NOTE: This process will work on other engines.

Valve Seals –The 2.8L’s are known to burn oil and smoke when they get high mileage. They use a rubber valve seal that deteriorates and leaks oil into the cylinder. This can be fixed by pulling the valve covers off, removing the spark plug and filling the cylinder with compressed air (Need Special Fitting), and then removing the valve spring and replacing the seal (The air keeps the valve from dropping in to the cylinder). This should be repeated for each valve and then the valve lash reset when complete. This is a cheap and easy repair.

Tools & Parts Needed:

Air Compressor

Air Valve Holder (Air Adapter)

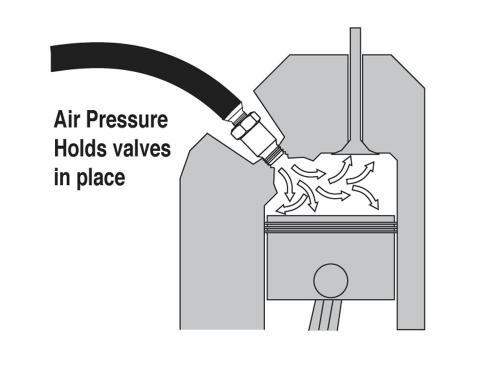

The Ford Ranger 2.8 & 4.0 OHV engines have a 14mm spark plug hole. There are fitting that will screw in to the spark plug hole to allow you to hook an air compressor hose up to the cylinder. The compressed air will hold the valves closed so that they don’t fall in to the engine when you remove the valve spring. You can either buy an Air Adapter and attach a compressor hose to it, or buy an Air Adapter With A Hose and air compressor fitting already attached.

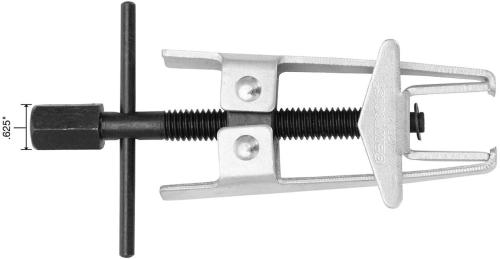

Valve Spring Compressor

New Valve Seals

Procedure:

1) Remove valve cover.

2) Remove applicable sparkplug wire and plug.

3) Remove rocker arm shaft stand attaching bolts by loosening the bolts two turns at a time, in sequence (from the end of shaft to middle shaft).

4) Lift off the rocker arm and shaft assembly and the oil baffle.

5) Remove both the valve push rods from the cylinder being serviced.

6) Install an air line with an adapter in the spark plug hole and apply pressure to hold the valve(s) in the closed position. Failure to hold the valve(s) closed is an indication of valve seat damage and requires removal of the cylinder head.

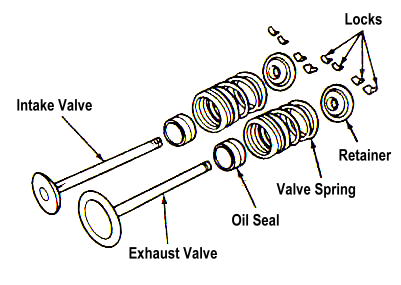

7) In stall the Valve Spring Compressor tool, compress the valve springs and remove the retainer locks, spring retainer and valve spring.

8) Remove and discard the valve stem seal.

9) If air pressure has forced the piston to the bottom of the cylinder, any removal of air pressure will allow the valve(s) to fall into the cylinder. A rubber band wrapped around the end of the valve stem will prevent this condition and will still allow enough travel to check the valve for binds.

10) Inspect the valve stem for damage. Rotate the valve and check the valve stem tip for eccentric movement during rotation. Move the valve up and down through normal travel in the valve guide and check the stem for binds.

11) If the valve condition proves satisfactory, lubricate the valve stem with engine oil. Hold the valve in the closed position and apply air pressure within the cylinder.

12) Install a new valve stem seal. Place the spring in position over the valves and install the valve spring retainer. Compress the valve spring and install the valve spring compressor tools.

13) Lubricate the push rod ends and install the pushrod. Lubricate the tip of the valve stem and to both ends of the rocker arm.

If you don’t have compressed air available to keep the valves closed to change the seals. An old mechanics trick is to take a rope of about 1/4″ diameter and feed it into the spark plug hole. Manually turn the engine until the piston pushes the rope up against the valves keeping them closed. Do not use the starter for this application. Turn the engine in the opposite direction to release the rope.