Submitted by: Ranger44

Difficulty: 6 out of 10.

Spark plugs used and recommended by FORD:

The driver’s side is pretty much straight forward, you can get at it through the top.

Use a pair of pliers or spark plug pliers to remove the plug wires from the 1st spark plug. It’s best to remove one plug and wire at a time. That way nothing gets mixed up and you can ensure everything is routed the same way it was removed.

Use a 5/8 spark plug socket to remove the first plug (cylinder #4).

Be sure to check and see that the spark plug gap is correct on your plugs. The gap spec given on the radiator support said .062-.068. With these fine wire platinums it’s not a good idea to jam feeler gauges in there. So do your best to get it close, most of the time with the Motorcraft stuff it’s dead on. All mine where surprisingly. I used an old autolite to give an example.

Install the new plug. Try not to bang the tip on anything while putting it in the socket, this CAN throw the gap off. When tightening the plug, don’t crank on it. It only needs to be tightened to 13 ft/lbs, in other words….. snug with a socket and 3/8 ratchet.

Then take off the wire completely, and match it to one in the kit.

Plug wires I used:

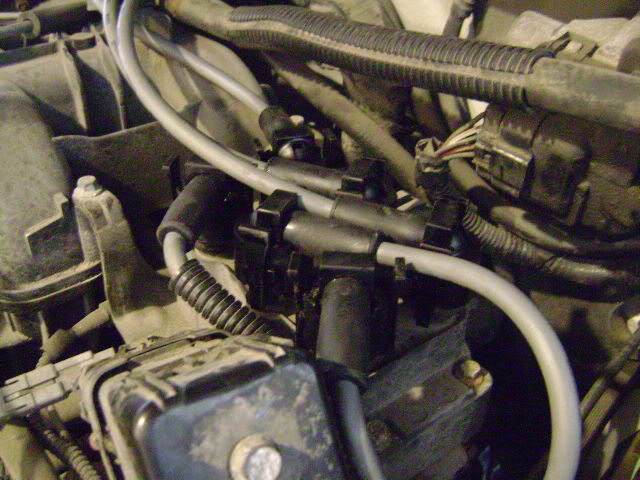

Install the NEW wire, following the route the old one used, and laying it into the plastic guides/retainers……..

Repeat with cylinders #5 and #6. Then move to the passenger side for cylinders #1-#3.

Big tip for the driver’s side.

Break your front passenger wheel loose.

Jack up the front of the truck.

Add jackstands to the nifty little hooks on the front of the lower control arms, and let the truck rest on the stands.

Remove your wheel. Now check out the removable fender apron…..

Remove the Christmas tree fasteners and the apron.

Ta da!

Repeat what happened on the other side, but try and keep your sanity. It took me a little while longer on this side. It’s a constant battle of using different combinations of 3/8 ratchet (standard and flex head), extentions and swivels. AND going from top, to fenderwell and back in order to complete the job. You’ll get it, but it’ll just try your patients.

Make sure all your wires are ran:

Fire her up and check for proper operation……..

If there is a miss check for disconnected wires, or plug wires not seated all the way. After that double check proper coil order to cylinder order.

If there are any questions please ask. It will only benefit to the article.

Thanks,

Ryan

Another thing to add….its not a bad idea to blow out around all the plugs with compressed air before removal to get any dirt/debris out of there before you pull the plug and let it drop into the cylinder.