aball4620

Member

- Joined

- May 13, 2020

- Messages

- 62

- Reaction score

- 3

- Points

- 8

- Location

- Seattle

- Vehicle Year

- 1988

- Make / Model

- Ford Ranger

- Engine Type

- 2.9 V6

- Transmission

- Automatic

- 2WD / 4WD

- 4WD

So this project has been a fun - if not frustrating - learning experience. I replaced the heads with new several months ago after blowing and injector o-ring. I thought I maybe had a small head gasket leak, and the '88 2.9 was still prone to cracking. Put it all back together and doesn't run well. I finally took it into a mechanic to have some diagnostics run and he is as confused as I am. I'm attaching the cylinder wave form readings here for your thoughts. I'm also developing a working theory as to why things are not functioning correctly and I wanted some feedback. Current symtoms are hunting while idling and not wanting to rev above 2k. Will barely move and certainly isn't driveable. No codes. Every - and I do mean every - component of the fuel system has been checked and tested. All sensors are new and confirmed working. The ECM is confirmed working and has been tested.

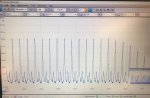

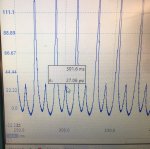

New heads, gaskets, lifters, pushrods, etc. Top end rebuild. Also a new distributor, coil, wires, plugs, etc. Everything has been done correctly and confirmed both through this forum, Chilton, Haynes, and then finally by my mechanic. This thing has always run rich and always been a little gutless. There has almost always been a little wispy white smoke out of the back even though I wasn't losing coolant. Or at least not quickly. The guy I bought this from was an absolute hack and I first noticed that when I blew a fuel line between the reservoir and the rail pump because he had forced the wrong size clip on backwards. So with the rebuild the timing was set at 10 degrees advance, the harmonic balancer confirmed attached correctly, and the new distributor and ignition module checked, and rechecked, and rechecked. The mechanic thinks that cam timing was maybe off before tearing into it and I didn't catch it. Didn't even occur to me to check the timing before the tear down. And that with reassembly we're seeing that 27 psi on the exhaust stroke, meaning that both valves are closed and creating the back pressure that is keeping this thing from revving correctly. For what it is worth, he was pretty sure it was a plugged cat/exhaust before pulling it off to realize it had been knocked out years ago. Unplugging the o2 sensor changes nothing. The mechanic is stumped and he thinks the only logical next step is to install a new timing chain correctly (might as well do the water pump while I'm in there). What do you think? He's excited for me to tear this thing apart again and take pictures.

My working theory is that the PO replaced the timing chain but didn't do it correctly, and then fiddled with the timing advance to get it to run. Me, having installed a new distributor, covered up the tracks in the snow by doing it correctly as the book says. All of the other issues I've had over the last couple years could be because of the cam not being timed to the crank correctly.

New heads, gaskets, lifters, pushrods, etc. Top end rebuild. Also a new distributor, coil, wires, plugs, etc. Everything has been done correctly and confirmed both through this forum, Chilton, Haynes, and then finally by my mechanic. This thing has always run rich and always been a little gutless. There has almost always been a little wispy white smoke out of the back even though I wasn't losing coolant. Or at least not quickly. The guy I bought this from was an absolute hack and I first noticed that when I blew a fuel line between the reservoir and the rail pump because he had forced the wrong size clip on backwards. So with the rebuild the timing was set at 10 degrees advance, the harmonic balancer confirmed attached correctly, and the new distributor and ignition module checked, and rechecked, and rechecked. The mechanic thinks that cam timing was maybe off before tearing into it and I didn't catch it. Didn't even occur to me to check the timing before the tear down. And that with reassembly we're seeing that 27 psi on the exhaust stroke, meaning that both valves are closed and creating the back pressure that is keeping this thing from revving correctly. For what it is worth, he was pretty sure it was a plugged cat/exhaust before pulling it off to realize it had been knocked out years ago. Unplugging the o2 sensor changes nothing. The mechanic is stumped and he thinks the only logical next step is to install a new timing chain correctly (might as well do the water pump while I'm in there). What do you think? He's excited for me to tear this thing apart again and take pictures.

My working theory is that the PO replaced the timing chain but didn't do it correctly, and then fiddled with the timing advance to get it to run. Me, having installed a new distributor, covered up the tracks in the snow by doing it correctly as the book says. All of the other issues I've had over the last couple years could be because of the cam not being timed to the crank correctly.

Attachments

-

190.3 KB Views: 107

-

249.1 KB Views: 111

-

143.2 KB Views: 113