Contributed By: Louis Schilling

This is the text, and photos for solving the problem of lost turning radius after installing lift spindles on late model 2wd Rangers

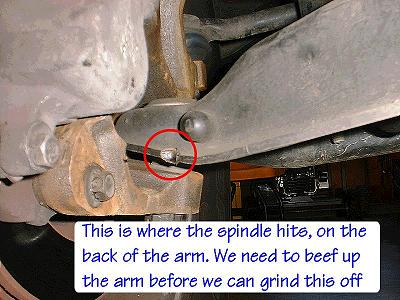

You need to clearance either the spindle, or the lower control arm. I don’t suggest you grind the spindle, one reason is it’s hard to get any strength back, so we should clearance the lower arm. You can clearance the arm with a grinder, then weld a plate to the arm to get back some strength back.

Start with a cardboard pattern, like the photo, and transfer the shape to some metal, I used .125″ thick 4130 Chrome-Moly steel plate, but you can use 187″ thick cold rolled mild steel.

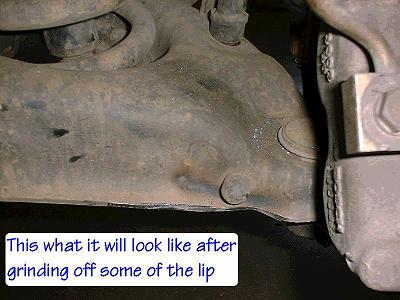

Turn the spindle all the way to both the right and left, noting where the spindle hits the lower arm. now you need to grind away the lip that sticks out from the lower arm sides. after grinding, go back with a sander and polish down any grind marks, remember – sharp metal tends to crack.

Now start fitting the doubler plate to the lower arm, this is where we pick up the strength we lost from grinding the lip. After getting a good fit, weld it on, I TIG (Heli-Arc) welded mine, but you can MIG (Wire Weld) yours also. A good muffler shop can usually MIG weld it for you if you have no access to a welder. I welded one pass on one arm, then did one pass on the other arm, this kept the heat down to keep from possibly cooking the lower ball joint.

Paint and start turning again!

About The Author

Jim Oaks is the founder of TheRangerStation.com, the longest-running Ford Ranger resource online since 1999. With over 25 years of hands-on experience building and modifying Ford Rangers — including magazine-featured builds like Project Transformer — Jim has become one of the most trusted authorities in the Ford Ranger off-road and enthusiast space.

Since launching TheRangerStation.com, Jim has documented thousands of real-world Ranger builds, technical repairs, drivetrain swaps, suspension modifications, and off-road adventures contributed by owners worldwide. TheRangerStation.com has been referenced in print, video and online by enthusiasts, mechanics, and off-road builders looking for practical, and experience-based information.