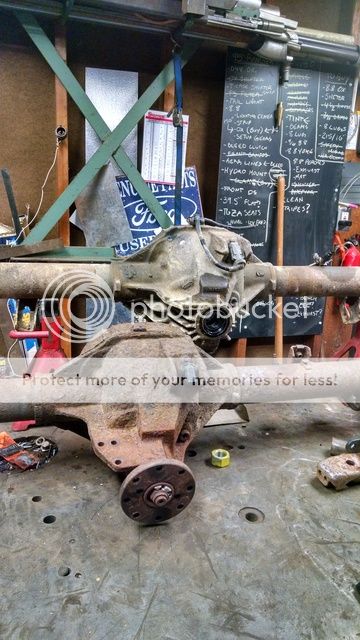

Made some progress on the hydro assist setup.

The cylinder I already had was a pretty cheap design with welded bushings on both ends made to pinned on, not clamped down with a bolt like a rod end. With the highsteer setup I no longer had the tierod to protect it on the axle,and the track bar prevents me from mounting it to the axle tube. I decided that first I needed to convert the cylinder to use traditional rod ends so I could simply bolt the ends down using a common bolt on the drag link or tierod.

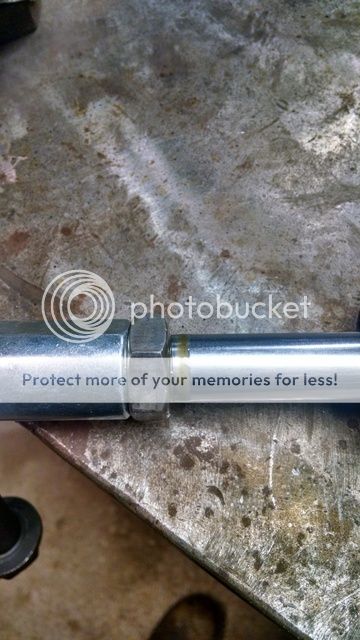

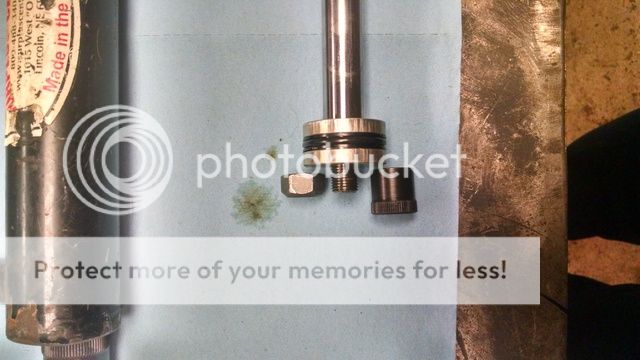

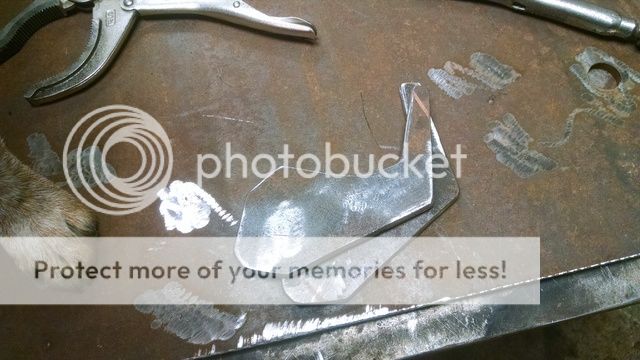

I dissaembled the cylinder and cut the bushing ends off, then I took a 3/4-18 die and treaded the rod so I could use a female 3/4" rodend. I clamped the rod in the vise with some plywood soft jaws and had to tether a wrench on the gland nut to keep the rod from turning as i ran the die down it.

I had to thread down about 1.25" to get decent thread engagement and have room for a jam nut...I didnt have that much rod to spare, so I traded the gland nut out for an "internal hex nut" that was a bit taller and will bottom out internally before the jam nut bottoms on the seal.

Since I was already ordering stuff from McMaaster i boughta 3/4-18 "internal hex nut" to use as a weld bung on the other end of the cylinder.

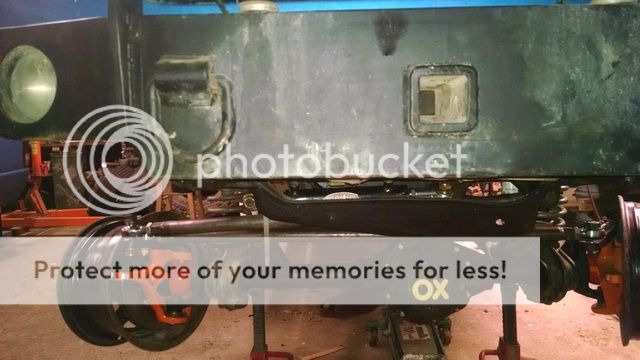

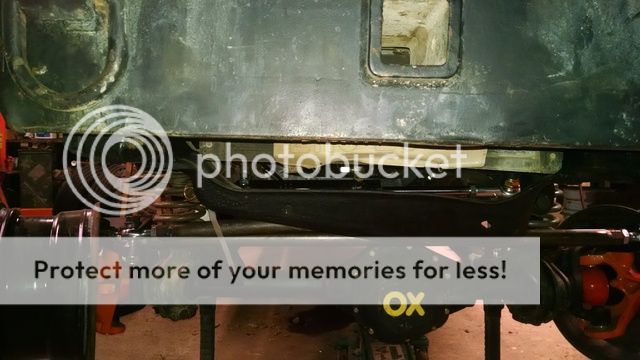

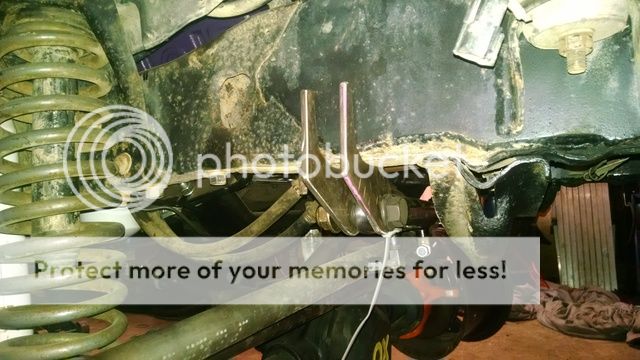

With everything converted to rod ends my mounting possibilties really opened up. After some looking around and talking with a few people in similar situations..I decided to mount off the pitman arm and the passenger frame rail. It has just enough stroke and its 100% out of harms way.

I cut out the tabs and punched the holes....but I still need missalignment spacers before I can weld everything up.

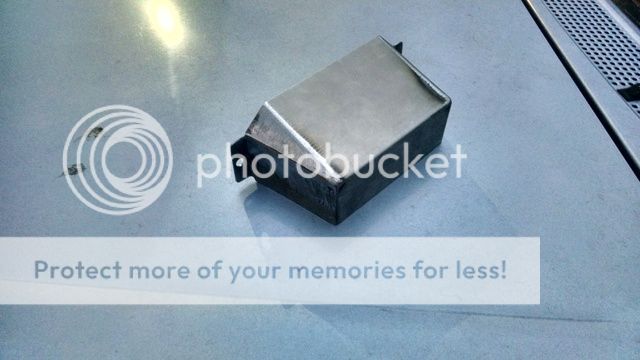

I swapped out the standard misalignments on the drag link to "safety" misalignments with the larger flange. It should take a little stress of the bolt since it is in single shear. My 8.8 shock tabs showed up with them.

I also finally retired my trusty $50 grinder...I needed to replace the cord and found the brushes are starting to groove up the armature..so I replaced it with the 13A 4.5"/5" model. This thing is a tank! I will still throw new brushed in the eco grinder and run it till it pukes though.lol

Got tired of working in the dark and put up a few 48x24" T8 fixtures over my bench.