Getting my 1996 Ford Ranger ready to pass a state emission inspection, I had to diagnose Ford trouble codes P0401 and P1443.

P1443 EVAP Emission CTRL System CTRL Valve

What could cause the P1443 code:

- Defective charcoal canister. If the purge valve is located close to the canister, disintegrating charcoal can (and often does) enter vacuum lines, and eventually interfere with the operation of the purge valve.

- Defective purge valve and/or control solenoid

- Damaged, burnt, shorted, corroded, and disconnected wiring and/or connectors.

- Damaged, split, hardened, dislodged, or degraded vacuum lines. In these cases, other codes may be present as well.

- Defective PCM. Note though that this is a rare event, and the fault must be sought elsewhere before any controller is replaced.

- Loose fuel filler cap

- Faulty EVAP Canister Purge Solenoid Valve

- EVAP Canister Purge Solenoid Valve harness is open or shorted

- EVAP Canister Purge Solenoid Valve circuit poor electrical connection

- Blocked hose between the purge valve and FTP sensor Faulty

- EVAP Fuel Tank Pressure (FTP) Sensor

P0401 Exhaust Gas Recirculation Flow – Insufficient Detected

What could cause the P0401 code:

- Clogged or restricted EGR passages

- Faulty EGR valve

- EGR valve stuck closed

- Problems with the DPFE sensor (Ford)

- Problems with hoses to the DPFE sensor (Ford)

- Problem with the EGR vacuum switching valve (Toyota)

- Clogged catalytic converter

- Carboned up EGR temperature sensor

- Vacuum supply issues at the vacuum-operated EGR valve

- Electrical problems with the EGR valve control circuit

- Engine computer problems

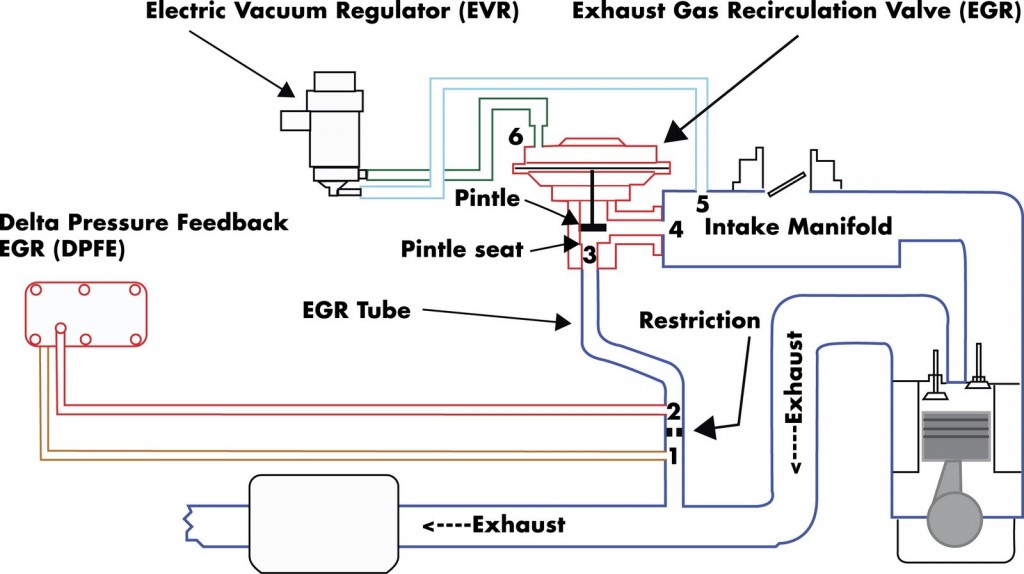

Here’s How Ford EGR Works

When certain driving conditions are met and the computer wants exhaust gas recirculation, it provides a pulsing voltage to the electronic vacuum regulator (EVR). The EVR is a solenoid valve. When it opens, it allows intake manifold vacuum from port 5 to flow into port 6 on the top side of the EGR valve. The vacuum pulls up on the diaphragm, lifting the pintle off the pintle seat. With the pintle off its seat, exhaust pressure forces exhaust gas up through the EGR tube, the EGR valve, and into the intake manifold at port 4. On the way up to the EGR valve, the exhaust gas passes through a restriction. The DPFE sensor hoses are connected to ports 1 and 2—before and after the restriction. By comparing and reporting the differences in pressure, the computer can determine exactly how much exhaust gas is flowing through the EGR valve.

What Goes Wrong With The Ford EGR System

Exhaust gas contains water vapor. Ford did consider the ramifications of this water vapor getting into the DPFE and forming ice. So they programmed the computer to ignore an EGR malfunction if the temperature is below 32°F. Unfortunately, Ford didn’t give enough consideration to the impact of corrosion inside the DPFE, and that’s what causes most of the EGR related problems.

Do it yourselfers and professional technicans make an all-too-common mistake if they automatically replace the EGR valve when they see an EGR related code. In fact, the valve itself is usually the most reliable component in the system.

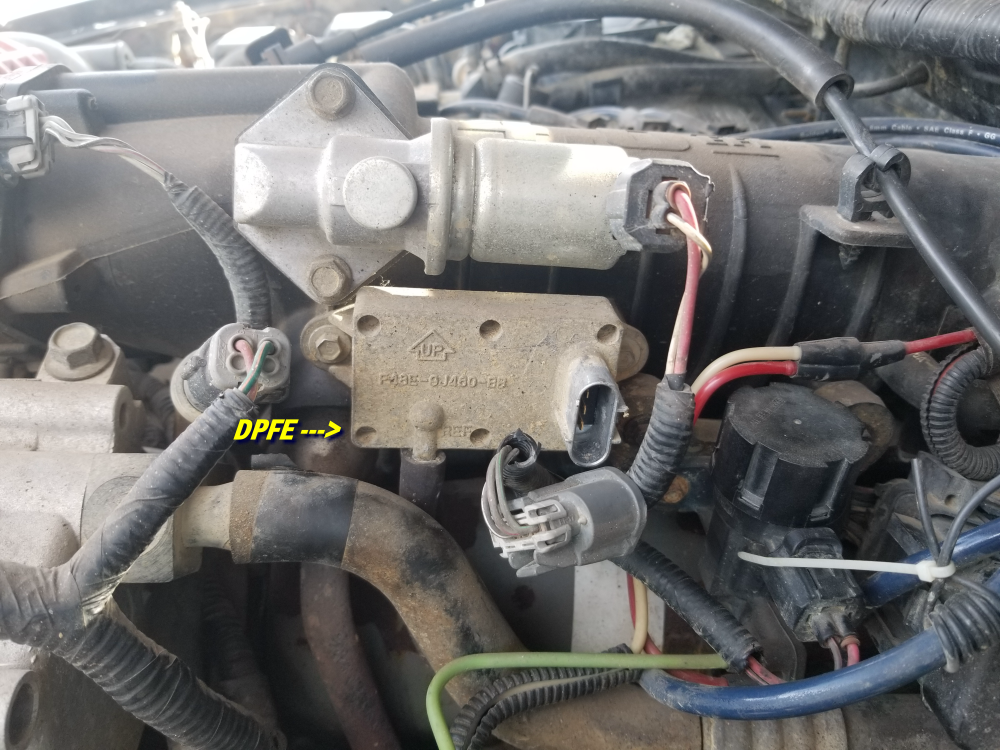

DPFE Test & Replacement

Step 1 – Check the condition of the vacuum hoses going to the DPFE sensor and the EVR. Look for cracks or tears. Replace the hose if you find any.

Step 2 – Check the operation of the DPFE with the engine off, key in the run position. Using a digital voltmeter, check for voltage on the brown/light green wire. Look for a reading between .45 and 1.1 volts. If your reading is outside that range, you have one more voltage check to perform before replacing the sensor. Check the voltage on the brown/white wire. It should read 5 volts. If it doesn’t, the sensor isn’t getting power from the computer. Then it’s a whole new ballgame. If you have 5 volts, and the reading from the brown/light green wire is outside the range, replace the DPFE. After replacement, perform the voltage check again to eliminate the possibility that the EGR valve is not seating properly.

Step 3 – Leave your meter connected and start the engine. The voltage SHOULD NOT CHANGE! That’s because there should be no EGR flow at idle. If the DPFE voltage changes, either the EGR pintle isn’t seating properly and it’s allowing exhaust flow past the seat, or the DPFE is bad.

Step 4 – Remove the EGR valve and check the condition of the pintle, pintle seat, and the EGR passages. They will be coated with black soot. But the passages should not be clogged and the pintle should move off its seat with the application of vacuum. Clean

the pintle, pintle seat, and passages with carb or throttle body cleaner.

I ordered a new DPFE and replaced it.

Cleared The Codes – P1443 Came Back

After replacing the DPFE and clearing the codes, the P1443 EVAP Emission CTRL System CTRL Valve code came back.

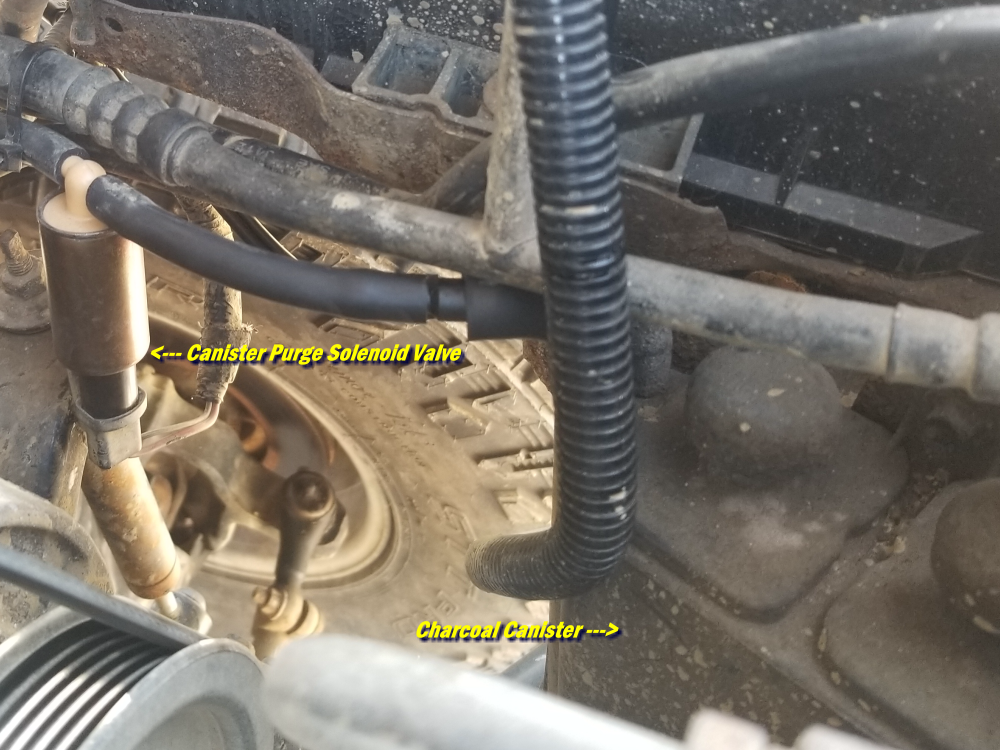

My next step was to replace the Canister Purge Solenoid Valve that’s located down by the charcoal canister.

What Does The Canister Purge Solenoid Valve Do:

The purge valve is the part of the vehicle Evaporative Emission Control (EVAP) system.

The EVAP system prevents fuel vapors in the fuel tank from escaping into the atmosphere. The EVAP system traps fuel vapors from the fuel tank and temporarily stores them in the charcoal canister, see the diagram.

When the engine is running under certain conditions, the fuel vapors are purged from the canister and burned inside the engine. The purge valve precisely controls the amount of fuel vapor that is purged from the charcoal canister.

In modern cars, the purge valve is an electrically-operated solenoid, that is controlled by the engine computer. When the engine is off, the purge valve is closed. When the engine is running and fully warmed up, the engine computer gradually opens the purge valve to allow some amount of fuel vapors to be moved from the charcoal canister and burned in the engine. The purge flow is monitored by a number of sensors. If the purge flow is less or more than is expected under the conditions, the computer illuminates the “Check Engine” light.

Don’t Make This Mistake!

While changing out the Canister Purge Solenoid Valve I realized that the hose between the valve and the charcoal canister was rotted out and cracked.

I should have inspected the rubber hoses first. The parts store didn’t have a replacement hose, so I made one with a rubber vacuum hose, plastic vacuum line connector, and a 90 degree elbow.

In all honesty, the P1443 code was probably caused by the leaking hose. I strongly suggest that you check the hose between the charcoal canister and the valve before replacing the valve.

It’s Fixed!

After replacing the hose, valve, and clearing the code, the system was fixed and the code never returned.