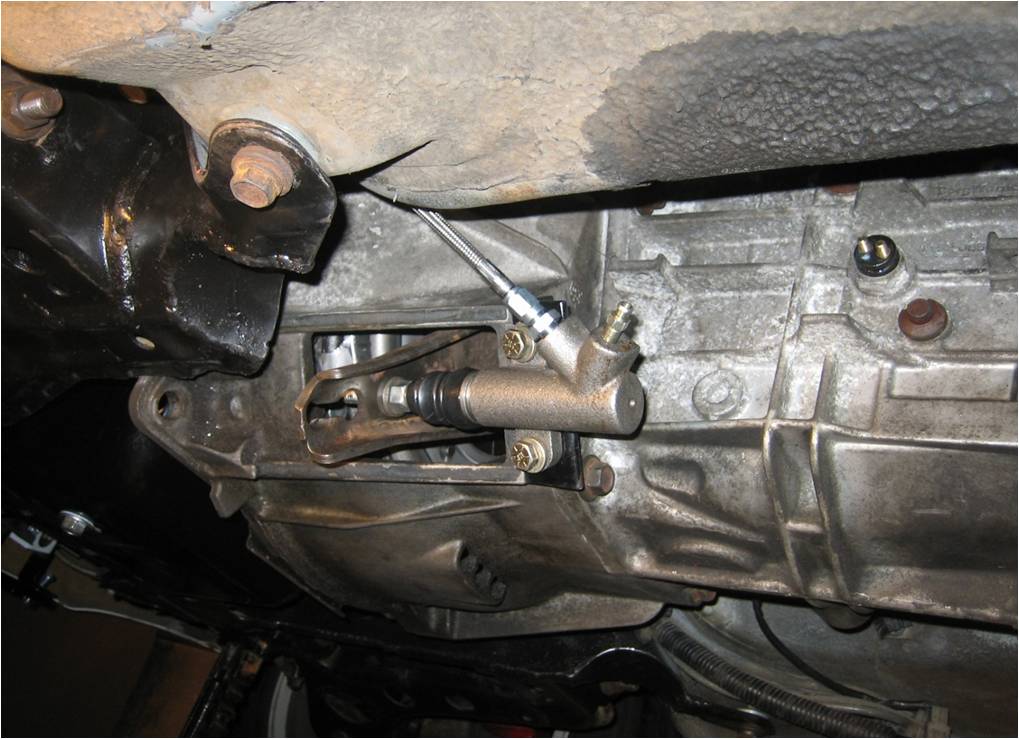

For what it's worth, the Tilton 6000 works great with my factory 1987 replacement clutch master cylinder.

However.. I can't recommend them due to the flat-face bearing they use is a proprietary design and they cost $50 each to replace. The bearing says "

MADE IN CHINA" on it also. I had my first one fail in under 2500 miles.

Now, could it have been set up (depth) incorrectly? I doubt it considering I measured and verified a dozen times with a known accurate, digital depth caliper before/during the install. After removal I inspected the bearing and it was very notchy feeling and was visually dry of grease. No visual signs of overheating though and no burnt grease smell. The pressure plate fingers were all good. Nice and even. But I bought another bearing to try again.

This time I started completely over by removing and cleaning everything first. Then I set total depth and verified several times. I also installed a new Ford Racing billet steel flywheel, RAM clutch, and RAM pressure plate, along with a new Ford pilot bearing and Ford flywheel dowel pins. By using new parts I hope to isolate the problematic part. So far the new bearing has made it 2000 miles, but I tried my best to pack it full of grease before install, because it also felt a little "different" to me while turning it in my hand. It had that "not a quality bearing" type of feel to it. It's now starting to make a faint whine or whirling sound when pushing the clutch pedal in. Just frgn great! I contacted Tilton and they stated they're only an engineering company and I'd just have to buy a new bearing from one of their distributors.

So, I'll say it again.

I CAN'T RECOMMEND TILTON 6000 SERIES HYDRAULIC RELEASE BEARINGS.

Which is a shame, because the unit is just a beautiful piece of billet artwork, and the lines are nicely made stainless AN that freely rotate for ease of installation.

Not trying to steal your thread, but I just wanted to share my experience thus far with my Tilton. Use at your own risk. In my opinion a clutch slave cylinder shouldn't have to be setup within a few thousandths of an inch. It should be built in a much more fool-proof manner, and durable enough to take a continuous load if necessary. Maybe using a conical bearing if possible..

Online reviewers seem happy with them, so maybe my case is an isolated incident, but I've been a mechanic/fabricator for over 25 years, so that doesn't seem likely.

GB