4x4prepper

Active Member

- Joined

- Feb 2, 2015

- Messages

- 507

- Reaction score

- 216

- Points

- 43

- Location

- Atlanta

- Vehicle Year

- 1985

- Make / Model

- Ford

- Transmission

- Manual

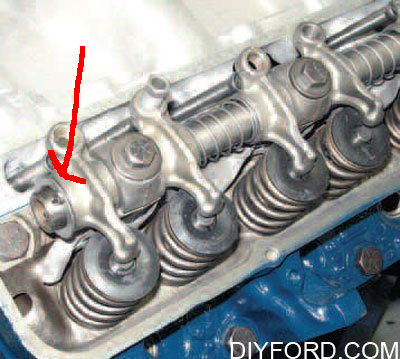

I took off my valve cover hoping the reseal would stop a leak and found a broken wave washer sitting on the head, never had that happen before. It looks like the pedestal has moved, it appears the washer/spacer folds around the cotter pin and provides tension is the pedestal does not turn and move back and forth. Here is a picture of one for a FE 390. Since I can not find out the part number, I have no way of trying to find NOS or a replacement.

Someone asked how did I block the EGR hole, I guess I just bolted a piece of scrap metal over the hole.

Here is a picture of a 1974/1975 intake manifold on a 2.8L I rebuilt, for reference.

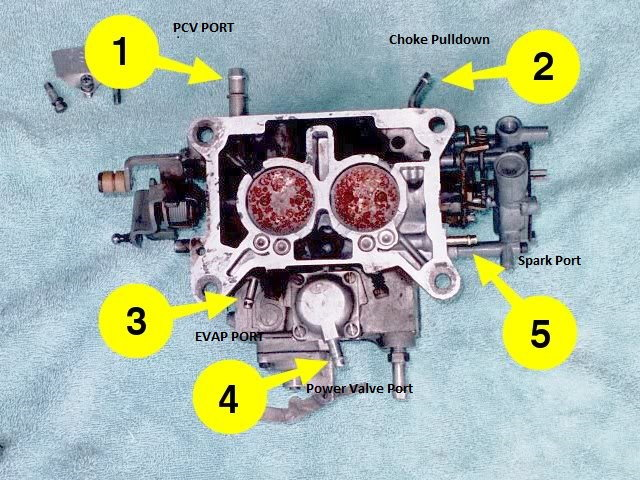

In the carb picture you can see a port blocked off by the accel pump. After reading the posts about the power valve port I decided to test it just to make sure it was not a power valve port because I thought it was internal on this carb. So, at idle it makes 0 and when you hit the throttle it pulls about 10 Hg. So, it is the emissions port to pull from the charcoal canister as far as I can tell. I hooked it up to manifold vacuum and went for a quick spin. The B2 drove better. I think with however the internals are set up in the carb, if that port does not pull air in, it upsets the metering by having it blocked off. I need to tow my trailer under load up hill to be sure it just was not my imagination that it felt like more power. Maybe with just a fuel filter attached to the port and see how it does.

Someone asked how did I block the EGR hole, I guess I just bolted a piece of scrap metal over the hole.

Here is a picture of a 1974/1975 intake manifold on a 2.8L I rebuilt, for reference.

In the carb picture you can see a port blocked off by the accel pump. After reading the posts about the power valve port I decided to test it just to make sure it was not a power valve port because I thought it was internal on this carb. So, at idle it makes 0 and when you hit the throttle it pulls about 10 Hg. So, it is the emissions port to pull from the charcoal canister as far as I can tell. I hooked it up to manifold vacuum and went for a quick spin. The B2 drove better. I think with however the internals are set up in the carb, if that port does not pull air in, it upsets the metering by having it blocked off. I need to tow my trailer under load up hill to be sure it just was not my imagination that it felt like more power. Maybe with just a fuel filter attached to the port and see how it does.