire connector that is unplugged from the 4×4 module. It will be tan in color. Check the following:

a. Connect an ohmmeter between terminal 1 (red/light blue for manual trans vehicles, red/white for auto trans vehicles) and ground. On a vehicle equipped with a manual transmission, depress the clutch pedal and observe the ohmmeter. The ohmmeter should indicate a low resistance (less than 50 ohms) while the clutch pedal is being depressed. If the vehicle is equipped with an automatic transmission, shift the transmission into NEUTRAL and observe the ohmmeter. The ohmmeter should indicate a low resistance (less than 50 ohms) while the transmission selector lever is in the NEUTRAL position. This ensures that the Park/Neutral switch or Clutch pedal switch is good (needed for 4 lo shifts)

b. Connect an ohmmeter between terminals 2 (light green) and 3 (light blue). The ohmmeter should indicate a low resistance reading (235-470 ohms). This will check the continuity of the speed sensor that is located in the transfer case. The speed sensor picks up the rotating speed of the transfer case rear output shaft from two notches that are cut in opposite sides of the outer ring of the clutch housing.

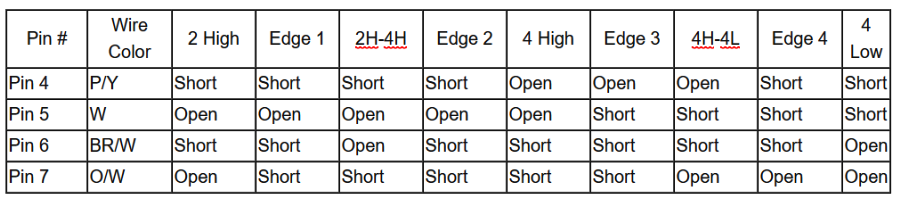

c. Connect an ohmmeter between terminal 8 (yellow/white) and terminals 4 (violet), 5 (white), 6 (brown/white) and 7 (orange/white), respectively. Refer to the following chart for the appropriate ohmmeter readings in each transfer case position.

Ohmmeter Readings For Shift Motor Position Sensor:

Pin 8 Y/W To: Transfer Case Motor Position

NOTE: Edge positions and Mid-Shift positions are valid motor codes that the module will respond to; however, any motor found in one of these positions should be replaced/torn apart and cleaned/inspected to prevent the overshooting of shift points.

SHORT is a “low” resistance reading on the ohmmeter (zero ohms).

OPEN is a “high” resistance reading on the ohmmeter (infinity).

5. Up to now, the following should have been verified:

i. All fuses are good

ii. The 4×4 module tested ok, and has power/ground (make sure the pigtail connector isn’t corroded – is common among rust belt trucks)

iii. The 4×4 switch tested ok

iv. The shift motor circuitry tested ok

b. With the key off, reconnect the two connectors. Make sure the key is off.

c. The next step is to verify that the module is supplying voltage to the shift motor. To do this, you’ll either need a second person or long volt meter leads. Crawl under the truck. Find the connector that connects to the shift motor. Leave it connected. Back probe the solid orange wire through the connector located on the shift motor side. You are essentially checking for voltage at this pin to ensure that it is getting voltage, and that the connector is good. Next, turn the key to run and push the 4×4 switch. You should see 12 volts on the volt meter. If not, ensure that the volt meter has a good ground and try again.

i. If you’ve got a 12 volt signal, go to the next step (D)

ii. If you’ve got nothing still, go to step 6

d. If you have a 12 volt signal, the next thing to do is verify that the motor has a good ground as well. Back probe the solid orange wire on the connector as well. Again, check for a 12 volt signal using the yellow wire. This ensures that the module is grounding the other side of the motor, allowing for current to flow through the motor. If the shift motor still doesn’t work (you can’t hear/feel it spin) then it’s probably bad. You can remove it from the transfer case and make sure you can spin the transfer case manually using a pair of pliers. If you can, then it’s a good bet the motor is bad. If you can’t, you’ve got other issues and the t-case probably needs some internal repair…..the shift motor may be alright after all, and the major (internal) issue must be repaired first.

i. If you didn’t receive a 12 volt signal, then the module isn’t grounding the motor for some reason, and could be bad. Continuity from the orange/yellow wires at the shift motor connector to the 8 wire pig-tail connector from the module must be checked.

6. If in step five you had no power signal, even when you grounded the volt meter to something other than the module itself, you need to 1) make sure the wires have continuity between the 4×4 module and shift motor, and 2) make sure that the module is sending a 12v supply to the 4×4 switch. To verify issue 1, see part d-I in step 5. To verify issue 2:

a. With all connectors plugged into the module, back probe the dark blue wire (terminal 2) on the 5 pin gray connector – the one on the lower right side of the module. Make sure you DO NOT ground your back probe out while doing this. With this pin back probed, turn the key on. Check for a 12 volt signal there while pushing the 4×4 switch. If you have 12 volts there, your module is sending a 12 volt supply to the 4×4 switch.

i. If no voltage is present there, turn the key off and back probe terminal 1 (white/light blue) on the same connector. Again, it is more crucial here that this is not grounded. If you ground this pin out with the key on, even for 1/16th of a second, your module could be ruined. Now that you’ve ensured your back probe is not and cannot be grounded out, check for voltage by simply turning the key on.

1. If you have voltage here, but did not in part 6a you must verify continuity between the module and 4×4 switch – refer to step 3.

2. If you have no voltage here, make sure the module has power and ground. If it does, it’s probably bad.

If you can check all that stuff, yet still can’t figure out what is going on with your system, post up. That should be a fairly decent start on system diagnosis, and I’ll bet completing those steps will tell you what is wrong with your system. Again, there could be some weird issue, and you’ll have to make a post for more info.

Cleaning & Testing The Shift Motor (1994 & Older):

Four bolts hold on the weight that is used as a vibration dampener, and four bolts hold on the shift motor. Two of these bolts attach a bracket that secures the electrical connector as well as holding a sensor in place. There is silicone sealant used between the shift motor and the t-case body, so a little gentle prying might be in order.

There should be a yellow and an orange wire in the motor harness that are a bit larger gauge wire than the rest. Those are the motor power leads. If you apply voltage directly to those wires the motor should spin.

All 1350 and 1354 motors should be the same thru 1994. The 1995 and newer motors (with the blue covers) are different.

The sensor contacts are under the round cover on the back.

Warning: Be sure to mark how the cover was positioned before you take it off, it is not indexed.

With the shift motor apart, lightly sand the area where the contacts (things held back by springs) rub on the shaft to make sure they’re getting good contact.

If you’re just getting relay clicking, try loosening the torx screws and spinning the contact cover about 1/8 inch then tightening it back down. If it doesn’t work, move it 1/8 inch in the other direction. That helps the contacts find a new position on the plate, and also get them back on track if the rubber stopper is smashed, or totally disintegrated.

Cleaning The Shift Motor (1995 & Newer) (Submitted by roxy 33):

I don’t have too many pics, but they’re not really needed. Here’s what I did:

First, I tried all the fix ideas on the site including the shift motor rebuild and it still did not work. (still got the repeated clicking noise followed by the flashing lights) so I felt I had nothing to lose by tearing open the blue cap. I used a small flathead screwdriver to break away the tapered plastic seal (not too much, just enough to separate the two halves). Once separated, pull the contact disk out and you will find the worn spots where it has been in the 2 hi position for most of the trucks life.

Take a Dremmel tool or a file and smooth out the havoc you caused with your screw diver on the housing. Clean all the contact points with alcohol and Q-tips. Use light pressure with your small flathead screwdriver and bend all four drag fingers back into the position where they will make firm contact with the position sensor disk, but use care not to over do it. If you do, the fingers will dig into the disk, killing the fingers and making deeper grooves that caused the problem in the first place. Use good quality dielectric grease and lubricate the disk and fingers. Put the wheel back into the cup trying to keep it in the 2 hi position,( not too important though, since your shift motor took a dump in 2 hi the blue cap can only be put back on the same way), put a light coat of grease on the rubber o-rings that seal the cap and put the top back on. I used a few drops of super glue to hold it in place during the re install. Put it all back together and throw it back in to your truck. Hopefully this will fix your problem. My T-case has worked flawlessly for quite some time after doing this and I’m baffled why no one else has tried it yet. Good luck and let me know how it works.

If your 4hi and 4lo light come on flashing 6 times every 2 minutes check the 20A fuse under the hood in the power distribution box.

Intermittent (or no) 4-LO on 1995 & Newer Systems (2HI-4HI & back, fine) (submitted by rich)

Pulled radio for access. Disconnected and tested 4WD switch for resistance in each position. Disconnected GEM in dash, test several wires for continuity and voltage, disconnected and tested “T-case shift relay module” behind GEM. Relay module was supposed to show 80-140 ohms between two pins, showed zero.

Installed new module, reconnected 4WD switch and everything worked.

Other Links:

Servicing A Transfer Case Shift Motor

Rebuilding A Transfer Case Shift Motor