overloaded

New Member

- Joined

- Aug 6, 2014

- Messages

- 10

- Reaction score

- 0

- Points

- 1

- Vehicle Year

- 2004

- Make / Model

- Ford

- Transmission

- Automatic

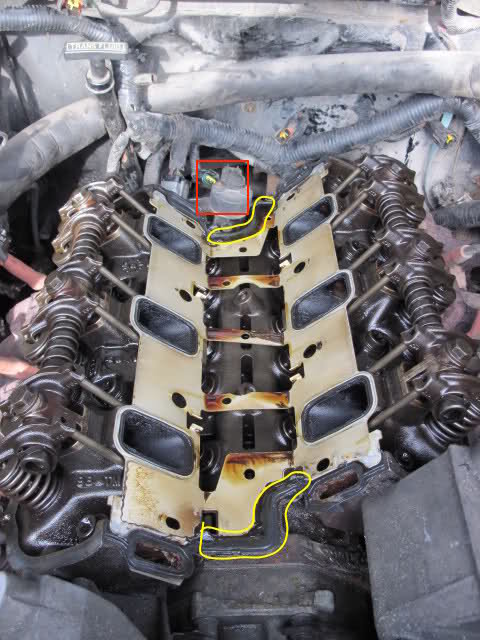

I replaced my head gaskets(valve seats finally wore out, lost compression, got the heads decked/seats replaced with the updated hardened ones), both the lower and upper intake gaskets, and the valve cover gaskets back in July, and after driving a few thousand miles post-repair I heard a loud POP noise, noticed that my coolant was disappearing quickly, and then cylinder #3 started misfiring. I pulled the manifold off and discovered the rubber portion of the gasket on the lower manifold had popped out right where the crankshaft position synchronizer/sensor sits, and that the fiber gasket had started eroding between the coolant and intake passage, allowing a small amount of leakage at certain temperatures which caused the misfire. I thought I had followed the torque specs and bolt order found in the Tech Library here correctly(it's not exactly a difficult job to do), and I had made sure to RTV the gaps+let it sit 24 hours before cranking the engine again. But, since that was my first time doing this particular job I assumed I had done something wrong in the process and replaced it with a new gasket set, torqued it down in sequence a few extra ft-lbs(I think it was to 28) for good measure(in case my torque wrench was more than the expected 2% off of the indicated value) and started driving around normally.

A few days ago, it made that same POP noise again, and I'm leaking oil like crazy from the rear with no misfire problems yet. I took a look by the crank synchro and lo and behold, the new gasket looks to have popped out in the same spot again. And I'm certain that on the second time I followed the instructions, as written, correctly. So what am I doing wrong here? There wasn't mention of needing to use loc-tite or anything when I read over instructions, and referring to a copy of the ford service manual I got ahold of doesn't mention using any loc-tite or similar thread treatment, so loc-tite was not applied. No mention in the literature of needing to re-torque after a certain amount of miles due to heat cycling either, so I hadn't performed anything like that.

Should I actually be re-torquing after X miles or using loc-tite? I haven't pulled the upper manifold off yet to check if the bolts loosened up, but I have a feeling they did. Alternately, is this a good indication that I've got something else wrong that I'm not thinking of? I would have figured that if there was a stuck valve or similar item not opening and causing an overpressure situation it would have blown almost immediately. While the first time I pulled the manifold off was nearly 6 months ago, I don't remember seeing any sort of coating on the bolts, and the original gasket made it to 200,000+ without having any problems. I also don't want to just start slapping loc-tite on where it doesn't belong, and then have it contaminate and bind up something important inside the cam/lifter area and possibly make things worse.

There's got to be something I'm missing here, I used the Fel-Pro set (MS953721) both times and I've never had Fel-Pros just blow out like this whenever I've changed other gaskets before(and with some of the first ones, I definitely did not bother with any form of torque spec past the classic German standby of "gutentight"). I've replaced every gasket on this engine save for the rear main seal by now and this is the only one I've ever had a problem with, so the problem's got to be me.

Help? I'd really like to solve this problem for good, gasket sets are only $16 but I'd rather not have to spend another random weekend or weeknight replacing the stupid thing again, on top of the fact that leaking 5w20 all over the place is no good for anybody.

edit: clarified a few details

A few days ago, it made that same POP noise again, and I'm leaking oil like crazy from the rear with no misfire problems yet. I took a look by the crank synchro and lo and behold, the new gasket looks to have popped out in the same spot again. And I'm certain that on the second time I followed the instructions, as written, correctly. So what am I doing wrong here? There wasn't mention of needing to use loc-tite or anything when I read over instructions, and referring to a copy of the ford service manual I got ahold of doesn't mention using any loc-tite or similar thread treatment, so loc-tite was not applied. No mention in the literature of needing to re-torque after a certain amount of miles due to heat cycling either, so I hadn't performed anything like that.

Should I actually be re-torquing after X miles or using loc-tite? I haven't pulled the upper manifold off yet to check if the bolts loosened up, but I have a feeling they did. Alternately, is this a good indication that I've got something else wrong that I'm not thinking of? I would have figured that if there was a stuck valve or similar item not opening and causing an overpressure situation it would have blown almost immediately. While the first time I pulled the manifold off was nearly 6 months ago, I don't remember seeing any sort of coating on the bolts, and the original gasket made it to 200,000+ without having any problems. I also don't want to just start slapping loc-tite on where it doesn't belong, and then have it contaminate and bind up something important inside the cam/lifter area and possibly make things worse.

There's got to be something I'm missing here, I used the Fel-Pro set (MS953721) both times and I've never had Fel-Pros just blow out like this whenever I've changed other gaskets before(and with some of the first ones, I definitely did not bother with any form of torque spec past the classic German standby of "gutentight"). I've replaced every gasket on this engine save for the rear main seal by now and this is the only one I've ever had a problem with, so the problem's got to be me.

Help? I'd really like to solve this problem for good, gasket sets are only $16 but I'd rather not have to spend another random weekend or weeknight replacing the stupid thing again, on top of the fact that leaking 5w20 all over the place is no good for anybody.

edit: clarified a few details

Last edited: