-

Welcome Visitor! Please take a few seconds and Register

for our forum. Even if you don't want to post, you can still 'Like' and react to posts.

Welcome Visitor! Please take a few seconds and Register

for our forum. Even if you don't want to post, you can still 'Like' and react to posts.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

86 ranger front upper ball joints?

- Thread starter RangerGoolz

- Start date

- Joined

- Sep 21, 2007

- Messages

- 1,731

- City

- Wa, Bremerton 98310

- Vehicle Year

- 1987

- Total Lift

- Ranger 5" (1½" Hiryder/3" body), BII 4" Procomp

- Total Drop

- Ranger 5sp, BII A4LD

- Tire Size

- Ranger 32"/4:10LS, BII 33"/3:73LS

- My credo

- Deengineer until it is how Blue Oval should have sold it!!

If you have the coil spring unsprung and unmounted, then I would loosen the top ball joint first, then the lower. With the control arm removed, I would complete the removal and replacement process.

RangerGoolz

Active Member

Thanks Gaz, I just dont know how to get the ball joint out.

Curious Hound

Formerly EricBphoto

TRS Event Staff

TRS Forum Moderator

Supporting Member

U.S. Military - Veteran

TRS 20th Anniversary

VAGABOND

TRS Event Participant

GMRS Radio License

TRS 25th Anniversary

- Joined

- Feb 7, 2016

- Messages

- 18,146

- Age

- 61

- City

- Wellford, SC

- State - Country

- SC - USA

- Other

- 2002 F250, 2022 KLR 650

- Vehicle Year

- 1993

- Vehicle

- Ford Ranger

- Drive

- 4WD

- Engine

- 3.0 V6

- Transmission

- Manual

- Total Lift

- 6"

- Tire Size

- 35"

- My credo

- In theory, theory and practice are the same. In practice, they are different.

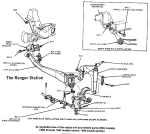

There us no control arm. This truck has twin I-beam suspension. The ball joints appear to be pressed into the axle beam. In the picture, it looks a bit different from the 4x4 version.

It appears that you need to get the knuckle off. So remove the nut from the lower ball joint and get the knuckle out if the way. Then, based on what I can see, you will press the ball joints downward out of the axle beam.

It appears that you need to get the knuckle off. So remove the nut from the lower ball joint and get the knuckle out if the way. Then, based on what I can see, you will press the ball joints downward out of the axle beam.

- Joined

- Sep 21, 2007

- Messages

- 1,731

- City

- Wa, Bremerton 98310

- Vehicle Year

- 1987

- Total Lift

- Ranger 5" (1½" Hiryder/3" body), BII 4" Procomp

- Total Drop

- Ranger 5sp, BII A4LD

- Tire Size

- Ranger 32"/4:10LS, BII 33"/3:73LS

- My credo

- Deengineer until it is how Blue Oval should have sold it!!

My bust, I try to use the correct terms, I thought knuckle, didn't have time to look it up, then thought "A" arm and I wrote control arm

I've use a "Pickle Fork" and 3-5lb hammer, I've also used ball joint. removal tool.

I've use a "Pickle Fork" and 3-5lb hammer, I've also used ball joint. removal tool.

Shran

Junk Collector

TRS Forum Moderator

Supporting Member

Article Contributor

Solid Axle Swap

Truck of Month

Yes... you need to remove the knuckle. I would thread one of the nuts back on partially and then whack the top of the knuckle with a sledge hammer... or use a pickle fork... the nut is there to prevent the knuckle from flying off when it breaks loose.

Then I would press out the top ball joint first, then the bottom one. Bottom one will go back in first, then the top. The screw on the ball joint tool will go through the upper ball joint hole when removing/installing the lower one.

Then I would press out the top ball joint first, then the bottom one. Bottom one will go back in first, then the top. The screw on the ball joint tool will go through the upper ball joint hole when removing/installing the lower one.

- Joined

- Mar 6, 2020

- Messages

- 1,815

- City

- 48022

- State - Country

- MI - USA

- Vehicle Year

- 1994

- Vehicle

- Ford Ranger

- Engine

- 4.0 V6

- Transmission

- Automatic

- Total Lift

- 1-1/2 inch front leveling

- Total Drop

- Stock

- Tire Size

- 31/10.50/15

- My credo

- What's the worst that could happen?

I didn't have much luck in removing my ball joints using the press, but it worked perfectly on the install. The Hammer was my best removal tool.

- Joined

- Sep 4, 2017

- Messages

- 897

- Age

- 47

- City

- Lyman

- State - Country

- ME - USA

- Other

- 1987 Ford bronco ii 2wd

- Vehicle Year

- 1987

- Vehicle

- Ford Ranger

- Drive

- 2WD

- Transmission

- Manual

- Total Drop

- 3'' front 4''back

- Tire Size

- 245 35 18

So does upper joint get pressed downward to get it removed? I m trying to get camber adjuster out but can't get it removed for the life of me.Old post I know

- Joined

- Mar 6, 2020

- Messages

- 1,815

- City

- 48022

- State - Country

- MI - USA

- Vehicle Year

- 1994

- Vehicle

- Ford Ranger

- Engine

- 4.0 V6

- Transmission

- Automatic

- Total Lift

- 1-1/2 inch front leveling

- Total Drop

- Stock

- Tire Size

- 31/10.50/15

- My credo

- What's the worst that could happen?

- Joined

- Sep 4, 2017

- Messages

- 897

- Age

- 47

- City

- Lyman

- State - Country

- ME - USA

- Other

- 1987 Ford bronco ii 2wd

- Vehicle Year

- 1987

- Vehicle

- Ford Ranger

- Drive

- 2WD

- Transmission

- Manual

- Total Drop

- 3'' front 4''back

- Tire Size

- 245 35 18

Not sure what I'm missing.doesnt show anything about removal or installation of ballpoint

Last edited:

- Joined

- Mar 6, 2020

- Messages

- 1,815

- City

- 48022

- State - Country

- MI - USA

- Vehicle Year

- 1994

- Vehicle

- Ford Ranger

- Engine

- 4.0 V6

- Transmission

- Automatic

- Total Lift

- 1-1/2 inch front leveling

- Total Drop

- Stock

- Tire Size

- 31/10.50/15

- My credo

- What's the worst that could happen?

Dang I thought someone would've responded by now.

I'm unfortunately not knowledgeable on the 87 4x2 set-up. I thought posting the image would help, but I guess not.

Where exactly are you with the removal process so far?

I'm assuming the steering knuckle is removed and the nuts, washers and retaining C-clips are removed. So you're just trying to figure out which way to pound on the ball joint?

Let us know and post a pic if you can...

I'm unfortunately not knowledgeable on the 87 4x2 set-up. I thought posting the image would help, but I guess not.

Where exactly are you with the removal process so far?

I'm assuming the steering knuckle is removed and the nuts, washers and retaining C-clips are removed. So you're just trying to figure out which way to pound on the ball joint?

Let us know and post a pic if you can...

- Joined

- Sep 4, 2017

- Messages

- 897

- Age

- 47

- City

- Lyman

- State - Country

- ME - USA

- Other

- 1987 Ford bronco ii 2wd

- Vehicle Year

- 1987

- Vehicle

- Ford Ranger

- Drive

- 2WD

- Transmission

- Manual

- Total Drop

- 3'' front 4''back

- Tire Size

- 245 35 18

I really don't need ball joints removed.i just need to knuckle remove from ball joints so I can remove camber adjuster.can t get adjuster to budge for the life of me.might have to pound on knuckle until ball joint shafts slide off knuckle.curious how much hammering will be needed to get it done.lol.i asked about ball joint removal to try the slide upper up enough so I can get adjuster to move.thats y I asked about ball joint removal

- Joined

- Mar 6, 2020

- Messages

- 1,815

- City

- 48022

- State - Country

- MI - USA

- Vehicle Year

- 1994

- Vehicle

- Ford Ranger

- Engine

- 4.0 V6

- Transmission

- Automatic

- Total Lift

- 1-1/2 inch front leveling

- Total Drop

- Stock

- Tire Size

- 31/10.50/15

- My credo

- What's the worst that could happen?

I'm not sure if that can be done easily, if at all. Depending on how long it -the camber adjustment bushing - has been in place, it may be welded to the knuckle. Ball joints are PIA, but trying to remove that bushing without removing the Ball joint would be worse.

On my 4x4 knuckle there is a cinch or clinch bolt that tightens around the bushing to stop it from moving. I don't see that part on the illustration I attached.

On my 4x4 knuckle there is a cinch or clinch bolt that tightens around the bushing to stop it from moving. I don't see that part on the illustration I attached.

- Joined

- Sep 4, 2017

- Messages

- 897

- Age

- 47

- City

- Lyman

- State - Country

- ME - USA

- Other

- 1987 Ford bronco ii 2wd

- Vehicle Year

- 1987

- Vehicle

- Ford Ranger

- Drive

- 2WD

- Transmission

- Manual

- Total Drop

- 3'' front 4''back

- Tire Size

- 245 35 18

The adjuster is in knuckle can t see why if I hit knuckle hard enough it would slide whole thing down from ball joints.i hope that is.like when your trying to get a outer tie rod end out.u remove nut from tie rod and smack it with a hammer and it pops off most of time.kinda same idea.no pinch bolts on 83-88 rangers.they have big e clips holding them in place.adjuster has been replaced once already but buddy of mine did last time.i have been spraying ball joints twice a day with aerokroil for about 4 days now.we ll c if knuckle will budge or not.

Last edited:

- Joined

- Mar 6, 2020

- Messages

- 1,815

- City

- 48022

- State - Country

- MI - USA

- Vehicle Year

- 1994

- Vehicle

- Ford Ranger

- Engine

- 4.0 V6

- Transmission

- Automatic

- Total Lift

- 1-1/2 inch front leveling

- Total Drop

- Stock

- Tire Size

- 31/10.50/15

- My credo

- What's the worst that could happen?

Well you are right about hitting it hard enough with the hammer to drop the knuckle, but removing the adjuster bushing without removing the knuckle from the ball joints would be difficult at best. Again, not familiar with the 4x2 set-up.

Similar threads

- Replies

- 3

- Views

- 953

- Replies

- 7

- Views

- 3K

- Replies

- 2

- Views

- 161

- Replies

- 0

- Views

- 154

Sponsored Ad

Sponsored Ad

TRS Events

Latest posts

-

-

-

My Koppla Gator cruiser electric motorcycle battery caught fire =(

- Latest: 2011Supercab

-

-

-

-

-