lowspeedpursuit

Active Member

- Joined

- May 6, 2022

- Messages

- 204

- Reaction score

- 150

- Points

- 43

- Location

- DE

- Vehicle Year

- 1994

- Make / Model

- B2300

- Engine Type

- 2.3 (4 Cylinder)

- Transmission

- Manual

- 2WD / 4WD

- 4WD

After finishing my 4wd swap on my '94, and taking it off-road for the first time, I drove across the county and back, and by the time I got home, I had a pretty bad grinding noise on takeoff. I had already rebuilt the trans (input shaft bearing) and the rear diff (twice, thanks Yukon). The noise wasn't as bad with the t-case in neutral, and the rear diff looked fine, so I bought some parts and pulled the transfer case. This case is from a '95, but I don't think there are super aggressive differences by year.

Bearings, Seals, Bushing, and Plastic Fork Guides:

https://www.transmissionpartsdistributors.com/bw1354-transfer-case-rebuild-kit-fits-bronco-ii-ranger-explorer-mazda-b-trucks-86-08-bk1354/

Chain:

https://www.rockauto.com/en/moreinfo.php?pk=10582420

https://www.amazon.com/dp/B09BYWX396 (this chain was cheaper, but it's out of stock right now)

The t-case is held in by the driveshafts (rear: 12mm 12pt) (aftermarket front: 13mm), speedo sensor (7/16"), 4x4 dash indicator wiring (on top, towards the trans), vent hose (behind the shifter linkage), and five bolts (13mm). You don't have to remove the shift linkage. The two bolts on the top are easier to reach by removing the floor panel over the trans, but you can get them from the bottom with an extension and swivel. The transfer case is light enough, and clocked far enough off horizontal, that it's easier to press it in and out yourself than to bother with a trans jack. Once it's out, pull the fill and drain plugs on the back and drain the fluid.

Then, you need to pull the output yokes (30mm,front requires "thin-wall"). Neither of mine needed a slide hammer. The service manual also says to pull the 4wd sensor at this time (7/8" deep). I didn't have a 7/8" deep, so I used vice grips. I also didn't have timely access to "thin-wall" sockets (and they apparently cost 3x as much anyway), so I bought a regular 30mm deep for $11 and clearanced the outside with an angle grinder and an impact driver. You don't need to remove very much material. I didn't want to impact with the modified socket, so I used a breaker bar, with a big pipe wrench holding the yoke. The last pic shows how the seals go on the output shafts.

At this point you can take out 9x bolts (15mm) and split the case. There are three pry points: top center, driver's edge, and bottom inline with the input and rear outputs. You can jam a 3/8" or 1/2" extension in at these points and wiggle it back and forth. My case didn't want to fully separate, so I also gently pried on the mating surfaces themselves--which is bad practice--using a flat screwdriver with tape over the end, wrapped in a paper towel. Finally, I smacked the front output shaft with a dead-blow hammer. As a result of pushing the front output shaft backwards, you can see that all the guts stayed in the rear half of my case. Per the service manual, you would expect the rear half to separate cleanly, and the guts to stay in the front. You can also see a fair amount of metal on my magnet, although nothing totally insane.

It looks like I didn't take a picture of the range fork removal, and the pics aren't great in general, but basically at this point you can just start taking shit apart. My disassembly is going to be in reverse of anyone whose guts stayed in the front half of their case. If you want to remove the oil pump from the main/output shaft, rotate the pump freely around the shaft until the notch on the pump lines up with the retaining pin on the shaft. At this point the pump will slide right off (thanks irate4x4), but you have to pull firmly. The pickup tube is attached to the pump with an ordinary spring clamp.

Now you can take the mostly empty front half of the case, flip it around, and remove 6x bolts (15mm) retaining the front face around the input shaft. It's RTV'd on, so I beat it with a dead-blow hammer around each of the ears. The face will come off with the input shaft and planetary assembly attached. A big snap ring with long tangs holds the face to the assembly via a groove in the input shaft bearing. When you spread the tangs with snap ring pliers, the face will fall off the input shaft.

Flip the assembly over so the input shaft is facing up. A large internal snap ring holds the input shaft to the planetary. Smack it around rotationally until one of the ends is in one of the notches, then you can get your snap ring pliers in there. Pry up underneath to get it started, then work the entire ring out and up, and remove the input shaft/sun gear assembly from the planetary.

Now the most difficult step of all the work I've done so far: getting the input shaft bearing off the input shaft. First, remove the external snap ring. Then, the service manual says to use a bearing puller, but mine shattered, and I've been jerry-rigging solutions ever since. For this, I held the bearing tightly in my vise with the input shaft pointing down, and hit the input shaft upwards from the bottom with a brass hammer. Popped right out.

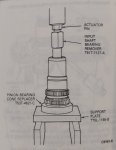

To make sense of the references in the last picture, as well as how everything fits together, here's the 1994 service manual's official exploded view and parts list:

That's as far as I got on the first day. I still need to pop the rest of the bearings and seals out of the case, test the oil pump, and figure out how to get the pocket needle bearing out of the inside of the input shaft. I might do that tomorrow, but reassembly is a ways away, since my new chain isn't scheduled for delivery until Monday.

I also need to assess whether the degree of play I have in the input shaft and planetary assembly is acceptable. I don't see any play specs in the manual, so input is welcome.

Bearings, Seals, Bushing, and Plastic Fork Guides:

https://www.transmissionpartsdistributors.com/bw1354-transfer-case-rebuild-kit-fits-bronco-ii-ranger-explorer-mazda-b-trucks-86-08-bk1354/

Chain:

https://www.rockauto.com/en/moreinfo.php?pk=10582420

https://www.amazon.com/dp/B09BYWX396 (this chain was cheaper, but it's out of stock right now)

The t-case is held in by the driveshafts (rear: 12mm 12pt) (aftermarket front: 13mm), speedo sensor (7/16"), 4x4 dash indicator wiring (on top, towards the trans), vent hose (behind the shifter linkage), and five bolts (13mm). You don't have to remove the shift linkage. The two bolts on the top are easier to reach by removing the floor panel over the trans, but you can get them from the bottom with an extension and swivel. The transfer case is light enough, and clocked far enough off horizontal, that it's easier to press it in and out yourself than to bother with a trans jack. Once it's out, pull the fill and drain plugs on the back and drain the fluid.

Then, you need to pull the output yokes (30mm,

At this point you can take out 9x bolts (15mm) and split the case. There are three pry points: top center, driver's edge, and bottom inline with the input and rear outputs. You can jam a 3/8" or 1/2" extension in at these points and wiggle it back and forth. My case didn't want to fully separate, so I also gently pried on the mating surfaces themselves--which is bad practice--using a flat screwdriver with tape over the end, wrapped in a paper towel. Finally, I smacked the front output shaft with a dead-blow hammer. As a result of pushing the front output shaft backwards, you can see that all the guts stayed in the rear half of my case. Per the service manual, you would expect the rear half to separate cleanly, and the guts to stay in the front. You can also see a fair amount of metal on my magnet, although nothing totally insane.

It looks like I didn't take a picture of the range fork removal, and the pics aren't great in general, but basically at this point you can just start taking shit apart. My disassembly is going to be in reverse of anyone whose guts stayed in the front half of their case. If you want to remove the oil pump from the main/output shaft, rotate the pump freely around the shaft until the notch on the pump lines up with the retaining pin on the shaft. At this point the pump will slide right off (thanks irate4x4), but you have to pull firmly. The pickup tube is attached to the pump with an ordinary spring clamp.

Now you can take the mostly empty front half of the case, flip it around, and remove 6x bolts (15mm) retaining the front face around the input shaft. It's RTV'd on, so I beat it with a dead-blow hammer around each of the ears. The face will come off with the input shaft and planetary assembly attached. A big snap ring with long tangs holds the face to the assembly via a groove in the input shaft bearing. When you spread the tangs with snap ring pliers, the face will fall off the input shaft.

Flip the assembly over so the input shaft is facing up. A large internal snap ring holds the input shaft to the planetary. Smack it around rotationally until one of the ends is in one of the notches, then you can get your snap ring pliers in there. Pry up underneath to get it started, then work the entire ring out and up, and remove the input shaft/sun gear assembly from the planetary.

Now the most difficult step of all the work I've done so far: getting the input shaft bearing off the input shaft. First, remove the external snap ring. Then, the service manual says to use a bearing puller, but mine shattered, and I've been jerry-rigging solutions ever since. For this, I held the bearing tightly in my vise with the input shaft pointing down, and hit the input shaft upwards from the bottom with a brass hammer. Popped right out.

To make sense of the references in the last picture, as well as how everything fits together, here's the 1994 service manual's official exploded view and parts list:

That's as far as I got on the first day. I still need to pop the rest of the bearings and seals out of the case, test the oil pump, and figure out how to get the pocket needle bearing out of the inside of the input shaft. I might do that tomorrow, but reassembly is a ways away, since my new chain isn't scheduled for delivery until Monday.

I also need to assess whether the degree of play I have in the input shaft and planetary assembly is acceptable. I don't see any play specs in the manual, so input is welcome.

Last edited: