- Joined

- Aug 6, 2007

- Messages

- 3,837

- Reaction score

- 1,672

- Points

- 113

- Location

- Macon/Fort Valley, GA

- Vehicle Year

- 1999

- Make / Model

- Ford

- Engine Type

- V8

- Transmission

- Automatic

- 2WD / 4WD

- 4WD

That "option" excludes anything that isn't a 4x4, rear primary drive, vehicle.It is almost that easy to do in a Ranger 4x4 (actually any 4x4 with part time transfer case works, easiest with automatic - less software to support shifting of manual):

Remove 4x4 transmission and transfer case (theoretically, we replace the 4.0 with 2.3 Duratec; a 1.5l Ecoboost Dragon would be even lighter/more compact but there might be some bellhousing issues, to save some weight/as we don't need power of 4.0. In place of transfer case we put a splitter to allow disconnecting rear axle when running in EV mode (might want to retain the low range gears for the box).Install electric motor where transfer case was, connect it to front axle driveshaft.Remove spare tire and carrier - install battery pack where the spare was. Install spare tire carrier in box ala Gen 2 Rangers with rear tank. If you want to get cute, put a charging jack where the rear tank filler would be so you can charge battery anywhere there is 110v power. (Really fancy you can set it up for Tesla chargers).Replace throttle pedal/cable with throttle by Wire, Replace the brake cylinder pin with spring/resistor one (needed for regenerative braking).You want electric a/c and steering, and hydro boost brakes. If I need heat in the morning, I'll run the ICE - using battery to heat coolant is extravagant use of electricity (but it might have advantage of keeping engine warm to reduce start up losses).Wire up black box under hood linking battery, motor, engine, throttle and brakes. The more you spend on software, the closer it will feel to OEM.The Ranger will start as front wheel drive EV, back out of the drive and quietly take you to work and back for pennies per km. If you need to drive clear across town, the ICE will kick in when battery gets low.When you're hauling load/towing trailer, you thumb the switch into tow/haul mode and Ranger runs primarily on ICE, with electric motor to assist in accelerating, hills, etc.In Sport mode, you get ICE and electric motor together (its also 4x4 mode).Performance and capability is more/less identical to the historic ICE truck.The challenge - the "conversion" is probably over $10k (maybe double that these days; I haven't actually costed it) - long time for payback...

Even then I don't think that's going to work out anything like you imagine. Even if you could install the parts as you suggest, the limited functionality would make it a wasted effort.

I've not looked at what Magna offers, but what is pictured is a non steering axle. It could only be used in place of a non steering beam type axle, which means a rear axle. It would work for a full EV conversion, but not much good for a hybrid. Maybe as an electric rear axle in a FWD vehicle, butost if those wouldn't have the room under the rear end for the axle or space for the batteries while the ICE drivetrain is still intact.Hybrid, or full EV retrofits would be much easier with something like the Magna EBeam:

You can't just split an EV battery easily to fit into an older chassis without giving up a lot of benefits and doing tons of work. That's why lots of these EV conversions that we see use unmodified battery packs from existing EVs. OEMs spend tens of thousands of man hours on controlling temps within EV batteries. The batteries have to be cooled/warmed at different times, under different conditions. Temps during charging and discharging are massively impactful to overall battery life. If you split a battery up to make it easier to package, then you have to set up all of that cooling/heating from scratch. Not just the hardware to do it (battery cases, coolant pumps/lines, etc), but the software as well (charging ramp rates, temperature management, throttling performance back over time, etc).

As for "splitting the battery pack" I never said it was easy, but it happens all the time in EV conversions. In fact I'd say it is more common to do that than to use the battery packs unmodified.

That's cool and what I was saying by make the batteries fit. The folks at ICON are hardly the only ones doing it, and they definitely weren't the first. Another example that is a little more practical IMO is the Z car recently built by throtl on YouTube. There have been a bunch more examples I've come across over the years, that's just about the easiest to provide.ICON are the only ones that I've seen who tackled splitting the battery up in their Tesla powered Mercury. They started with an 85kwh battery pack. Not sure if they still have the same capacity or not after splitting it up, but they estimate a 150-200 mile range which would be much lower than the ~260 mile range the Tesla would have with this battery pack. Some of that is worse aero, some of it comes from drivetrain inefficiency (driveshaft and ring/pinion differential) but I'm guessing a chunk of it also comes from splitting the battery up.

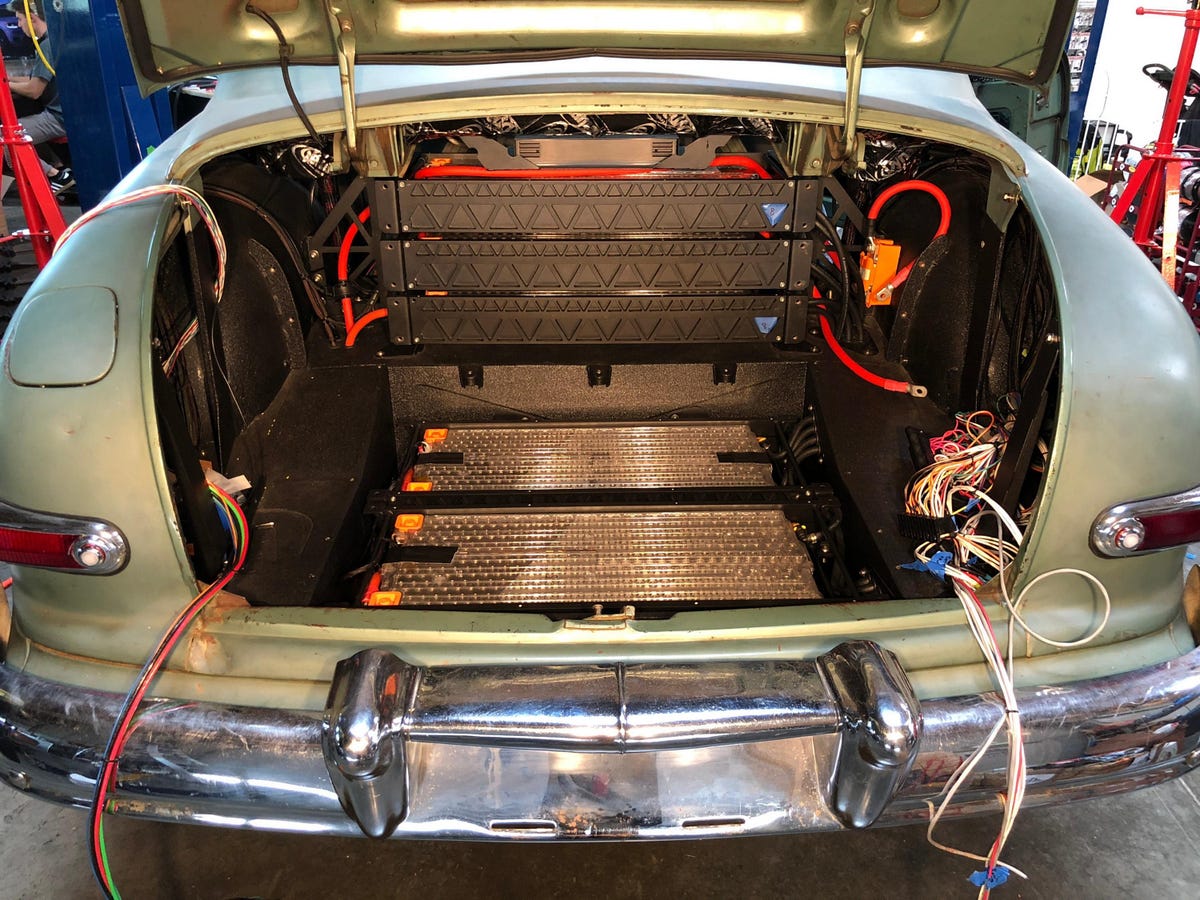

Again, they used a full custom chassis to make it all work together:

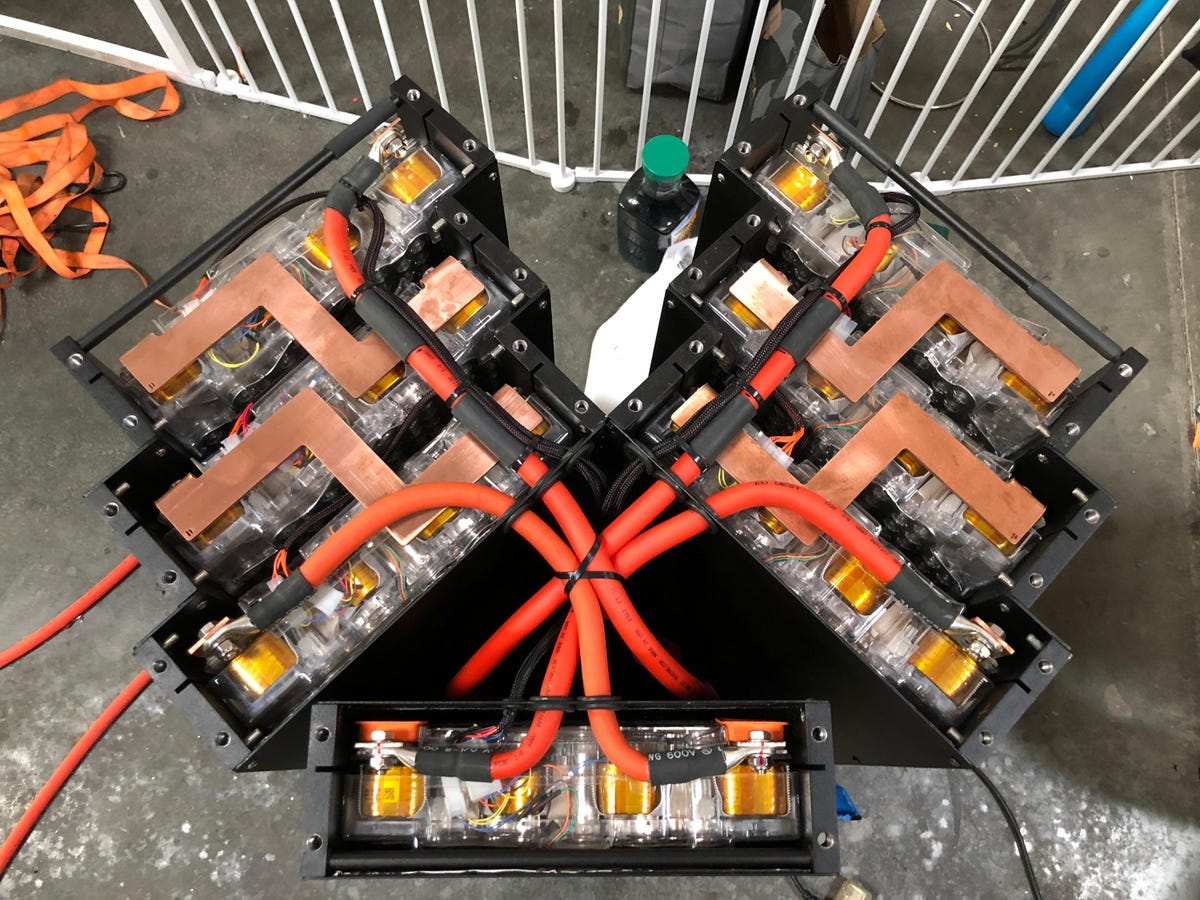

But they chose to split the battery, with some in the "engine" bay, and some in the trunk/passenger compartment:

As for the reduced range the points you make are valid. I'd say that they likely sacrificed some battery capacity in favor is styling. That car is probably driven 50-100 miles max per outing, probably half that, so they could give up capacity to fit the styling they were after.