This is an automatic engagement solution for an early type A4LD 2 wire lock-up. The pressure switch is installed in the governor portion of the transmission body. When the fluid pressure reaches the switch tolerance the switch closes completing the circuit and energizing the solenoid. This should occur at highway speeds (45+ MPH) when shifted into overdrive.

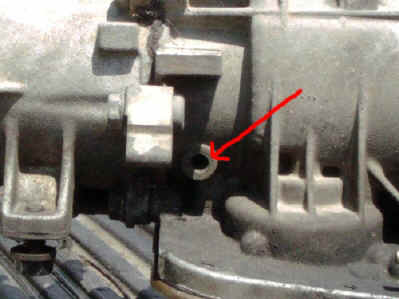

On the passenger side of the transmission toward the back at the bottom near the tail extension locate a protrusion with a hole in the center which resembles a bolt boss. This is the governor area of the transmission. Using a 3/16″ drill bit coated with grease to collect shavings carefully drill in the center of this hole until it punches through into the internal chamber.

Start the engine and let it run for about a few seconds which will force out any remaining shavings (transmission fluid will stream out forcing the remaining debris out).

Using an 1/8″ pipe thread tap, tap threads into the boss about 1/2″ deep. It may be necessary to open up the hole a little prior to tapping. Use the size drill bit recommended on the tap. Run the engine again to force out remaining debris.

Thread in a 44 to 52 PSI pressure switch into the hole.

Run a hot wire to one side of the transmission plug and the other wire to the controlled ground pressure switch. Drive the vehicle and once you reach highway speed (45+MPH) shift into overdrive and pay close attention to the feel of the shift. If it feels firm and you don’t experience erratic “in and out” OD shifting then you were successful. If it does shift “in and out” erratically you may need to experiment with different tolerance pressure switches until you find what works best for you.

Link:

Transmissioncenter.net sells the pressure switch HERE.

About The Author

Jim Oaks is the founder of TheRangerStation.com, the longest-running Ford Ranger resource online since 1999. With over 25 years of hands-on experience building and modifying Ford Rangers — including magazine-featured builds like Project Transformer — Jim has become one of the most trusted authorities in the Ford Ranger off-road and enthusiast space.

Since launching TheRangerStation.com, Jim has documented thousands of real-world Ranger builds, technical repairs, drivetrain swaps, suspension modifications, and off-road adventures contributed by owners worldwide. TheRangerStation.com has been referenced in print, video and online by enthusiasts, mechanics, and off-road builders looking for practical, and experience-based information.