cstishenko

Well-Known Member

Mods: Can you please sticky this, or add it to the 98+ lift FAQ's thread?

Did you notice that after doing your torsion bar lift in the front of your Ranger than the ride became uncomfortable or brutally rough? It could be that your shocks are simply not long enough for the lift you've added to your truck.

Your stock shocks were designed to operate within the trucks stock ride height. As you turn up your torsion bars you run the risk of over extending your shocks by pulling them fully extended against their stops! This WILL result in a poor ride, and poor offroad capability. This could also result in a failure while driving causing an accident.

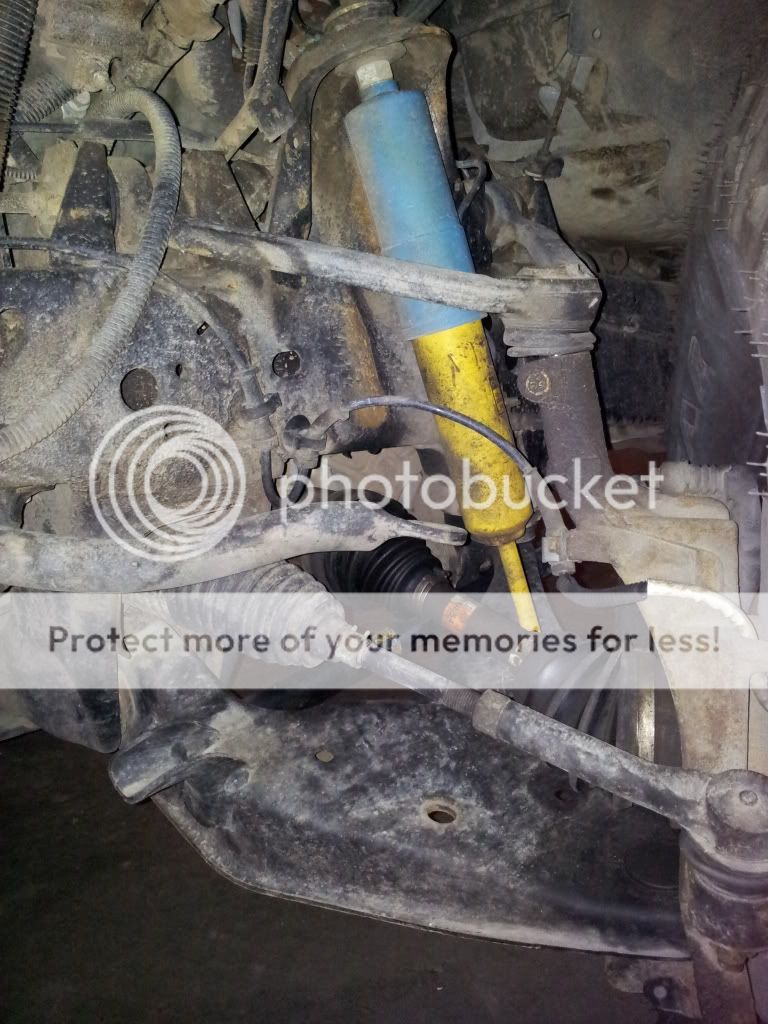

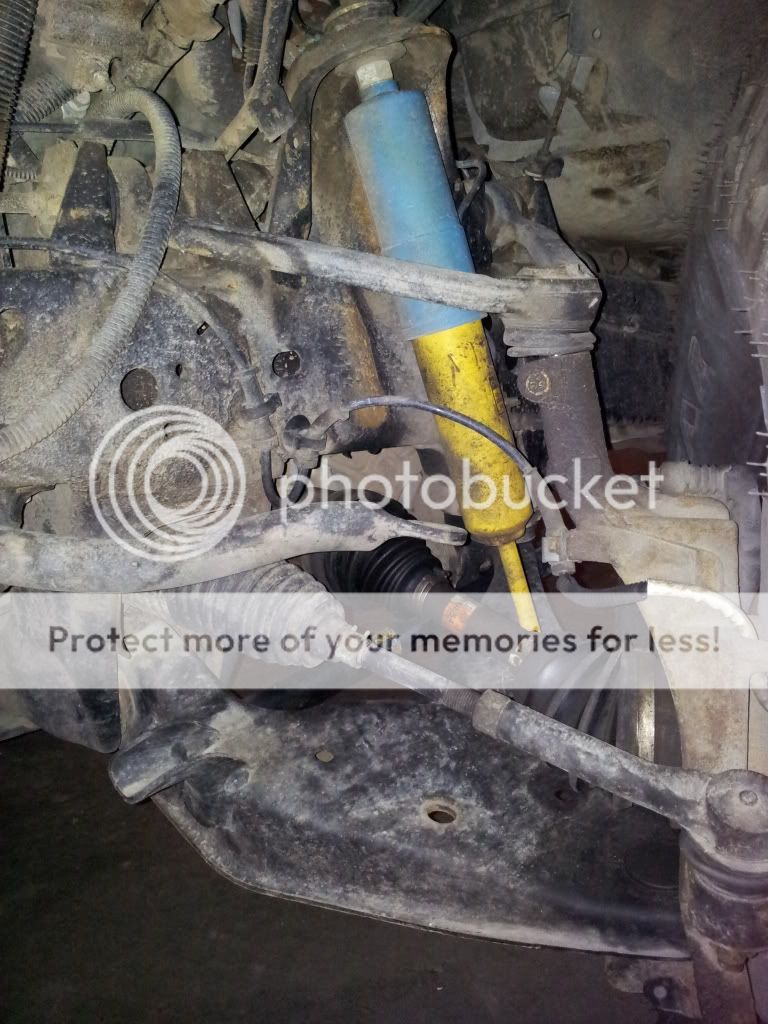

Here are my homemade shock spacers. With the truck on the ground at a full torsion twist, you should gain another half an inch to an inch depending on your bars once you un-do your lower shock mounts! Try this and see what happens... Worst case, you wasted some valuable beer drinking time. Best case.. You truck rides smoother and is more capable off-road.

For the Bottom Mount:

Take off the nuts holding your lower shock mount to the trucks a-arm. I took 8-10mm nuts and wound them on tight to the lower shock studs. Two nuts per stud. I re installed them in the lower mount and tightened the lower nuts under the a-arm again.

For the top Mount:

Take the upper nut off. then take both washers and both rubber bushings off. You should be able to push the shock down now. I then put on a thick 5/8 nut that would butt up against the "flat" portion of the shock shaft that the washer sits on. Re-install the lower washer and bushing. Put the shock back into it's upper mount.. Re-install the upper bushing, washer and nut. DONE.

My ride IS the same as stock and i'm up 2-2.5" over stock just by turning up my tbars in my FX4 L2

Did you notice that after doing your torsion bar lift in the front of your Ranger than the ride became uncomfortable or brutally rough? It could be that your shocks are simply not long enough for the lift you've added to your truck.

Your stock shocks were designed to operate within the trucks stock ride height. As you turn up your torsion bars you run the risk of over extending your shocks by pulling them fully extended against their stops! This WILL result in a poor ride, and poor offroad capability. This could also result in a failure while driving causing an accident.

Here are my homemade shock spacers. With the truck on the ground at a full torsion twist, you should gain another half an inch to an inch depending on your bars once you un-do your lower shock mounts! Try this and see what happens... Worst case, you wasted some valuable beer drinking time. Best case.. You truck rides smoother and is more capable off-road.

For the Bottom Mount:

Take off the nuts holding your lower shock mount to the trucks a-arm. I took 8-10mm nuts and wound them on tight to the lower shock studs. Two nuts per stud. I re installed them in the lower mount and tightened the lower nuts under the a-arm again.

For the top Mount:

Take the upper nut off. then take both washers and both rubber bushings off. You should be able to push the shock down now. I then put on a thick 5/8 nut that would butt up against the "flat" portion of the shock shaft that the washer sits on. Re-install the lower washer and bushing. Put the shock back into it's upper mount.. Re-install the upper bushing, washer and nut. DONE.

My ride IS the same as stock and i'm up 2-2.5" over stock just by turning up my tbars in my FX4 L2

Last edited: