File / Grind Ring Gear Tooth For Cross Pin Clearance

When installing a ‘Lunchbox Locker’ such as a Lock-Right Locker in an axle with numerically higher gears (4.10, 4.56, 4.88, etc.) you may find that the locker cross pin cannot be inserted because into the locker because it won’t clear one of the teeth on the ring gear. You CANNOT use a notched cross pin with a lunchbox locker (AKA Drop In Locker).

Notched pins can interfere with the ramping action of the locker. The Lock-Right relies on the cross pin to push against the internal drivers to engage or disengage the teeth; a notch provides an uneven surface that can cause the locker to bind or fail to operate smoothly.

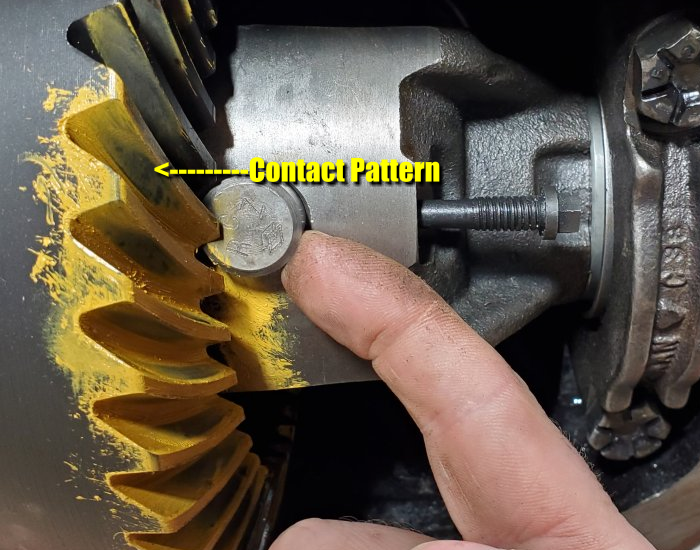

The solution is to file or grind the tips of one or two ring gear teeth (outside the contact pattern) just enough to slide a standard pin through.

Making It Fit

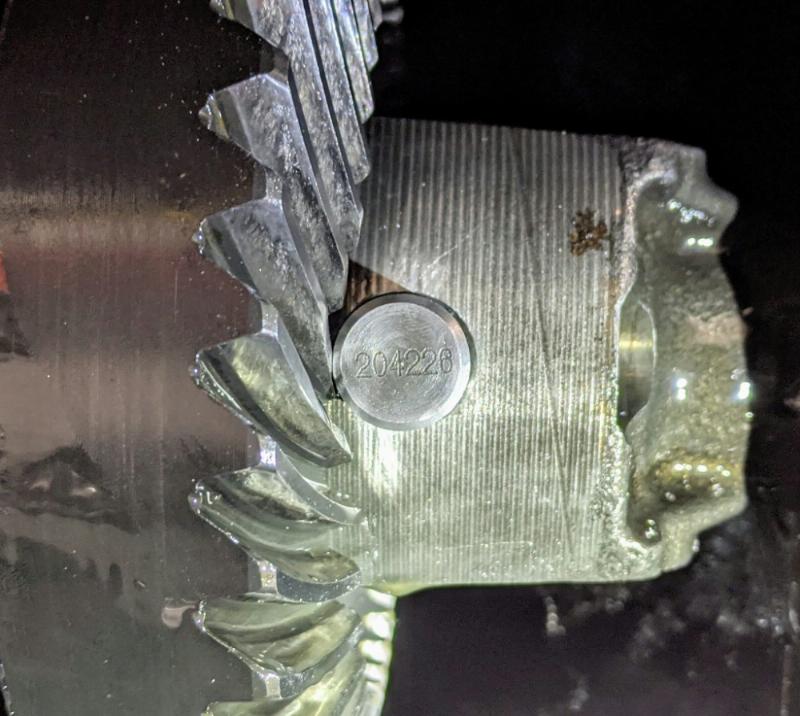

In the photos below you can see where the cross pin hits the gear tooth when you try push it through the locker. You can also see the contact pattern where the ring gear makes contact with the pinion gear. You don’t want to grind into this area. The second photo shows the other side of the differential, and these were the teeth that forum member ‘ecgreen’ chose to grind. The third photo shows the area that was ground, and the fourth photo shows the cross pin being able to fit through.

The edge of the gear tooth doesn’t take any load from the pinion.

Does Grinding a Tooth Weaken it?

Grinding a ring gear tooth does not significantly weaken the gear as long as it is done correctly. It is a common procedure when installing deep gear ratios (like 4.56 or 4.88) to allow the cross pin to clear the ring gear.

Here are the key factors for a safe grind:

Stay Outside the Contact Pattern: You only need to grind a small amount (typically about the size of a pencil eraser) from the toe or heel of the tooth. Because the pinion does not make contact with these extreme edges, removing this material has no impact on the gear’s operating strength.

Minimize Material Removal: Only remove enough material to allow the cross pin to slide in or out. Typically, only one to three teeth need a slight trim.

Avoid Overheating: Use a Dremel or a small hand grinder with a sanding roll rather than a heavy bench grinder to avoid excessive heat buildup. Excessive heat can anneal the metal, soften the heat-treated surface and potentially cause premature wear or cracks.

Remove Burrs: After grinding, use a fine-grit sandpaper or a 3M scotch disc to round the edges and remove any sharp burrs that could break off and contaminate the oil.

Prevent Contamination: Perform the grinding with the gear outside the housing if possible. If the carrier is already installed, mask off the area thoroughly and use magnets or a vacuum to ensure no metal shards remain in the differential.

Caution: While grinding a gear tooth is safe, you should never grind the cross pin itself when using a Lock-Right locker. Doing so can create an “escape route” for the locker’s internal springs, leading to a catastrophic failure of the unit.

Tips For Keeping Debris Out of The Locker

Pack the area around the differential with rags and place a shop vac next to the area you’re grinding.

Discussion

4.56 gears in a 7.5 with a lockrite | The Ranger Station

About The Author

Jim Oaks is the founder of TheRangerStation.com, the longest-running Ford Ranger resource online since 1999. With over 25 years of hands-on experience building and modifying Ford Rangers — including magazine-featured builds like Project Transformer — Jim has become one of the most trusted authorities in the Ford Ranger off-road and enthusiast space.

Since launching TheRangerStation.com, Jim has documented thousands of real-world Ranger builds, technical repairs, drivetrain swaps, suspension modifications, and off-road adventures contributed by owners worldwide. TheRangerStation.com has been referenced in print, video and online by enthusiasts, mechanics, and off-road builders looking for practical, and experience-based information.