Since my Bronco is coming along slower than I hoped, I will post the rebuild guide early. I even borrowed a camera for this. It is just a normal R1/R1 build.

--------------------------------------------

This is meant to be a supplement to the tech library packet

here.

For this swap you will need your 4.0L OHV transmission and a suitable donor. To be safe, any pre-2000 4wd will work. There are others that are likely compatible suggested in the tech library. I chose a 1997 3.0L 4wd.

Difficulty: 7/10 You will need specialty tools, including precision measurement devices and be able to read some complex instructions from the manual.

Tools: torque wrench, snap ring pliers, bearing splitter, torch/oven, press, measurement tools (calipers okay, micrometers best), mallet, 55mm capable wrench, new collar nuts, beer

Time: Day for a first timer, 4 hours if you know what you are doing.

Disclaimer: The Ranger Station.com, The Ranger Station.com Staff, nor the original poster are responsible for you doing this modification to your vehicle. By doing this modification and following this how-to you, the installer, take full responsibility if anything is damaged or messed up. If you have questions, feel free to PM the original poster or ask in the appropriate section of The Ranger Station.com forums.

====disassembly====

Before starting the swap get yourself a clean, well lit working surface. Clean both of the transmission cases and drain the fluid. When you break the tail housing off make sure to use a torch and rock the bolts back and forth with plenty of PB or similar. The bolts will very easily take the aluminum threads with them.

The first tricky part of the disassembly is the rear collar nuts. I found the best way to break them off is to lay the transmission on the floor and sit on the bell housing. Put the wrench tightly on the nut and smack it off with the mallet.

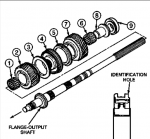

As you follow the guide to take the transmission apart, its best practice to arrange the parts in a clear order to make assembly easy. I chose to place the components in a way where they tip towards the center of the transmission.

The rear main bearing removal is the most risky part of the whole procedure and can easily cause damage to the reverse gear. I break away from the manual here to prevent the needing a $300 specialty tool. On the side of the transmission is a 12mm bolt that holds in the 5th/reverse shaft. Undo that and pull the shaft out being mindful of the detent ball and spring. This allows you to get a regular bearing splitter with some thin wood shims behind the bearing to pull it off.

The innermost item before the center countershaft bearing is a spacer with a ball bearing in it. Be careful or it will roll under your workbench!

Once the center and front bearing caps are removed, wiggle the shafts front to back to help slide the bearings off of the countershaft. This makes it easier to pull the main shaft apart. Be careful with the front cover. It contains multiple seals and shims.

At this point, if your transmission is in known good shape, you could skip right to the assembly part. I got my donor off the shelf from the junk yard and wanted to be sure everything was alright. The pic below shows why that was a good idea.

Undo the third gear snap ring and set and everything behind it aside. Set up your press with wood to protect second gear and press the shaft out of the remaining gears. Be sure to catch the shaft; there is a bearing surface on the end that hits the ground first!

Once it is all apart it is time to clean everything. The case should be clean, the oil passages in the main shaft shot with parts cleaner, and the inside of the spacers cleared of metal shavings. Clean out the front oil pump by shooting it with cleaner and the collector in the tail housing pulls straight out. The oil funnel likes to collect bits of the synchros before it goes to the front bearings. Ensure the case mating surfaces are completely free of RTV.

Once everything is clean and apart it is time to take stock of what you have. Look for the best bearings and select gears that show no signs of wear. It is best practice to keep gears that mesh together as a set. Feel the input and output shaft where the main seals rest with a finger nail. Select the shaft with the smallest groove. Look at the shift forks and pick the ones with the most meat left. If you are reusing sychros, Ford provides no official wear measuring procedure. I believe measuring how far the synchro rides up the taper to be sufficient.

For ID purposes here is what main shaft gear has what teeth:

Gear | 4.0L | Other |

1 | 36 | 35 |

2 | 32 | 31 |

3 | 29 | 27 |

4 | 23 | 23 |

====reassembly====

To put the bearings back on the shaft without special tools, lightly heat them and slip them on. They do not need to be smoking to fit on. Lightly tap the inner race to make sure its seated. The third gear thrust bearing and spacer must fit behind the snap ring! If it does not, the gear is not properly seated.

Install the three shafts into the case with no bearings. Install the center bearings first. Place the races into their holes half way and use the retainer to pull them into place, sneaking up on it by turning all the bolts a little bit at a time. Stand the transmission up on some wood to install the front bearings. Tap them in as far as they will go and measure how far they stick out. Verify the shims you have are correct by referencing the shop manual for measurement procedure.

Clean the front surface with parts cleaner and apply a VERY LIGHT layer of RTV on the sealing surface and bolt threads. Below are pictures of what too much RTV can do:

The oiling passages are nearly clogged.

Put the 5th/reverse shift fork back on the shaft before reinstalling. Use a small punch to hold down the detent ball. The big nut on the output shaft can just be smacked to approximate torque and pinned on with a chisel. When installing the tail shaft bolts, make sure to anti-seize the threads to prevent further damage to the case.

Congratulations! You now have a 4.0L transmission with better gearing.