Shran

Junk Collector

TRS Forum Moderator

Supporting Member

Article Contributor

V8 Engine Swap

Solid Axle Swap

Truck of Month

- Joined

- Mar 4, 2008

- Messages

- 8,698

- Reaction score

- 4,798

- Points

- 113

- Location

- Rapid City SD

- Engine Type

- V8

- Engine Size

- 5.0

I thought I'd share some thoughts about my SAS, since it has been done for almost two years and I've had time to work the bugs out of it.

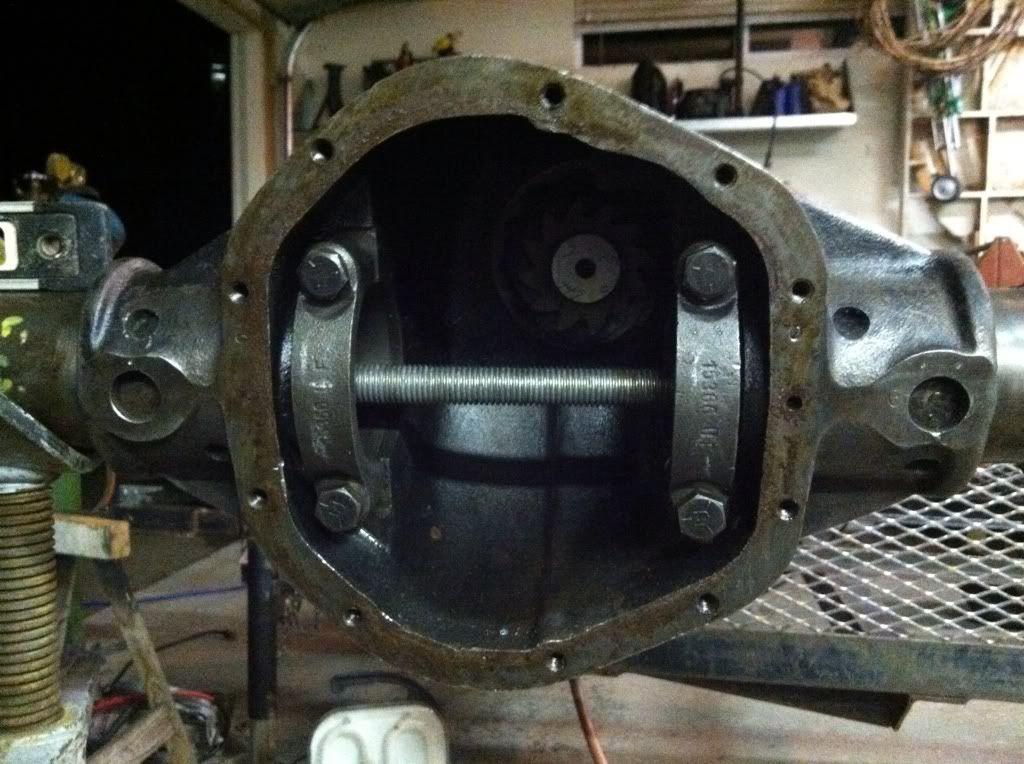

First and foremost. Everyone, literally everyone, seems to have this idea that the Early Bronco D44 is THE axle to have, if you want to stay "RBV width." I will tell you, it is not. It is simply impossible to get a reasonable pinion angle AND have reasonable caster measurements AND any amount of lift. Pick one and throw the other two out the window because it won't happen without turning the C's and/or wedgies on the housing.

If you REALLY must have a D44, you NEED a high pinion housing. You also need 76-77 Early Bronco knuckles because the steering arms are literally like almost 1.5" higher than the F150 version. I highly recommend building your own steering from DOM and heims vs tie rod ends. I did that, and used a narrowed and sleeved F150 track bar. My truck with 35's, 6ish inches of lift and a redneck alignment drives so smooth that I can do 80 with no wandering, no death wobble, and I do not even have a steering stabilizer!

Secondly, and this is pretty obvious, make an axle shaft upgrade a priority if you do ANY kind of wheeling. If you end up with stock Early Bronco axle shafts, like I did, buy good (Spicer) u-joints or you will be making a trip to the parts store to warranty at least one u-joint after every trip out. The F150 axle shafts are significantly better and I actually only broke a u-joint in these once. A good set of hardened shafts is only like $500 and it's a HUGE upgrade to your truck and confidence level.

Third, make lockout hub purchases the last item on your list unless you have something that is known garbage. I had the stock Ford (actually Spicer, I believe) lockouts in my truck and they went through some serious abuse without a single hiccup. Most people want the hubs to be the "fuse," ie part that breaks first and is easiest to repair - but the Ford lockouts IMO are so strong that there is zero reason to replace them with anything else. I am referring to the style with the huge spring and two separate, cast steel pieces that fit over each other and interlock, NOT the "Warn" style that have a small "gear" thing inside a larger piece.

The one other piece of not-so-well-known tech I'd like to share involves polyurethane C-bushings (ie Energy Suspension, Duff, parts store brands, etc.) They are CRAP CRAP CRAP!!! Mine were cracked and blown out of the radius arm within 200 miles and 4-5 very mild wheeling trips, leaving the axle to rotate wildly inside the bushings. In talking with a few local people, I learned that it's pretty common for this to happen because the poly bushings don't "flex" at all, so something has to give. They are probably fine for on-road driving, and I would for sure run them without hesitation in that situation but for any offroad vehicle, rubber is the ONLY way to go. NAPA has rubber bushings and they are cheap and awesome.

Hope this helps someone avoid a bunch of extra work. I could have avoided doing things 3-4 times if I had known some of this stuff.

First and foremost. Everyone, literally everyone, seems to have this idea that the Early Bronco D44 is THE axle to have, if you want to stay "RBV width." I will tell you, it is not. It is simply impossible to get a reasonable pinion angle AND have reasonable caster measurements AND any amount of lift. Pick one and throw the other two out the window because it won't happen without turning the C's and/or wedgies on the housing.

If you REALLY must have a D44, you NEED a high pinion housing. You also need 76-77 Early Bronco knuckles because the steering arms are literally like almost 1.5" higher than the F150 version. I highly recommend building your own steering from DOM and heims vs tie rod ends. I did that, and used a narrowed and sleeved F150 track bar. My truck with 35's, 6ish inches of lift and a redneck alignment drives so smooth that I can do 80 with no wandering, no death wobble, and I do not even have a steering stabilizer!

Secondly, and this is pretty obvious, make an axle shaft upgrade a priority if you do ANY kind of wheeling. If you end up with stock Early Bronco axle shafts, like I did, buy good (Spicer) u-joints or you will be making a trip to the parts store to warranty at least one u-joint after every trip out. The F150 axle shafts are significantly better and I actually only broke a u-joint in these once. A good set of hardened shafts is only like $500 and it's a HUGE upgrade to your truck and confidence level.

Third, make lockout hub purchases the last item on your list unless you have something that is known garbage. I had the stock Ford (actually Spicer, I believe) lockouts in my truck and they went through some serious abuse without a single hiccup. Most people want the hubs to be the "fuse," ie part that breaks first and is easiest to repair - but the Ford lockouts IMO are so strong that there is zero reason to replace them with anything else. I am referring to the style with the huge spring and two separate, cast steel pieces that fit over each other and interlock, NOT the "Warn" style that have a small "gear" thing inside a larger piece.

The one other piece of not-so-well-known tech I'd like to share involves polyurethane C-bushings (ie Energy Suspension, Duff, parts store brands, etc.) They are CRAP CRAP CRAP!!! Mine were cracked and blown out of the radius arm within 200 miles and 4-5 very mild wheeling trips, leaving the axle to rotate wildly inside the bushings. In talking with a few local people, I learned that it's pretty common for this to happen because the poly bushings don't "flex" at all, so something has to give. They are probably fine for on-road driving, and I would for sure run them without hesitation in that situation but for any offroad vehicle, rubber is the ONLY way to go. NAPA has rubber bushings and they are cheap and awesome.

Hope this helps someone avoid a bunch of extra work. I could have avoided doing things 3-4 times if I had known some of this stuff.

I suggest heims (where they are legal) because to me it's easier to fabricate a steering setup that works really well instead of messing around with factory steering components. It's also less work because you don't have to find or buy a reamer if you want to do the GM 1-ton TRE upgrade. I'm not saying TREs are a bad choice, heims just seem far easier in my experience.

I suggest heims (where they are legal) because to me it's easier to fabricate a steering setup that works really well instead of messing around with factory steering components. It's also less work because you don't have to find or buy a reamer if you want to do the GM 1-ton TRE upgrade. I'm not saying TREs are a bad choice, heims just seem far easier in my experience.