Resource: Hot Rod Magazine – Ford High Performance Volume 1 Number 4 (Display through January 8, 1985)

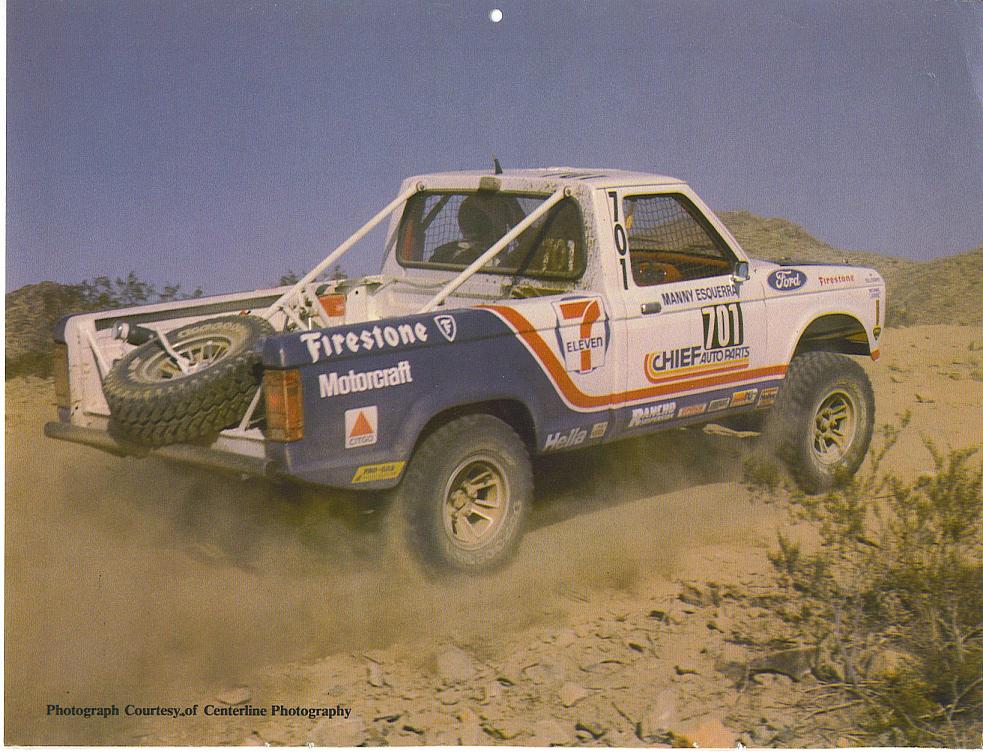

Ford V8 and high performance have been synonymous for years, but you don’t need eight cylinders to go fast. Bill Stroppe has been demonstrating that to the off-road fraternity with a V6 Ford truck that’s following in the dusty but successful tracks of other Stroppe-created dirt-busters, such as the Big Oly Bronco that Parnelli Jones beat the deserts with not so many years ago.

Byron Froelich is the man who builds the powerplants for Stroppe’s truck. He knows Fords inside and out, and he’s managed to double the horsepower of the 2.8-liter V6 without resorting to exotic tricks or expensive fabrication. This engine is currently used only in Ford’s Ranger and Bronco light trucks, but it’s been around since the early Seventies, when it started out with 2.3 liters. It has since been enlarged to 2.8 liters and, over the years, has been used in some Mustangs and Pintos, as well as pickup trucks.

“This is an unusual engine,” Froelich says. “It’s a loner, it’s by itself. There’s virtually nothing that interchanges with other engines.” And, there’s not much in the way of performance parts, either. The 2.8-liter V6 is a Catch-22 engine – it’s not popular enough to justify investment by aftermarket manufacturers, and few people use it because high performance equipment isn’t available.

Froelich’s version is fairly conservative because of the scarcity of go-fast equipment and the off-road class rules. “We’re limited to 2850 cc in displacement, so there’s no use trying to put a stroker in it, or bore it out or do other major modifications,” he says, “We go through the engine and give it the complete shot as far as blueprinting, clearances and deburring the block and that sort of thing.” But otherwise, the modifications are minimal, although they’re effective.

The block and bottom end, except for the usual detailing, are untouched. Froelich uses an SVO high-performance oil pump and the best available bearings, TRW T-77s, but that’s about it.

The stock rods are replaced with Ford’s 289 hig-performance models. They’re very close to the length of the V6 rods, but they’re much stronger. “The 289 rod is basically one heck of a good rod. It’s vacuum forged; it’s good stuff,” Froelich says. However, because the 289 rods are thicker than the stock units, the V6’s crank journals have to be widened by about 0.015 inch. Also, the bearings must be chamfered on the edges to keep the rods from riding up the fillet of the crank. “I bolt a bearing into the rod, take it to Velasco (a Southern California crankshaft grinder) and have him give me 0.010 side clearance and 0.002 bearing clearance,” Froelich says.

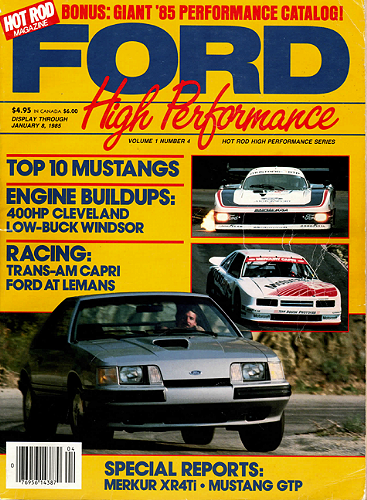

The crankshaft is stock, but Froelich fits a vibration damper to the nose of the crank and takes care that everything is precisely balanced. “Since it’s a V6, it has a lot of harmonics,” he explains. This condition caused difficulties with aftermarket timing gears. The entire center sections of the large cam gear would rip away from the tooth ring. Froelich went back to using the stock gear, which has Teflon teeth, and has experienced no difficulties with it. “This might have helped to take the harmonics out,” he figures, since Teflon has more flexibility than the steel aftermarket ring and can absorb more of the vibrations that pass from the crank to the camshaft.

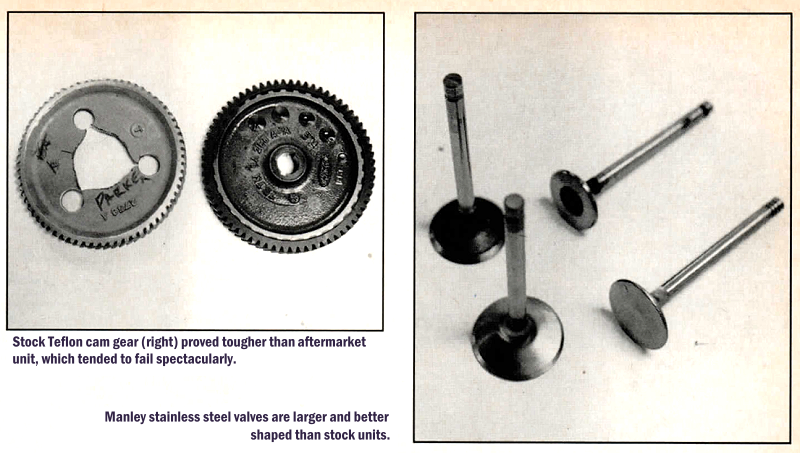

Pop-up of Venolia Piston (left) was smoothed along the radius to prevent carbon buildup.

Froelich uses Venolia pop-up-type pistons with 11.7:1 compression and 0.0065-inch wall clearance. He modified the dome of the pistons somewhat to prevent carbon from collecting in the relatively sharp radius between the piston top and the dome. “I pent-roofed it, making a tent out of it, you might say, and I don’t get that build-up anymore.” Froelich says, adding, “The burn looks better.”

The V6’s bottom-end has been reliable and has never presented any difficulties, but Froelich says, “I have experienced some problems with cam bearings, I believe that with the harmonics passing through the engine, the cam is twisting like a snake. Of course, when this happens, it shuts off some oil someplace, so I give it a little bit more clearance on the cam bearings.” He has the cam journals ground 0.010 under.

Froelich also uses a stock cast-iron cam that’s reground by Eagle. “With this engine, if you’re going to run a flat tappet, cast iron is the way to go.” Cast iron does not flex, but steel can twist like a torsion bar and affect timing and lubrication. The cam grind is relatively mild since it must be a compromise. “In our particular case, we’re looking for more low-end torque, because we come to abrupt stops and have to accelerate, but we’re kind of greedy and want performance at both ends.” The Engle cam has satisfied these requirements.

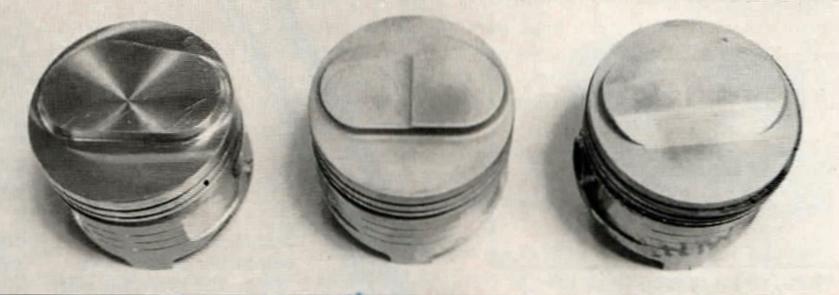

Some lifter problems surfaced during the initial development of the engine. Froelich originally used a shell lifter (which is hollow and has the pushrod seat at the bottom, much like a thimble). But, since there are no provisions for oiling the lifters, the pushrods seized and sheared off. Froelich cured this malady by using stock Ford V8 hydraulic lifters, which have the same diameter as the V6 units. Froelich modifies these lifters by removing their “guts” and dropping the socket to the bottom. The lifters have holes in their sidewall and, as oil drips into down into them from above, they fill up. Since there is taper in the cam lobe, the lifters spin and throw oil onto the lifter bore, keeping everything well lubricated. The rest of the valvetrain includes stock pushrods, Manley stainless steel valves and Engle springs and retainers.

Froelich completes his modifications to the valvetrain by flash chroming the rocker shafts. This makes the shaft harder and keeps the rocker arms from seizing. The rocker shaft is undercut, flash-chromed and then ground to give a rocker clearance of 0.003, a thousandth more than stock. The oil holes are chamfered, and a restrictor is placed in the oil passage from the rocker shaft to the head. Froelich limits the oil flow for racing use but, “for street use, I probably wouldn’t recommend it.” The stock adjustable rocker arms have given trouble free services.

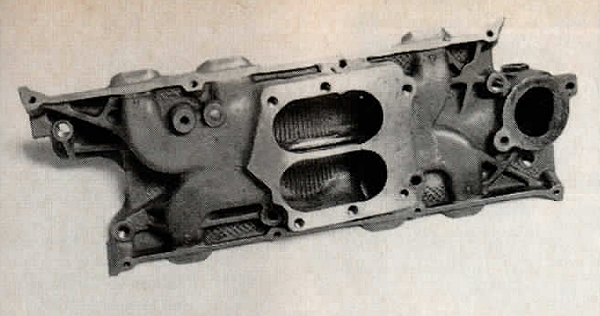

Stock two-barrel manifold has been modified to accept Holley 465 four-barrel

The induction system is basic and unsophisticated. The stock manifold was modified to accept a four-barrel Holley 465cfm carburetor. “It’s not good,” Froelich admits, “but it’s better than anything else available.” The rules allow one venturi per cylinder. “Theoretically, we could put six single-throat carburetors on it if we wanted to,” Froelich says. But he prefers the four-barrel for the sake of simplicity. “It seems to work quite well, it’s very responsive. I originally had a 390, which is quite nice for the street, but it wasn’t quite enough for performance.” The ignition is Ford electronic with SVO-MSD modules and has performed without a hitch.

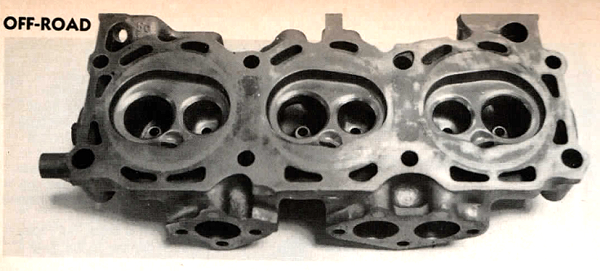

Cylinder head is mildly modified by matching and polishing ports.

It’s tough to make the engine breath because of uneven port spacing and length.

The cylinder heads are mildly ported, matched, and the ports are smoothed, though not polished to a high luster. There’s not much you can do with these heads since they have unequally spaced ports of unequal length. “It makes manifold distribution none too hot,” Froelich says. “Number one and number six run hot.” He’s tried to compensate for the condition by experimenting with carburetor jetting, but it has had no effect.

Despite the heavy impositions of off-road racing, only one V6 has failed. One of its wrist pins broke and demolished the block. “And I blame it on myself for not replacing them,” Froelich admits. He says. “They’re very responsive little engines. They don’t mind RPM and being off-road, they go through many ranges of RPM, from a dead stop to over 7000.” Stock, the V6 is rated at 105 horsepower. Froelich says, “We’re getting over 200.” That’s an impressive achievement, particularly when you consider that there’s not much high-performance equipment available and the engine offers some inherent difficulties that are difficult to overcome. Also, on the challenging and highly competitive off-road racing circuit, Stroppe has blown off trucks powered by sophisticated, twin-cam motors. Not bad for a close-to-stock V6.

Here’s Byron Froelich (left) and Bill Stroppe (right) with a 2.9L V6

PDF Article:

To see a scanned PDF version of this article, click on the image below.

Related Article

About The Author

Jim Oaks is the founder of TheRangerStation.com, the longest-running Ford Ranger resource online since 1999. With over 25 years of hands-on experience building and modifying Ford Rangers — including magazine-featured builds like Project Transformer — Jim has become one of the most trusted authorities in the Ford Ranger off-road and enthusiast space.

Since launching TheRangerStation.com, Jim has documented thousands of real-world Ranger builds, technical repairs, drivetrain swaps, suspension modifications, and off-road adventures contributed by owners worldwide. TheRangerStation.com has been referenced in print, video and online by enthusiasts, mechanics, and off-road builders looking for practical, and experience-based information.