in the parts list I had listed that I got this steel fuel line as well.

I also finally got a response from the fuel sending unit seller, they stated that the in tank pump is 4-6 psi. I am not sure it will lose too much pressure from there to the front so I won’t know until it’s together if I will need to install a in line fuel sending unit. I may install a brake from steel to rubber there just to leave room for the addition later on.

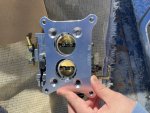

Yesterday I took off the thermostat housing to swap thermostats and it was caked with some goopy antifreeze. So instead of just changing the thermostat I will also need to change the housing as well just to be safe. Good thing I checked the thing was about half the size for flow then normal and the thermostat was toast.

Just going to add it to the parts pile.