here's what I got so far done to it.

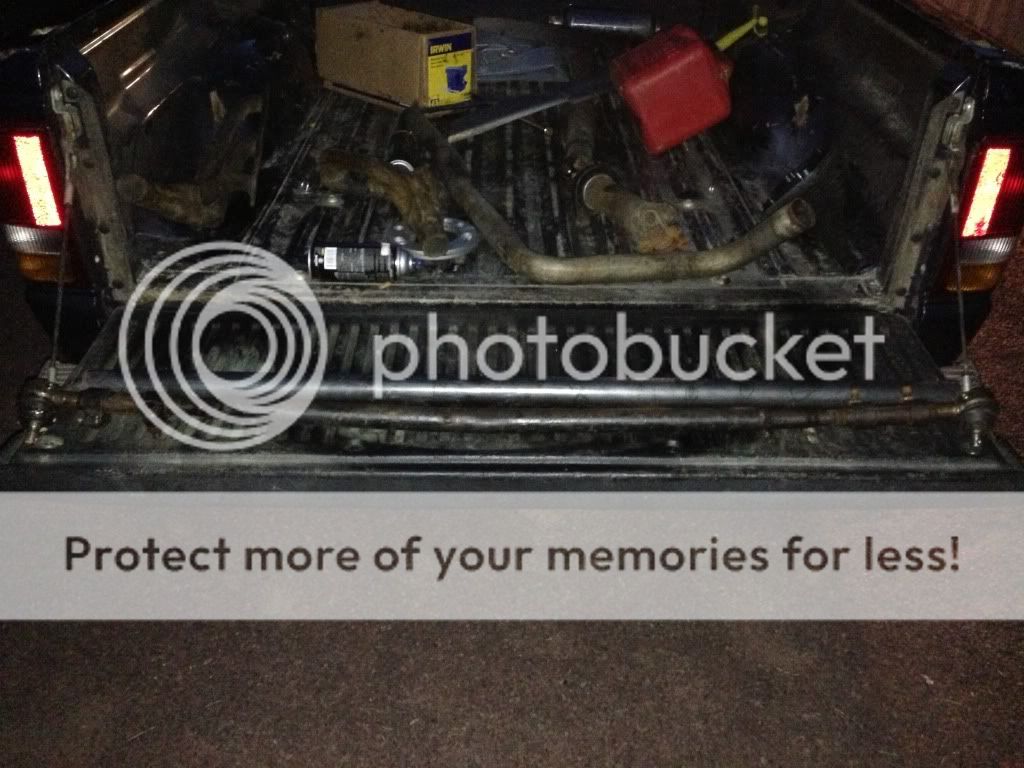

dana 44's front and rear

5.35 lockers

leather mountaineer seats

infinity speakers with 2 12in JL woofers with JL amp.

stock 4.0 5 speed new clutch

custom driveshafts

diff covers

new master cylinder, brake booster, and all lines

installed a alarm system

national leaf springs in the rear

here's the pics lots more to come

welded the radius arm brackets together to eliminate twisting and minimize movement

lots more to come within the month. rebuilding the whole front end next week when I get a Saturday to myself and prepping and painting the underneath with por15.

dana 44's front and rear

5.35 lockers

leather mountaineer seats

infinity speakers with 2 12in JL woofers with JL amp.

stock 4.0 5 speed new clutch

custom driveshafts

diff covers

new master cylinder, brake booster, and all lines

installed a alarm system

national leaf springs in the rear

here's the pics lots more to come

welded the radius arm brackets together to eliminate twisting and minimize movement

lots more to come within the month. rebuilding the whole front end next week when I get a Saturday to myself and prepping and painting the underneath with por15.

Last edited: