- Joined

- Apr 13, 2009

- Messages

- 15,097

- Vehicle Year

- '06, '11

- Engine

- 3.0 V6

- Transmission

- Automatic

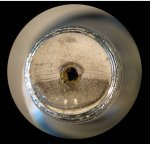

I swapped winter tires onto my work truck, a 2006 Dodge Ram 1500. I torqued the nuts to 110psi to start, and was going to finish at 135 as stated in the book. Sheared off a lug at 110! Not sure how that happens? Perhaps someone previously over tightened it. Now i have to fix the damn thing...and the snow finally started sticking a couple days ago and i have no shelter to work in. Woah is me...lol.