- Joined

- Oct 10, 2010

- Messages

- 255

- Points

- 1,601

- City

- shreveport louisiana

- Vehicle Year

- 91

- Transmission

- Automatic

ready to see this thing in the sunlight!

![]() Welcome Visitor! Please take a few seconds and Register

for our forum. Even if you don't want to post, you can still 'Like' and react to posts.

Welcome Visitor! Please take a few seconds and Register

for our forum. Even if you don't want to post, you can still 'Like' and react to posts. ![]()

So I have done my disk brake conversion on my 9" I just need to burn it in and paint it up and she will be done. I will get some pics once it is all burned in.

Also I am contemplating what D44 to use up front. I currently have a HP '79 F250 that was a radius arm setup with disks. I have a friend that has a leaf sprung HP D44 with brakes that he said I could have. I am trying decide which housing would be better. My ultimate goal is to 4link or, 3link with a PHB. I am just not sure if there is that big of a difference between the axle housing of the 2. I do know that the way the radius arm brackets are welded onto the housing are different and mine aren't able to be cut down. So I am just lost a little on that.

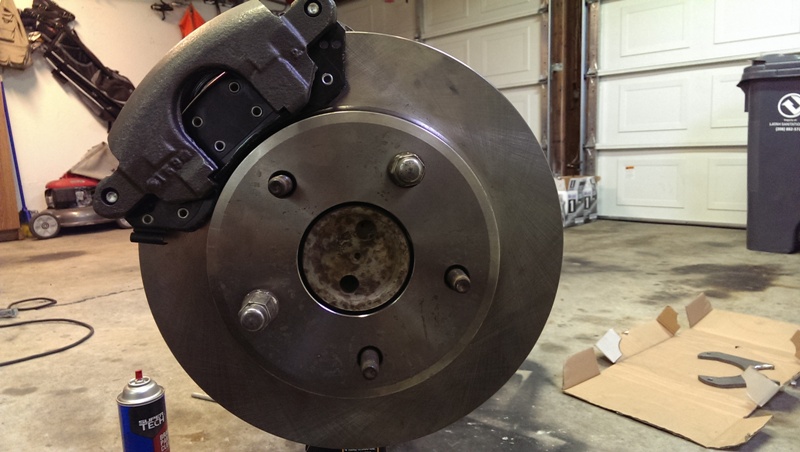

So here is how far I have gotten on my disk brake swap. This is the hardware that I am using for my swap. Weld on brackets from Ruffstuff, Cheby 3/4ton front calipers and pads. And the kicker 2007 Mitsubishi Raider rotors. They are the only rotors that I found with a 5 on 5.5 pattern that the axle flange actually clears.

Just a shot from looking down the housing.

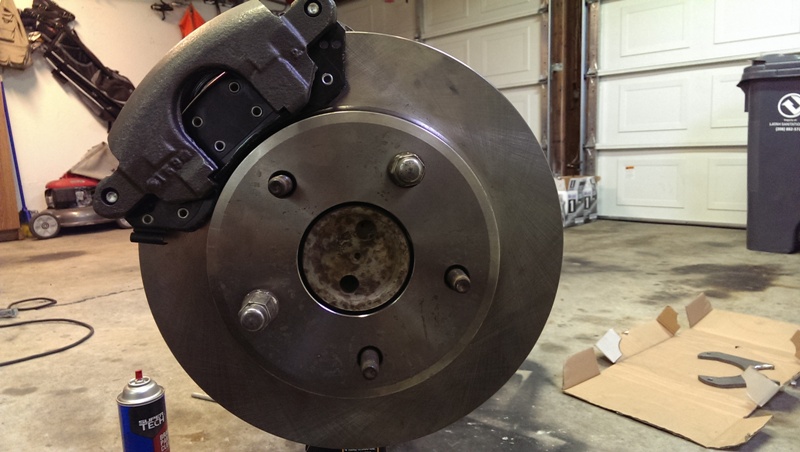

Side view with the rotors and caliper.

The rotor sitting over the caliper.

That is how much clearance I have between the axle flange and the inside of the rotor.

Now here are the problems:

It's hard to see but the caliper is rubbing on the wheel.

Different angle, but where the mark is, is about where it is hitting.

This isn't a big problem just more of a concern. The lug studs are smaller than the holes in the rotors so there is slop. I was thinking about drilling out the shaft and pressing in bigger studs to make it fit better. My current issue is that with a lug nut bolted directly to the rotor I can center the rotor and everything is alright. However as soon as I put the wheel on the rotor sags and it becomes off center.

What I was thinking was if I could get a wheel spacer and put it in it would help with the clearance a little bit. I don't think they make them but wheel spacers that are dimpled so they fit into the rotor to help center it. I have already ground the caliper down a bit on top to help with the clearance issue but the backspacing of the wheel seems to be causing problems a bit.