- Joined

- Jul 6, 2008

- Messages

- 259

- Reaction score

- 78

- Points

- 28

- Location

- Monument, CO

- Vehicle Year

- 1991

- Make / Model

- Ford

- Engine Size

- 4.0

- Transmission

- Manual

Back to work on the ranger today. Actually, on a few rangers.

I went to the junkyard first. Spent most of the morning pulling off upper intakes to get a good set of valve covers. Mine are pretty ugly from the poor repaint job I did. I was also missing a plastic piece and I wanted to start over. I tried popping out the plastic piece but it was no go. Ended up busting it and the bracket. So I went on the hunt for a good used set of valve covers.

Ran accross this beauty. First one in a u pull I have ever seen.

The other reason I was searching was that I thought the oil pump drive gear must be different on the 98-2000 engines- because my drive would not go into the 98 engine like it did in my 1991.

So I started with a 1993, removing the valve covers. I also was hoping to get the wiring harness that goes to the injectors and oil pressure sensor etc. Mine was in bad shape when I removed it- though functional.

Turns out the 1993 was a little different. And by the time I got to the drivers valve cover I noticed it had some broken plastics.

On to the next. I pulled a 1991 to get the wiring. Got the upper intake off to realize the wiring had been hacked and someone had redone the coolant sensors separately.

Next I moved to a 1998 to get the oil pump gear out. I ended up taking it all the way down and even taking off the lower intake to get it out. The later engines have a sensor on there.

They look a little different. I mic'd everything and the longer end is the only difference I could find. That shouldn't matter if I use the same shaft.

Turns out it took a little bit of firm force to get the new one in, and this gave me the confidence to push the 1991 in firmly and it was fine. All that for nothing but a little knowledge I guess. I did also order a new O-Ring from Ford. $10 is good insurance to make sure it doesn't leak.

Between cleaning the new valve covers and painting them I started to take apart the timing cover and water pump. With my luck one of the bolts snapped.

I did the old weld a nut to it trick and it came out easy enough.

I stopped on that because I need a puller for the pulley. I wish it was in better shape. Ill see if a new one can be had. So I yanked the oil pan and began the cleanup process on it. I am getting better at cleaning this stuff but it is nasty.

Ended the day with a coat of paint on my new valve covers and on the @Brian1 supports. Stoked to get them installed.

Autozone has this high temp enamel paint in Ford Grey. I am going to paint it all that color. Love the stock color.

I also did find a way to install the plastic spark plug guides. I cut the metal with a grinder- which heats up the plastic. Then I twist the metal to breaking point and the plastic falls out without breaking- partially from the heat. Then I can pop into the new set.

Finished off the day by ordering the parts to do a saginaw power steering pump conversion. Thanks to @Gmanpaint for the inspiration. I was already planning to do new hoses anyway. Might as well do this too.

Pulley from PSC for higher volume at idle: https://www.pscmotorsports.com/psc-pp2401.html

Proquipped bracket for conversion: https://proquipped.com/shop/ols/products/p1-adapter-kit

I am going to call the dealer and see what my price is on a new mopar pump tomorrow. Need a 2006 Jeep liberty v6 pump.

I went to the junkyard first. Spent most of the morning pulling off upper intakes to get a good set of valve covers. Mine are pretty ugly from the poor repaint job I did. I was also missing a plastic piece and I wanted to start over. I tried popping out the plastic piece but it was no go. Ended up busting it and the bracket. So I went on the hunt for a good used set of valve covers.

Ran accross this beauty. First one in a u pull I have ever seen.

The other reason I was searching was that I thought the oil pump drive gear must be different on the 98-2000 engines- because my drive would not go into the 98 engine like it did in my 1991.

So I started with a 1993, removing the valve covers. I also was hoping to get the wiring harness that goes to the injectors and oil pressure sensor etc. Mine was in bad shape when I removed it- though functional.

Turns out the 1993 was a little different. And by the time I got to the drivers valve cover I noticed it had some broken plastics.

On to the next. I pulled a 1991 to get the wiring. Got the upper intake off to realize the wiring had been hacked and someone had redone the coolant sensors separately.

Next I moved to a 1998 to get the oil pump gear out. I ended up taking it all the way down and even taking off the lower intake to get it out. The later engines have a sensor on there.

They look a little different. I mic'd everything and the longer end is the only difference I could find. That shouldn't matter if I use the same shaft.

Turns out it took a little bit of firm force to get the new one in, and this gave me the confidence to push the 1991 in firmly and it was fine. All that for nothing but a little knowledge I guess. I did also order a new O-Ring from Ford. $10 is good insurance to make sure it doesn't leak.

Between cleaning the new valve covers and painting them I started to take apart the timing cover and water pump. With my luck one of the bolts snapped.

I did the old weld a nut to it trick and it came out easy enough.

I stopped on that because I need a puller for the pulley. I wish it was in better shape. Ill see if a new one can be had. So I yanked the oil pan and began the cleanup process on it. I am getting better at cleaning this stuff but it is nasty.

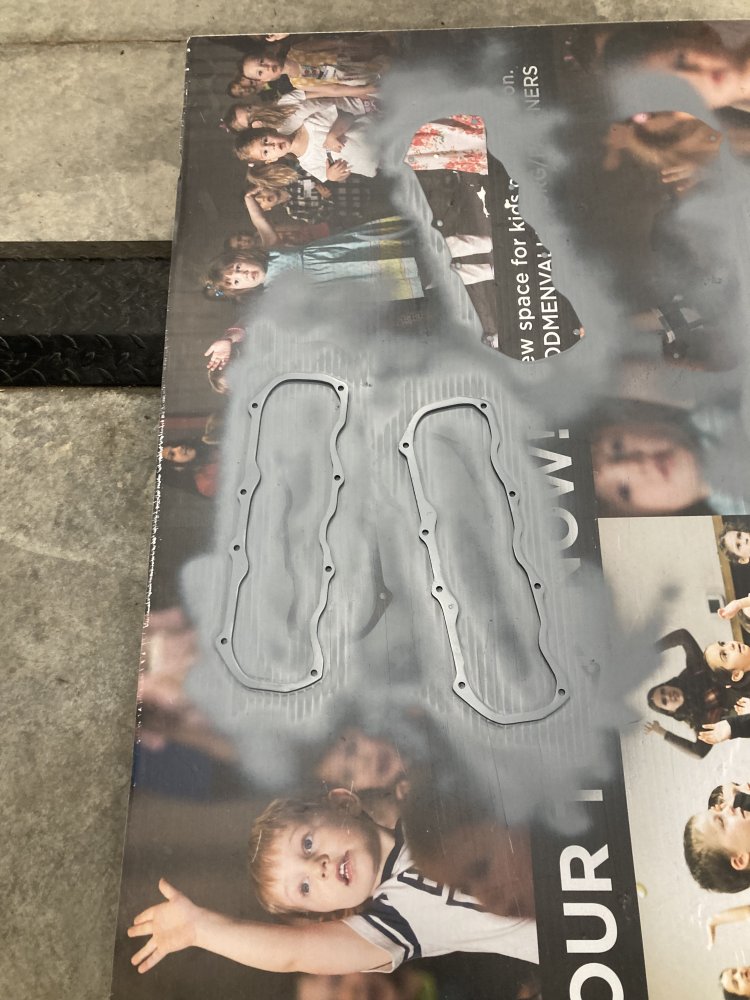

Ended the day with a coat of paint on my new valve covers and on the @Brian1 supports. Stoked to get them installed.

Autozone has this high temp enamel paint in Ford Grey. I am going to paint it all that color. Love the stock color.

I also did find a way to install the plastic spark plug guides. I cut the metal with a grinder- which heats up the plastic. Then I twist the metal to breaking point and the plastic falls out without breaking- partially from the heat. Then I can pop into the new set.

Finished off the day by ordering the parts to do a saginaw power steering pump conversion. Thanks to @Gmanpaint for the inspiration. I was already planning to do new hoses anyway. Might as well do this too.

Pulley from PSC for higher volume at idle: https://www.pscmotorsports.com/psc-pp2401.html

Proquipped bracket for conversion: https://proquipped.com/shop/ols/products/p1-adapter-kit

I am going to call the dealer and see what my price is on a new mopar pump tomorrow. Need a 2006 Jeep liberty v6 pump.